All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Discuss the significance of creep testing in evaluating refractory behavior under stress.

Creep testing is crucial in evaluating the behavior of refractory materials under stress because it helps to determine their deformation and stability over time. Refractory materials are commonly exposed to high temperatures and mechanical stresses in various industries, such as metallurgy and ceramics. The ability of these materials to resist deformation and maintain their structural integrity over prolonged periods is essential for their performance and longevity.

Creep testing involves subjecting refractory specimens to constant stress at elevated temperatures for extended durations. By measuring the time-dependent deformation or strain, creep testing provides valuable insights into the material's behavior under sustained loading conditions. This information is critical for designing and selecting refractory materials that can withstand the demanding operating conditions they are exposed to.

The significance of creep testing lies in its ability to assess the long-term performance and reliability of refractories. It allows engineers and researchers to understand the material's creep rate, which is the rate at which it deforms over time, and its creep resistance, which is its ability to resist such deformation. Creep testing also helps in identifying the presence of any time-dependent failure mechanisms, such as grain growth or phase transformations, that can lead to premature and catastrophic material failure.

Additionally, creep testing aids in evaluating the effects of temperature, stress, and environmental factors on refractory behavior. This information helps in optimizing the selection and formulation of refractory materials for specific applications, ensuring their suitability and durability in high-stress environments.

In summary, creep testing plays a significant role in evaluating refractory behavior under stress by providing crucial data on deformation, stability, and failure mechanisms over extended periods. This information is essential for designing, selecting, and improving refractory materials to meet the demanding requirements of various industries.

What is the purpose of alumina nanoparticles in refractory materials?

The purpose of alumina nanoparticles in refractory materials is to enhance the mechanical strength, thermal conductivity, and overall performance of the refractory. Alumina nanoparticles help to improve the resistance of refractory materials against high temperatures, chemical corrosion, and wear. Additionally, they contribute to the stabilization of microstructure and improved densification of refractory materials, making them more effective in withstanding extreme conditions and extending their lifespan.

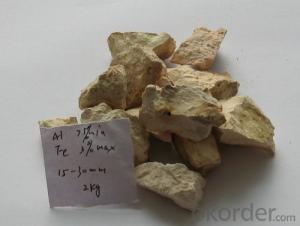

What are the different grades of alumina used in refractory applications?

The different grades of alumina used in refractory applications vary based on their purity level and particle size distribution. Common grades include high purity alumina (HPA), tabular alumina, fused alumina, and calcined alumina. HPA, with a purity of 99.9% or higher, is typically used in high-temperature applications requiring excellent thermal conductivity and resistance to corrosion. Tabular alumina, known for its high refractoriness and thermal shock resistance, is commonly used in high-temperature furnace linings. Fused alumina, produced by melting high-grade alumina in an electric arc furnace, is utilized in applications requiring high abrasion resistance. Calcined alumina, derived from the calcination of alumina hydrate, is often used as a refractory filler or as a component in specialized refractory materials.

Which refractory raw materials are suitable for basic environments?

Some refractory raw materials that are suitable for basic environments include magnesia, dolomite, chromite, and spinel.

Wholesale Raw Materials For Refractory from supplier in Guatemala

Our team of experts is dedicated to providing excellent customer service and ensuring that you have a smooth and hassle-free experience when purchasing Raw Materials For Refractory. We understand the importance of timely delivery and maintaining consistent quality, which is why we work closely with our suppliers to ensure that the materials meet the highest standards.

In addition to our wide range of products, we also offer technical support services to assist you in selecting the most suitable materials for your specific applications. Our team can provide guidance on product selection, usage, and optimization to help you achieve the best results.

We take pride in our commitment to sustainability and environmental responsibility. We strive to source our materials from reputable suppliers who adhere to strict ethical and environmental standards. By choosing our Raw Materials For Refractory, you can be confident that you are making a responsible choice for your business and the environment.

At our company, we believe in building long-term partnerships with our clients. We are dedicated to providing reliable and cost-effective solutions to meet your needs. Whether you require a small order or a large-scale supply, we are here to support you every step of the way.

Contact us today to learn more about our Raw Materials For Refractory and how we can assist you with your procurement needs in Guatemala. We look forward to serving you and becoming your trusted supplier in the region.

In addition to our wide range of products, we also offer technical support services to assist you in selecting the most suitable materials for your specific applications. Our team can provide guidance on product selection, usage, and optimization to help you achieve the best results.

We take pride in our commitment to sustainability and environmental responsibility. We strive to source our materials from reputable suppliers who adhere to strict ethical and environmental standards. By choosing our Raw Materials For Refractory, you can be confident that you are making a responsible choice for your business and the environment.

At our company, we believe in building long-term partnerships with our clients. We are dedicated to providing reliable and cost-effective solutions to meet your needs. Whether you require a small order or a large-scale supply, we are here to support you every step of the way.

Contact us today to learn more about our Raw Materials For Refractory and how we can assist you with your procurement needs in Guatemala. We look forward to serving you and becoming your trusted supplier in the region.

Hot Search

- Monolithic Refractories in Morocco

- Ceramic Fiber Products in Eritrea

- Refractory Bricks in Portugal

- Raw Materials For Refractory in Luxembourg

- Raw Materials For Refractory in Senegal

- Ceramic Fiber Products in Belarus

- Monolithic Refractories in Canada

- Monolithic Refractories in Monaco

- Monolithic Refractories in Seychelles

- Raw Materials For Refractory in Ireland