All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

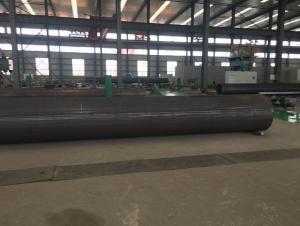

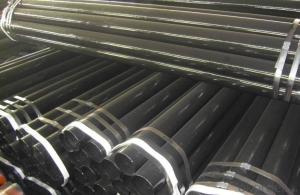

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can a welded steel pipe be used for water distribution systems?

Yes, a welded steel pipe can be used for water distribution systems. Welded steel pipes are commonly used in water distribution systems due to their durability, strength, and resistance to corrosion. They can efficiently transport water over long distances and are suitable for both aboveground and underground installations. Additionally, welded steel pipes can withstand high pressure and temperature variations, making them a reliable choice for water distribution systems.

Can welded steel pipe be used for building hydroelectric plants?

Yes, welded steel pipe can be used for building hydroelectric plants. Welded steel pipes are commonly used in the construction of hydroelectric plants due to their high strength, durability, and resistance to corrosion. These pipes can effectively transport water and withstand the high pressures and flow rates associated with hydroelectric power generation.

Are welded steel pipes suitable for paper mills?

Yes, welded steel pipes are suitable for paper mills. Welded steel pipes have excellent strength and durability, making them ideal for transporting various materials, including water, chemicals, and steam, which are commonly used in paper mills. Additionally, welded steel pipes are resistant to corrosion, ensuring the longevity and reliability of the pipelines within the paper mill environment.

What are the factors to consider when designing a pipeline using welded steel pipes?

When designing a pipeline using welded steel pipes, several factors need to be considered. First and foremost, the material properties of the steel pipes, such as their strength, corrosion resistance, and ductility, should be evaluated to ensure they meet the requirements of the intended application. Additionally, the diameter, wall thickness, and length of the pipes must be determined based on the flow rate, pressure, and expected load conditions to ensure structural integrity and prevent leakage. The welding process and technique used should also be carefully selected to ensure proper joint strength and integrity. Furthermore, factors such as the terrain, environmental conditions, and potential external forces, such as seismic activity or ground movement, must be taken into account to ensure the pipeline's stability and durability. Lastly, considerations such as cost, availability, and ease of installation should be weighed to ensure an efficient and cost-effective pipeline design.

Are there any regulations or codes governing the use of welded steel pipes?

Yes, there are regulations and codes that govern the use of welded steel pipes. These regulations and codes ensure the safe and standardized use of welded steel pipes in various industries and applications. They cover aspects such as material specifications, welding processes, quality control, and inspection requirements to ensure the integrity and reliability of the welded steel pipes.

Wholesale Welded Steel Pipe from supplier in Guatemala

Our commitment to quality and customer satisfaction sets us apart as a trusted supplier of Welded Steel Pipe in Guatemala. With our comprehensive range of products and dedicated support services, we can cater to diverse applications and industries. As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide a one-stop solution for all your Welded Steel Pipe procurement requirements.

We have a deep understanding of the Guatemalan market and its specific requirements and challenges. This knowledge allows us to offer personalized recommendations and support, ensuring the success and efficiency of your projects. Our team of experts is always available to provide technical assistance and guidance throughout your project.

When you choose us as your Welded Steel Pipe supplier, you can expect exceptional service and reliable products. We prioritize customer satisfaction and are dedicated to delivering on-time and within budget. Partner with us for all your Welded Steel Pipe needs in Guatemala and experience the difference of working with a trusted and reliable supplier.

We have a deep understanding of the Guatemalan market and its specific requirements and challenges. This knowledge allows us to offer personalized recommendations and support, ensuring the success and efficiency of your projects. Our team of experts is always available to provide technical assistance and guidance throughout your project.

When you choose us as your Welded Steel Pipe supplier, you can expect exceptional service and reliable products. We prioritize customer satisfaction and are dedicated to delivering on-time and within budget. Partner with us for all your Welded Steel Pipe needs in Guatemala and experience the difference of working with a trusted and reliable supplier.