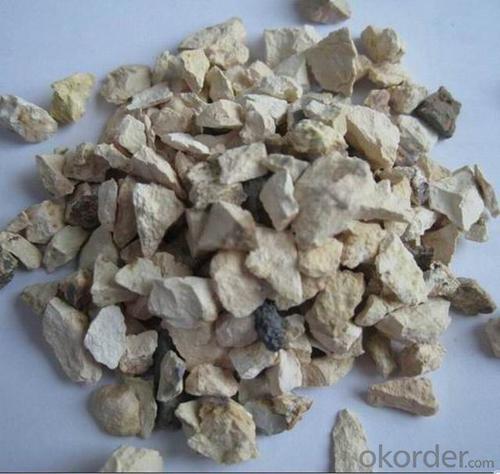

Raw Materials for Refractory:Calcined Bauxite 75-90 Grade Size 1-3mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Block | Material: | Alumina Block |

| SiO2 Content (%): | <8% | Al2O3 Content (%): | 75%-90% | MgO Content (%): | <0.5 |

| CaO Content (%): | <0.5 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.0 |

| SiC Content (%): | 0.0 | Model Number: | 75,80,85,86,87,88,90 | Brand Name: | CNBM |

| Fe2O3: | 3.0 max | K2O+NA2O: | 0.3 max | TIO2: | 0.4 max |

| CaO+MgO: | ≤0.5 | shapes: | granula and powder | bulk density: | ≥2.70 |

| H.S.code: | 2508300 | Moisture: | 0.03% max | color: | yellow,black and white granula and powder |

| application: | abrasive ,cement ,chemical, metallurgical, and refractory and so on |

Packaging & Delivery

| Packaging Details: | 25kg/Bag,1Mt/Bag,1.25Mt/Bag; Or as per Client's request |

| Delivery Detail: | 7-15 days upon receipt of prepayment by TT or L/C |

Specifications

Calcined bauxite:

14 years producing experience;

self-owned mines;

SGS or BV report.

Calcined bauxite specification:

Grade | AL2O3 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

75 | 75min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

80 | 80min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

85 | 85min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

86 | 86min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

87 | 87min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

88 | 88min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

90 | 90min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | |

Size: as buyer’request

Packing: usually we packing in big bag, 1.25mt/bag; we could pack as buyer’request

Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns.

Applications

calcined bauxite is typically calssified according to its intended commercial application,such as abrasive ,cement ,chemical, metallurgical, and refractory .as raw material for use in high alumina and super duty refratory bricks and shapes ,plastics ,castable refratory, motors, gun mixes, ramming mixes, abrasive grains and other products.

- Q: How to distinguish the construction fire-proof material rating?

- Each country has its own fireproof standards, so I do not know which country you are in ? Each country has different division levels of fireproof materials, such as GB 8624, German standard DIN 4102-1, British standard BS 476, France standard NF P92-501 and so on. GB 8624 Chinese building materials and products combustion performance division levels fireproof resources network (FireTC.

- Q: Application of refractory materials in petroleum industry

- Our natural gas transportation, chemicals, equipment, packing, safety, insulation, and even building materials are available.

- Q: Can anyone say something about the curtain wall fire-proof material key sealing point?

- Hello. 1. Gaps between the curtain walls and floors of all tier and partitions outer edge should be sealed with non-combustible material or flame retardant materials. Filling material can be rock wool or mineral wool, whose thickness should be not less than 100mm and should meet the designed fire endurance requirements, forming fire and smoke prevention areas between floors and rooms. Fireproof layer should use galvanized steel bearing with thickness of not less than 1. 5mm, and should not use aluminum plate. Gaps between bearing plate and main structure, curtain wall structure and the bearing plate should be sealed by fireproof sealant; fireproof sealant should has fireproof inspection reports granted by statutory testing organizations. 2. When building designs requiring transparent effect of fire compartment and separation, monolithic fire-resistant glass or hollow and laminated fire-resistant glass nade by monolithic fire-resistant glass can be adopted. 3. Windowsills-free curtain walls, incombustible entities skirt wall or fireproof glass wall whose fire endurance is not less tan 1.0 hour and height is not less than 0.8m should be set on the outer edge of each floor. The thickness of reinforced concrete floor or height of the side beams should be counted when calculating the height of the skirt wall. 4. Fire protection layer should not contact directly with the glass curtain wall, and the side towards the glass of fireproof materials should be covered with the decorative material. 5. Glass units of the same curtain wall should not cross two fire?compartments.

- Q: What is the role of the vermiculite fireproof material?

- The vermiculite fireproof slate is widely applied to construction, shipbuilding, metallurgy, electric power, aerospace and other fields by foreign countries. Vermiculite slate can be applied to furniture, firewall, ceiling, and can be used in the fire fighting access, coated steel, coated pipeline, real flame fireplace in the lining board, wall partition. It is characterized by non combustible, non melting, resistance to high temperature; permanent thermal insulation; sound insulation, non-toxic, smoke-free, green environmental protection; resistance to impact, good dimensional stability and durability of the excellent anti fungal infestation. It can be sawed, nailed, planed, drilled, it can be easily installed and constructed.

- Q: who knows the fire resistant level of fireproof gypsum board ?

- The most commonly used ceiling decoration materials rates B1, including gypsum board, fibrous plaster, cement particle board, mineral wool sound-absorbing panels, glass wool decorative acoustic?panel?absorber, perlite decorating acoustic board, nonflammable plywood, nonflamable medium density fiberboard, mineral wool decorative board, flame retardant wood, aluminum foil composites, flame retardant phenolic plywood, aluminum foil glass fiber reinforced plastic composite materials. The fire gypsum board fire rating can reach A. Of course, many of the suspended ceiling gypsum board of inferior quality rates below B1. plasterboard is non-flammable B1 level products. There are introductions in Fireproof Specification of National Standard Building Interior Decoration Design. plaster board mounted on steel stud can be used as A level decoration materials. in accordance with the national fire safety rules on fire durance of walls and ceilings and other components. we can not simply say whether a piece of gypsum board can meet the requirements.

- Q: Does anyone know fire-proof material of fireproof wooden door?

- Because the timber of fireproof wooden door has gone through fire retardant treatment, so it can prevent fire. Its principle: Fire-retardant treated timber has become flame retardant material itself and its fire endurance has increased. The commonly used method of fire retardant treatment for timber including: Spraying method, soaking method, boiling method, vacuum method, vacuum-pressure method. Spraying method and soaking method are generally used for timber surfaces which are no longer going through planing process, and thin plate fire retardant treatment, whose thickness is less than 10mm . Vacuum method and vacuum-pressure method have excellent flame retardant efficiency, but their equipment are expensive. Fireproof wooden door refers to the door whose fire endurance of door frames, skeleton of the door leaf, door panels made of timber or timber work reaches the provisions of "GB50045-95 design of tall buildings for fire protection".

- Q: What is the the best matching ratio of refractory cement?

- The ratio of cement and sand is about 30 per cent. Properties and Applications of refractory mortar: 1, Good plasticity and easy construction; 2, High bonding strength and strong corrosion resistance; 3, Relatively high refractoriness up to 1650 ℃ ± 50 ℃; 4, Good slag corrosion resistance; 5, Good thermal peeling. Refractory mortar is mainly used in coke ovens, glass furnaces, hot blast furnace and other industrial furnaces. Applied industry: Metallurgy, building materials, machinery, petrochemicals, glass, boiler, electric power, steel, cement, etc. And refractory cement is also known as aluminate cement. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement. Aluminate cement is often yellow or brown or gray. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc. It is a special cement.

- Q: how to classify the fireproofing material levels A1 A2 B1?

- their classification is shown specifically in Fireproof? Specification of Building Interior Decoration?Design GB 50222-95 appendix A, flammability,inflammability materials, flame retardency, noninflammability: combustion performance of A, B3, B2, B1 materials are divided into

- Q: Pals who know something about fire resistant material please tell me how many types of refractory material there are

- There are a variety of refractory materials, each of different use. It is necessary to make resonable classification for refractory materials so as to facilitate scientific research, rational selection and management. There are many kinds of classification methods for refractory materials, including classification based on chemical property, chemical mineral composition, production process, material form and other methods. 1, according to the capacity of fire resistance: ordinary refractory materials: 1580 degrees C ~1770 C Advanced Refractory Materials: 1770 degrees ~2000 degrees c: Classification according to product shape and size: standard 230mm×113mm×65mm no more than 4 scales

- Q: Does the aluminum silicate thermal insulation material fireproof?

- it can be fireproof and has a strong fireproof?performance.

Send your message to us

Raw Materials for Refractory:Calcined Bauxite 75-90 Grade Size 1-3mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords