Raw Materials for Refractory:Black Silicon Carbide for Abrasives and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | silicon carbide | Model Number: | silicon carbideF4-f240 |

| Material: | silicon carbide | Usage: | abrasive for grinding ball,refractory material, | Abrasive Grain Sizes: | F4-F240 |

| silicon carbide: | black |

Packaging & Delivery

| Packaging Details: | 25 kg bags on pallet up to 1 ton 1 ton loose in big bag |

| Delivery Detail: | 15days |

Product Description

Products Picture

Black silicon carbide consists of crystalline silicon carbide, which is produced from silica sand and petroleum coke in electric resistance furnaces at temperatures of > 2.300 °C. Silicon carbide is iron-free, angular and extremely hard.

Applications:

Reusable abrasive

Grinding, lapping and polishing medium

Grinding wheels and grinding medium

Wear-resistant and refractory products

Blasting systems:

Pressure blast systems

Injection blast cabinets

Speciafication

| Typical physical properties | |

| Hardness | approx. 9 - 10 mohs |

| Grain shape | angular |

| Melting point | approx. 2300 °C |

| Specific gravity | approx. 3,2 g/cm3 |

| Bulk density (depending on granular size) | approx. 1,3 – 1,5 g/cm3 |

| Typical chemical analysis | |

| SIC | 98,00 % |

| Fe2O3 | 0,24 % |

| C-frei | 0,50 % |

| Magnetic particles | 0,12 % |

| Available sizes | |||

| FEPA | Average grain size | ||

| ds3-Factor max. μm | ds50-Factor μm | ds94-Factor min. μm | |

| F 230 | 82,0 | 53,0 +/– 3,0 | 34,0 |

| F 240 | 70,0 | 44,5 +/– 2,0 | 28,0 |

| F 280 | 59,0 | 36,5 +/– 1,5 | 22,0 |

| F 320 | 49,0 | 29,2 +/– 1,5 | 16,5 |

| F 360 | 40,0 | 22,8 +/– 1,5 | 12,0 |

| F 400 | 32,0 | 17,3 +/– 1,0 | 8,0 |

| F 500 | 25,0 | 12,8 +/– 1,0 | 5,0 |

| F 600 | 19,0 | 9,3 +/– 1,0 | 3,0 |

| F 800 | 14,0 | 6,5 +/– 1,0 | 2,0 |

| F 1000 | 10,0 | 4,5 +/– 0,8 | 1,0 |

| F 1200 | 7,0 | 3,0 +/– 0,5 | 1,0* |

| * at 80% | |||

Other grain sizes can be produced if required. | |||

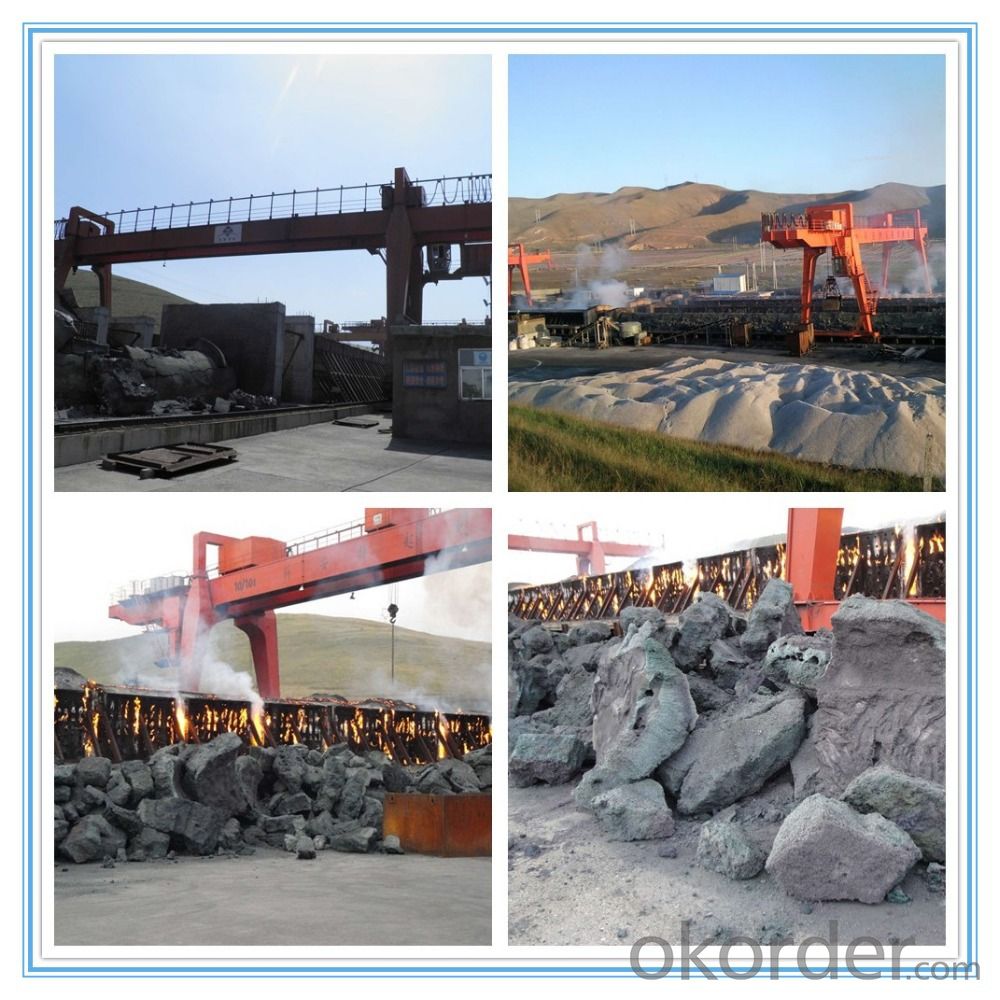

Factory and Package

Metallurgical Refinery

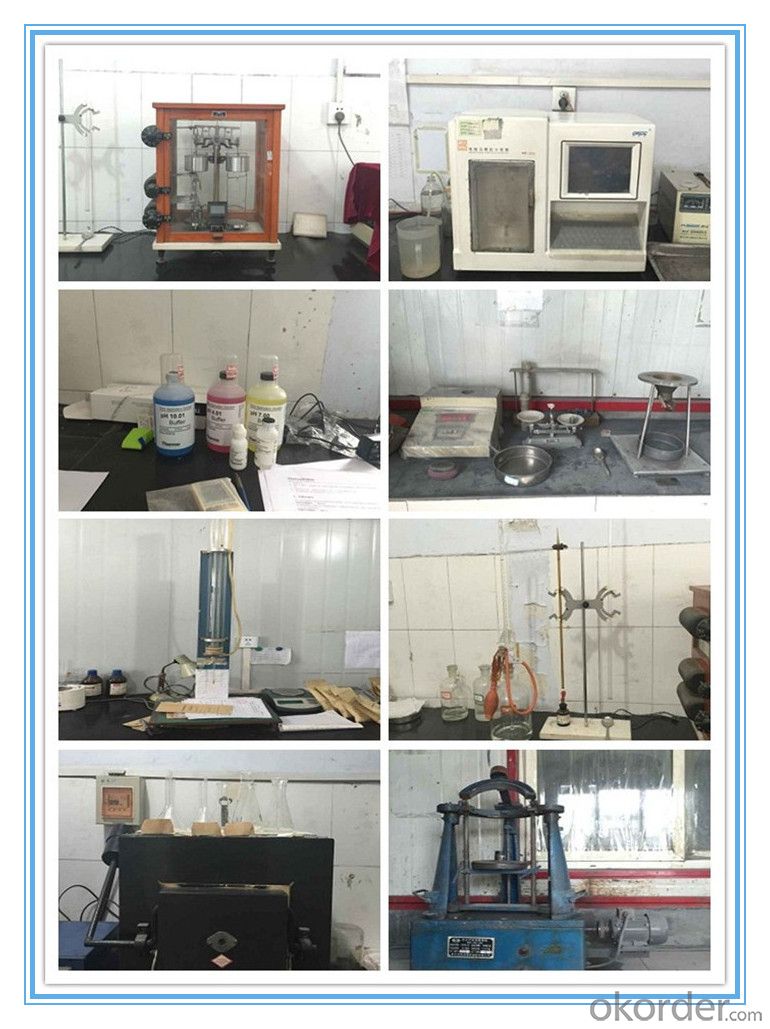

Grain Factory

Package

Equipment

FAQ

1 Your production capacity?

A: 3000 ton every month.

2 Will the free sample be provided for us?

A:We will provide free sample about 1 kg.

3 Did you have your own mancfactory?

A:Yes,We have.

- Q: What are the use of fire-resistant material and admixture?

- Generally speaking, there are several admixtures: 1. Water reducing agent. It can ensure basic refractory castable flow value and significantly reduce its water mixing amount sodium hexametaphosphate and sodium tripolyphosphate 2. Plasticizer. It can increase plastic refractory mixture and enhance the ability of bentonite clay mud material stress strain 3. Gelling agent. It can make the colloidal solution (or suspending liquid containing solid particles condensed gelling agent 4. Dispergator. It can turn condensation or reunion colloidal particles (particles) into sol or uniform dispersion suspended particles and make the thick colloid free stream sol said scattered coagulant peptizer 5. Coagulant. It can shorten the stereotypes refractories condense sclerosis NaOH Mars between aluminum hydroxide, etc. 6. Retarder. It can delay the stereotypes refractories condense sclerosis between citric acid tartaric acid, etc. 7. Delayed coagulant. It can make setting fire-resistant materials contain binder by set out the condensation hardening effect between calcium aluminate cement, etc. 8. Foaming agent. It can reduce the liquid surface of power to produce uniform stability as rosin soap bubble resin fat saponin and so on. 9. Antifoaming agent. It can make fast setting fire-resistant material mixing or shock in produce bubbles escape alcohol fatty acids, such as 10. Shrink agent can reduce or prevent the refractory materials used to produce contraction type heating said silicon powder stabilizer or volume expansion agent, etc. 11. Preservative. It can keep setting fire-resistant material stored on construction performance change or change oxalic acid citric acid, etc. 12. Inhibitors. It can inhibit stereotypes refractories ingredients contain iron or iron compounds and acidic reaction caused inflation to produce hydrogen bond CrO3 diacetone alcohol, etc. I hope it can help you.

- Q: What materials is silicious thermal insulation board made of?

- Refractories that contain more than 93% of the monox are acidic refractory materials which include ordinary silica brick, high-density and high-purity silica brick, silica brick that contains chromium, fused quartz products, unburned brick and siliceous ramming materials. It has good softening temperature under a fixed load and can resist corrosion of acid slag, but will have chemical reaction with alkaline slag. Silicious refractory of industrial value mainly is crystalline quartz, such as α and β quartz, tridymite and cristobalite.

- Q: What do we mean by saying that a ladle cover knots, elbow knots, blowpipe knots in refractory materials? What is the “knot”?

- Blowpipe is also the construction of unshaped refractory materials. Refractory material for ladle cover is light weight heat insulation refractory material. What you said that the construction of bend out refractory materials in some steel mills called "knot".

- Q: Which refractory quality inspection authority is good?

- Of course, it is Research Institue of Refractory Materials in Luoyang, Henan. In fact, what we want is accuracy and authority. Quality and inspection costs, which is more important?

- Q: Why do magnesium oxide refractory bricks can be made into refractories?

- Because the magnesium oxide, commonly known as magnesia, which is a basic oxide, with the common property of alkali oxides and belongs to the cementitious material . It is white or light yellow powder, odorless, tasteless, non-toxic and a typical of alkaline earth metal oxide, whose chemical formula is MgO. It is white powder, with melting point of 2852 ℃, boiling point of 3600 ℃ and relative density of 3.58 (25 ℃). The magnesium oxide that is soluble in acid and ammonium hydroxide solution has high insulation properity. After high temperature of above 1000 ℃ burning, it will transform into crystals, and when rising above 1500 ℃ , it will turn into dead-burned magnesium oxide (also known as the magnesia) or sintered magnesia. So the performance of magnesium oxide refractory bricks is good, and the fire resistance of it is very strong.

- Q: What high-molecular polymers can be used as fire-resistant material binder?

- Organic silicon

- Q: How long is the fire-resistant time of fireproof wooden door?

- The fire-resistant time of fireproof wooden door is about 1 hour. Fireproof wooden door refers to the door whose door frames, skeleton of the door leaf, door panels are made of timber or timber work and fire endurance reaches the provisions of "GB50045-95 design of tall buildings for fire protection". Fireproof door is one of devices for fire?prevention and separation of the building, generally used on the firewall, entrance and exit between stairs pipe shaft opening, which plays an important role in the reduction of fire losses.

- Q: Is aluminium oxide refractory material?

- Calcination aluminium oxide is refractory material of fine performance made from pure aluminium oxide through high-temperature calcination. It can be made into coarse-grained material, fine-grained material, fine powder and micro powder, which can be made into pure jade burnt products. For example, corundum brick, lightweight corundum bricks. It can also be made into a variety of unburning products together with other materials, such as carbonaceous materials. For example, aluminum carbon and aluminium zirconium carbonaceous materials. As for the production of unshaped refractory material, there are more species. It can be corundum, rubing grain, corundum spinel and can also be added into other materials to improve specific performance. It isn't limited to high-alumina castable refractory and it can be castable refractory, ramming?mass, impressionable plastic material, gunning mix and refractory mortar.

- Q: Can polystyrene foam color steel plate be used as decorative fireproofing material ?

- No, only non-combustible product can prevent fire. Most polystyrene foam boards are flammable which cannot prevent fire. Polyphenyl can only retard flame, highest fire?retardant fire?rating being B1 level. Under the same conditions, fireproof performance of polystyrene foam board will be better because most extruded sheets are made by recycling materials and contain much more impurities which will affect flame resisting property. The second reason is that high temperature in extruded sheet manufacturing technique will decompose part of flame retardants. For B1 level extruded sheet, it is difficult to reach 30 burning oxygen index, while for B2 level, it is hard to reach 32. So polyphenyl board is safer.

Send your message to us

Raw Materials for Refractory:Black Silicon Carbide for Abrasives and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords