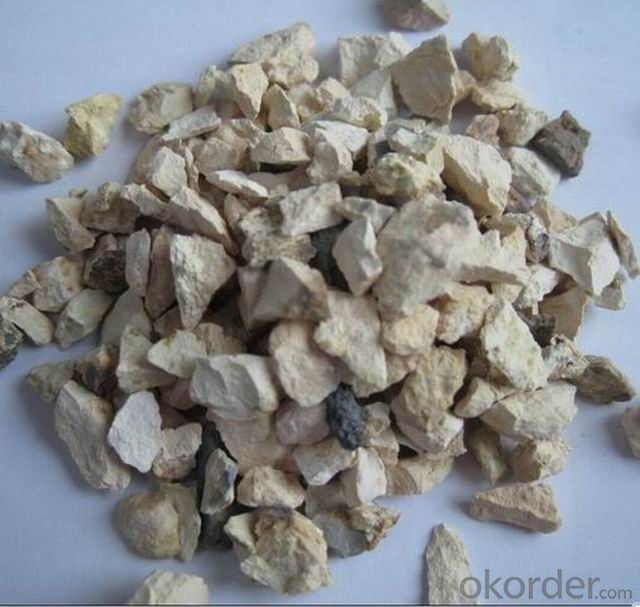

Raw Materials for Refractory:Calcined Bauxite Grade Size 1-3mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Block, block | Material: | Alumina Block |

| SiO2 Content (%): | <8%< p=""> | Al2O3 Content (%): | 75%-90% | MgO Content (%): | <0.5%< p=""> |

| CaO Content (%): | <0.5%< p=""> | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | 1-3mm | Brand Name: | cnbm |

| Color: | yellow, black and white | Application: | Refractory | Moisture: | 0.03% max |

| Bulk density: | ≥2.7g/cm3 | Model Number (Grade): | 75,80,85,86,87,88,90 | Sample: | Free sample of bauxite is available |

| Fe2O3: | 3.0% max | TIO2: | 0.4 max | K2O+NA2O: | 0.3 max |

Packaging & Delivery

| Packaging Details: | 25kgs/woven bag with PE liner bag 1000kgs in a big bag |

| Delivery Detail: | 7 days |

refractory grade size 1-3mm calcined bauxite

1. Calcined Bauxite 1-3mm brief introduction:

Calcined bauxite is a mixture of minerals that contain various concentrations of hydrated

aluminum oxides as well as impurities. The primary ore minerals are gibbsite (alumina tri-hydrate), boehmite and diaspore (alumina monohydrates).

2. Different grades calcined Bauxite 1-3mm tech datas:

Grade | AL2O3 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

75 | 75min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

80 | 80min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

85 | 85min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

86 | 86min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

87 | 87min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

88 | 88min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

90 | 90min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

3. Sizes available:

Grain size : 8-5mm, 5-3mm, 3-1mm, 1-0mm

powder: -320mesh, -280mesh, -240mesh, -200mesh,

-180mesh, -150mesh, -120mesh, -100mesh

320F 200F 280F 240F

200F 80F 150F 100F

4. Calcined Bauxite 1-3mm applications:

Aluminum smelting

Precision casting

Refractory products

Grinding materials

- Q: A chemical problem with refractory materials

- In chemistry, there is never absolute

- Q: The fire prevention board line is made of what material?

- Crural line: wooden, in the market, there are sjoiner woodblock, peach wood and artificial engraving. The second classification is stone and the most used one is the marble graved or ceramics well-made one is taken as the first choise. Its price is a little bit expensive than the wooden one, but also a suitable choise. Condole supports: It has various category. The general furniture choose plaster and anti-firing plate and the other also have a choice of steel. You can make a suitable choice according to the need. If it is contracting project, it depends on your project specific plan and funds plan. In a word, beauty and harmony should be given priority since it is the source of design.

- Q: What are the fire protection standards of insulation materials?

- The combustion performance of thermal insulation materials for exterior walls of all civil buildings, within the scope of fire design auditing and fire control acceptance, should be brought into the auditing and acceptance. As for the "Management Regulations on Supervisions of Fire Prevention and Control for Building Projects" (Ministry of Public Order No. 106) , all civil buildings which are out of the scope of Article 13 and 14 are included in the random check. Before the release of new standard, it must be strictly implemented the Article II of the "Fire prevention Interim Provisions on civil external wall insulation system and external wall decorative" ([2009] No. 46), namely, the insulation materials of civil buildings must use materials with A-level combustion performance.

- Q: How can refractory materials be divided?

- Refractory materials in China can be roughly divided into refractory products and unshaped refractories.

- Q: What refractories are accessible with ease in daily life?

- Refractory mortar. Thermal insulation refractory materials include diatomite products, refractory castables, monolithic?refractories, carborundum bricks, gun-mix refractories, semi-silica bricks, borides, beryllia, silicide, calcium oxide, high alumina refractory brick, refractory coatings, corundum bricks, fireclay?bricks, silicon nitride bonded silicon carbide bricks, chromium hemitrioxide and other refractories. What refractories can be found mostly in the market? Common refractories. Common refractories include silica bricks. The mostly used unshaped refractories include fettling, ramming refractories, castable refractories, plastic refractories, refractory clay, gun-mix refractory, sling refractories, refractory coatings, lightweight refractory castables, stemming etc. The mostly used insulating refractories include diatomite products, asbestos products, insulation panels, etc. The mostly used special refractories include AZS bricks.

- Q: who knows how to classify the fire resistant levels of fireproofing material?

- Grade of fireproofing material: Class A: Incombustible building material, almost without burning. class A1: Non-combustible, no open flame,class A2: Non-combustible,it needs to measure smoke and be qualified. Class B1: Nonflammable building material: Nonflammable materials have good flame resistance function. when it contacts open fire or is under high temperature, it's difficult to burn and be spreading rapidly, and will stop burn after removing the combustion?source. Class B2: Combustible?building?materials: Combustible materials have good flame resistance function. when it contacts open fire or is put in the air at high temperature, it will immediately burst into flames, and easily result in the spreading of fire, such as wooden column, timber roof truss, timber beam, wooden stairs, etc. Class B3: Inflammability building materials, without any flame resisting effects, easy to burn, and has large danger of fire disaster.

- Q: Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q: Pals who know something about fire resistant material please tell me how many types of refractory material there are

- There are a variety of refractory materials, each of different use. It is necessary to make resonable classification for refractory materials so as to facilitate scientific research, rational selection and management. There are many kinds of classification methods for refractory materials, including classification based on chemical property, chemical mineral composition, production process, material form and other methods. 1, according to the capacity of fire resistance: ordinary refractory materials: 1580 degrees C ~1770 C Advanced Refractory Materials: 1770 degrees ~2000 degrees c: Classification according to product shape and size: standard 230mm×113mm×65mm no more than 4 scales

- Q: What is the the best ratio of mortar in refractory cement?

- Specifical proportions are as following: 42.5R cement is 425 rapid hardening cement. Using the 425 cement to compound the mortar. The reducion of cement will naturally impact the workability of the mortar. The mix design standard of the mortar specifies the minimum amount of cement is not less than 200kg / m3. If it is composite mortar, and the strength and workability can be ensured, it is Ok to use 425 to compound. You can look for instructions of mixing proportion of mortar online as a reference.

Send your message to us

Raw Materials for Refractory:Calcined Bauxite Grade Size 1-3mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords