Roll Aluminum Coil Michigan - AA8XXX Mill Finished Aluminum Coils D.C Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Description

AA8xxx Mill Finished Aluminum Coils D.C Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA8xxx Mill Finished Aluminum Coils D.C Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

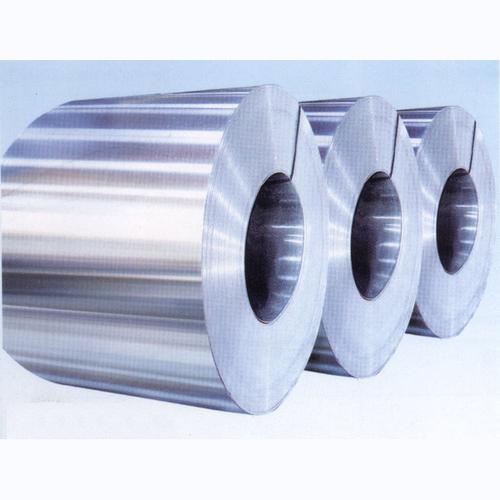

3.AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Images

4.AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Specification

| Alloy | AA8xxx (AA8011,AA8006 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32, O/F |

| Thickness | 0.2mm--100mm |

| Width | 30mm--1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum coils be used for food processing conveyor systems?

- Aluminum coils are a viable option for food processing conveyor systems. The food processing industry favors aluminum for its advantageous properties. To begin with, aluminum's lightweight nature facilitates effortless installation and transport. This aspect proves especially valuable for conveyor systems that necessitate frequent reconfiguration or relocation. Moreover, aluminum exhibits exceptional resistance to corrosion, a pivotal attribute in food processing environments where exposure to moisture, chemicals, and food particles is prevalent. Additionally, aluminum's hygienic attributes make it easy to clean and maintain, ensuring adherence to food safety standards. Lastly, aluminum coils can be effortlessly molded and customized to meet the specific requirements of conveyor systems, thereby facilitating efficient and effective food processing operations. Consequently, aluminum coils emerge as a fitting choice for food processing conveyor systems.

- Q: Can aluminum coils be customized in terms of thickness?

- Aluminum coils can indeed undergo customization in terms of thickness. The specific requirements of a particular application can determine the adjustment of aluminum coils' thickness. This customization is attained through the process of aluminum coil slitting, which involves cutting the original coil into narrower coils of the desired thickness. This method enables the flexibility to meet a range of needs and specifications across diverse industries.

- Q: What are the common sizes and dimensions of aluminum coils?

- Aluminum coils come in various sizes and dimensions, which are determined by the particular industry and application they are used in. While there are common dimensions that are used across different industries, specific requirements may vary. In the building and construction industry, aluminum coils are typically available in widths ranging from 24 inches (609.6 mm) to 60 inches (1524 mm). The thickness of these coils can vary from 0.019 inches (0.48 mm) to 0.032 inches (0.81 mm), although thicker gauges may be available for specialized applications. For the transportation industry, particularly in the manufacturing of automobiles and aircraft, aluminum coils are generally wider and thicker. Widths can range from 48 inches (1219.2 mm) to 72 inches (1828.8 mm), and thicknesses can vary from 0.035 inches (0.89 mm) to 0.125 inches (3.18 mm). In the food and beverage industry, where aluminum is commonly used for packaging purposes, the dimensions of aluminum coils tend to be smaller. Widths can range from 12 inches (304.8 mm) to 24 inches (609.6 mm), and thicknesses are usually around 0.006 inches (0.15 mm) to 0.020 inches (0.51 mm). It is important to keep in mind that these dimensions are not exhaustive and may differ based on the manufacturer and specific requirements of the application. Therefore, it is always advisable to consult with suppliers or manufacturers to determine the most suitable sizes and dimensions for your specific needs.

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for packaging in the pharmaceutical industry due to its excellent barrier properties, light weight, and resistance to corrosion. It provides a protective and hygienic environment for pharmaceutical products, ensuring their safety and extending their shelf life.

- Q: Can aluminum coils be used in the production of aluminum ceilings?

- Yes, aluminum coils can be used in the production of aluminum ceilings. The coils are typically processed and shaped into sheets, which are then used to create the ceiling panels.

- Q: How many companies have used aluminum coil?

- Too many. All the companies who make the aluminum products you have seen in daily life have used it. So it is hard to explain.

- Q: This question asks for guidelines on safely transporting aluminum coils, which are large and heavy metal rolls used in various industries.

- <p>To transport aluminum coils safely, follow these steps: Use specialized vehicles with proper securing mechanisms to handle the weight and prevent rolling. Ensure the coils are balanced and secured with straps or chains to avoid shifting during transit. Maintain a steady speed to minimize vibrations that could cause damage. Avoid sudden stops or sharp turns. Keep the load covered to protect from moisture and dirt. Adhere to all legal weight and dimension limits for your route. Regularly inspect the vehicle and load for any signs of damage or instability. Always follow local transportation regulations and safety guidelines.</p>

- Q: Classification of aluminium rolls for aluminium rolls

- On behalf of 6061, mainly contains two elements of magnesium and silicon, so it focuses on the advantages of the 4000 series and the 5000 series, and the 6061 is a cold treatment aluminum forging product, which is suitable for applications with high corrosion resistance and oxidation resistance.

- Q: What are the different coil winding options available for aluminum coils?

- There are several different coil winding options available for aluminum coils. These options include: 1. Single-layer winding: This is the most basic winding option where the wire is wound in a single layer around the coil. It is suitable for applications where space is limited and efficient cooling is required. 2. Double-layer winding: In this winding option, two layers of wire are wound on top of each other. This provides better heat dissipation and allows for higher power handling capacity. 3. Concentric winding: Concentric winding involves winding the wire in a series of concentric circles, with each layer of wire having a slightly different diameter. This type of winding is used to reduce the overall size of the coil while maintaining high inductance. 4. Litz wire winding: Litz wire is a type of wire made up of multiple strands, each individually insulated. This winding option is used to minimize skin effect and reduce power loss due to high-frequency currents. Litz wire winding is commonly used in high-frequency applications. 5. Toroidal winding: Toroidal winding involves winding the wire in a circular shape, creating a toroidal coil. This type of winding offers better magnetic field containment and reduced electromagnetic interference. 6. Layered winding: Layered winding involves winding the wire in multiple layers, with each layer insulated from the previous one. This type of winding is used when a high number of turns is required in a compact space. 7. Sectional winding: Sectional winding involves dividing the coil into different sections and winding each section separately. This allows for better control over the distribution of magnetic flux and reduces losses. Each of these coil winding options has its own advantages and is suitable for different applications based on factors such as power handling capacity, size constraints, and frequency requirements.

- Q: What are the common coil inner diameters for aluminum coils?

- The specific application and industry requirements can cause the common coil inner diameters for aluminum coils to vary. Nonetheless, 150 mm (5.9 inches), 200 mm (7.9 inches), and 300 mm (11.8 inches) are frequently utilized inner diameters for aluminum coils. These inner diameters are often selected considering factors like the coil's size, weight, ease of handling, and compatibility with manufacturing equipment. It is crucial to acknowledge that these examples are merely a few, and the actual inner diameters may differ based on the unique needs of each industry or application.

Send your message to us

Roll Aluminum Coil Michigan - AA8XXX Mill Finished Aluminum Coils D.C Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords