Fireclay Brick - RN 40 Brick Fired Furnace Brick Lining Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers.

Fire Clay Brick Features:

1.Good thermal stability,lowthermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Clay brick professional manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Advanced machine

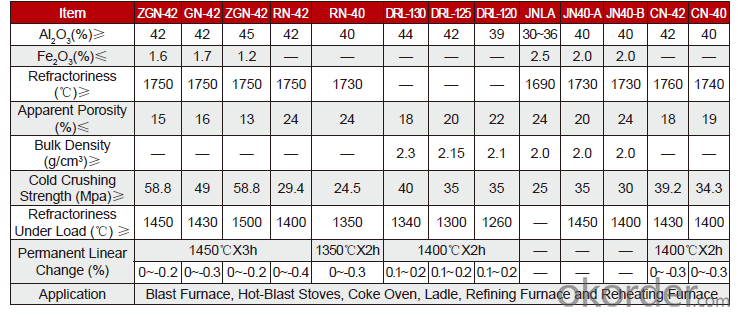

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: how much fireclay is needed for 10000 refractory bricks?

- The amount of mud used for T-3 refractory brick is 0.3KG. if the tiler is skillful, the furnace should have joint of 2mm.

- Q: How to choose the proper refractory bricks when buying the refractory bricks?

- Crack condition. 4. 6. Inspection of dimensions. Conditions of pits and swells and lack of edges or angles. The inspection of refractory bricks' appearance quality and the condition of the affecting with damp.

- Q: how heavy are boiler of six tons plus refractory bricks?

- The total weight is about 60 tons, 6 tons of bulk boiler steel, insulation materials, sealing materials, refractory material

- Q: What are the differences between thermal?insulation?bricks and refractory bricks?

- Thermal insulation brick has low fire resistance, generally is porous and light.

- Q: can the refractory sand be used to make refractory bricks?

- yes, a lot of refractory sand is made by broken refractory brick, they have the same function.

- Q: Do refractory bricks need to be sent to the lab to test after arriving the site?

- Generally speaking, as long as the use of temperature is not higher than 1500 degrees, it is not required to do the test, even if the ordinary refractory brick temperature is about 1500. If the temperature is high, then you do test to determine what kind of texture of refractory brick you need

- Q: The state's policy on clay bricks

- Now the country for the solid clay brick is the policy of emerge of itself and perish of itself. Because solid clay bricks occupy resources, vigorously encouraging new brick, I was open brick reached up to four, but we have to see this with money the disease I do, I don't think they all sold, finally want to engage in a new type of brick, but in the investigation that model free burning brick cost is too high, and a lot of people are not optimistic, finally did not dare to engage in this, we also have the business,

- Q: Can you direct the clay brick walls embryo

- Must not。 Not damp, damp, air tight, poor pressure bearing, bad adhesion between bricks and bricks

- Q: What are the main constituents in non clay brick sintering?

- According to the different production process of bricks into sintered brick and non sintered brick. Sintered brick in China has more than two thousand years of history, is still a very wide range of wall materials. Many kinds of brick, according to the raw materials used for clay brick, shale, coal gangue brick, fly ash brick, lime sand bricks and slag brick; according to the production process can be divided into sintered brick and non sintered brick, which can be divided into non sintered brick brick, autoclaved bricks and autoclaved brick etc.; according to whether the holes can be divided into ordinary bricks, porous brick, hollow brick.

- Q: The difference between clay bricks and clay bricks?

- According to the hole rate: solid brick (no hole or hole rate less than 25% bricks), porous brick (hole rate is equal to or greater than 25%), the size of the hole is small and the number of bricks, usually used in load-bearing parts, higher strength level. Hollow brick (hole rate equal to or greater than 40%, large pore size and small amount of brick, commonly used in non load parts, low strength grade).

Send your message to us

Fireclay Brick - RN 40 Brick Fired Furnace Brick Lining Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords