Rectangular Hot Rolled Steel Tube With Reasonable Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Quick Details

Thickness: | 1.0 - 35 mm | Section Shape: | Square | Outer Diameter: | 20*20-600*600 |

Place of Origin: | Shandong China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe |

Technique: | Cold Rolled | Certification: | CE | Surface Treatment: | oil,paint |

Special Pipe: | Thick Wall Pipe | Alloy Or Not: | Non-alloy | Name: | Square Hollow Steel Pipe/Tube |

Shape: | Square/Rectangular | Yield Strength: | 360-380Mpa | Tensile Strength: | 560-580Mpa |

Elongation: | 24-28% | Bend Test: | Qualified | Impact Value: | V-notch |

Grade: | 20#,45#,16Mn,A210,St45,Q235,Q345,Q195,Q215,10#-45#,A53-A369,ST35-ST52,Q195-Q345 | Standard: | JIS G3465-2006,JIS G3466,GB/T 3094 |

2.Specifications

1. OD:15X15-800X800MM,20X30--600X800MM

2. Thick.:1.0--35.0MM

3.FAQ of Rectangular Steel Tube

①How is the quality of your products?

If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

We have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you have any question, pls feel free to contact us !

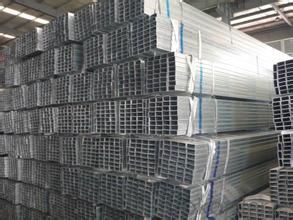

4.Rectangular Hot Rolled Steel Tube Image

- Q: What is the standard length of steel pipes?

- The standard length of steel pipes varies depending on the industry and application, but common lengths range from 10 to 40 feet.

- Q: What are the safety considerations when working with steel pipes?

- When working with steel pipes, safety considerations include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to prevent injuries. It is essential to handle and lift steel pipes using proper techniques and equipment to avoid strains and falls. Ensuring a clean and organized work area, as well as securing pipes to prevent rolling or tipping, reduces the risk of accidents. Additionally, workers should be cautious of sharp edges and ensure proper ventilation when working with welding or cutting tools to minimize the risk of fires or inhalation hazards.

- Q: How are steel pipes protected against underground corrosion?

- Steel pipes are protected against underground corrosion through a process called cathodic protection. This involves the use of sacrificial anodes or impressed current systems, which help to create a protective electrical current that prevents the steel from corroding. Additionally, coatings and wraps are applied to the pipes to provide an additional layer of protection against corrosion.

- Q: What are the different methods of measuring the thickness of steel pipes?

- There are several methods of measuring the thickness of steel pipes. One common method is using ultrasonic thickness gauges, which send high-frequency sound waves through the pipe and measure the time it takes for the waves to bounce back. Another method is through magnetic induction, which uses a magnetic field to determine the thickness based on the changes in the field caused by the pipe's thickness. Additionally, there are mechanical methods such as using calipers or micrometers to directly measure the thickness of the pipe.

- Q: How do you calculate the maximum allowable deflection for steel pipes?

- When calculating the maximum allowable deflection for steel pipes, various factors must be taken into account. These factors include the pipe diameter, material properties, support conditions, and desired level of deflection. The maximum allowable deflection is typically determined according to industry standards and codes. One popular method for calculating the maximum allowable deflection is based on the pipe's span-to-diameter ratio, also known as the L/D ratio. The L/D ratio is calculated by dividing the pipe's span (the distance between supports) by its diameter. Numerous industry codes provide guidelines for the maximum allowable deflection based on the L/D ratio. For instance, the American Society of Mechanical Engineers (ASME) B31.1 Power Piping Code suggests that for carbon steel pipes, the maximum allowable deflection should not exceed 3% of the pipe's span when the L/D ratio is 100 or less. However, as the L/D ratio increases, the deflection limit decreases to ensure the pipe's stability and structural integrity. To calculate the maximum allowable deflection using the L/D ratio method, you first need to determine the L/D ratio based on the pipe's span and diameter. Then, you can refer to the applicable code or standard to find the corresponding maximum allowable deflection limit. It's important to note that other factors, such as the pipe material's yield strength, wall thickness, and the type of loading (e.g., dead load, live load), also influence the maximum allowable deflection. Therefore, it is crucial to consult the relevant industry standards, codes, and engineering principles to accurately calculate the maximum allowable deflection for steel pipes.

- Q: What is the buckling type thin-wall steel pipe? What is a tight set of thin-walled steel tubes? What's the difference between the two?

- The wire pipe thread (box, cup lock fastening points) (JDG) and buckling type (KBG) two. Products are made of high-quality steel pipe, through precise stamping molding, supply pipe and terminal box connection. The nut is hexagonal, and the convex point is punched at the six corner so as to form a good multi-point contact after being connected with the junction box.

- Q: Can steel pipes be painted?

- Yes, steel pipes can be painted. Painting steel pipes not only enhances their appearance but also provides protection against corrosion and rust. The process typically involves cleaning the pipes thoroughly, applying a primer, and then coating them with a suitable paint.

- Q: Is the steel frame on each floor supporting formwork (floor) called full scaffolding?

- The scaffold is also called full house scaffolding is a construction process for building a scaffold. Hall scaffolding relative to other scaffolding system density, that is, the house full of shelves. The full scaffolding is more secure than the rest of the scaffolding.

- Q: What is the difference between seamless steel pipes and seamless alloy steel pipes?

- The main difference between seamless steel pipes and seamless alloy steel pipes lies in their composition. Seamless steel pipes are made from carbon steel, which is primarily composed of iron and carbon. On the other hand, seamless alloy steel pipes are made from a combination of carbon steel and various alloying elements such as chromium, nickel, or molybdenum. These alloying elements enhance the properties of the steel, making it more resistant to corrosion, heat, and pressure. They also provide improved strength and durability, making alloy steel pipes suitable for applications that require high performance and reliability. In summary, while both seamless steel pipes and seamless alloy steel pipes are used for various industrial applications, alloy steel pipes offer superior performance due to their alloying elements, making them more suitable for demanding conditions.

- Q: Can steel pipes be used for underground utility lines?

- Yes, steel pipes can be used for underground utility lines. Steel pipes are commonly used for various underground applications, including utility lines for water, gas, and sewage. They are durable, strong, and resistant to corrosion, making them suitable for long-term use in underground environments. Additionally, steel pipes can be easily welded and connected, allowing for efficient installation and maintenance.

Send your message to us

Rectangular Hot Rolled Steel Tube With Reasonable Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords