Race Car Body Aluminum Sheets - 1100 1050 2024 3003 5052 6061 6082 7021 Alloy Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

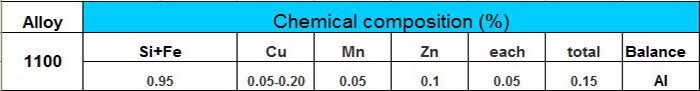

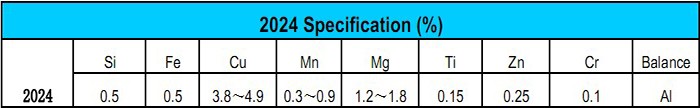

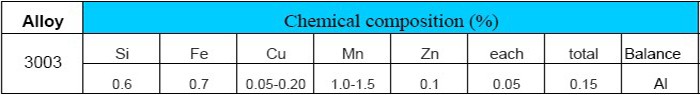

1.Alloy: 1100 1050 2024 2017 3003 5052 6061 6063 7075 7021 etc

2.Temper:O H112 H12 H14 H16 T3 T4 T6 T651 etc

3.Dimension based on customer requirements

4.Good quality choose us

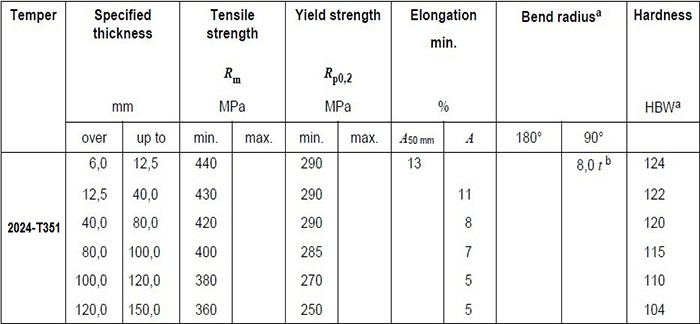

Chemical Composition:

Technical Specification:

Packaging & Delivery

| Packaging Details: | Wooden Pallet, Wooden Case, As Customzed, etc. |

| Delivery Detail: | 15 to 25 days depends on actual order |

Our Services

1) Reply within 12 hours

2) Free samples provided

3) On-site production following-up

4) Loading inspection with container fixing

5)Third party inspection at your request

Company Information

Advanced equipment and strict management both contribute to the excellent quality of products. Our main products are all kinds of cold rolling and hot rolling aluminum sheet, coil, checkered plate, embossed plate, aluminum foil, aluminum disc, aluminum profile, painted aluminum sheet and coil. Our products have various size choices with thickness from 0.008mm to 350mm, width from 200mm to 2300mm and length below 12m. Our products are sold to all over the world, including South America, North America, Europe, Middle-East, South-East Asia, Africa etc and used in various fields such as construction, decoration, automobile, electronic, machinery, boat construction, aeronautics&astronautics, cookware, packing etc.

Adhering to the principle of “ Surviving with quality and developing with credibility”, CNBM hopes to work with all customers for a better future.

FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 5 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4) Why YONGHONG?

With us, you get most competitive price, guranteened quality with assured delivery time and after sales service

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Can the aluminum sheets be used for manufacturing power transmission lines?

- Yes, aluminum sheets can be used for manufacturing power transmission lines. Aluminum has several properties that make it suitable for this purpose. First, aluminum is a lightweight material, which makes it easier to handle and transport compared to other metals like copper. This can help reduce installation costs and make the power transmission lines more efficient. Second, aluminum has good electrical conductivity, although it is not as conductive as copper. However, due to its lighter weight, aluminum can still achieve similar electrical performance as copper while using less material. This can result in cost savings and lower energy losses in the transmission lines. Furthermore, aluminum has excellent corrosion resistance, which is crucial for power transmission lines that are often exposed to various weather conditions and environmental factors. Aluminum can withstand harsh conditions and maintain its structural integrity over time, ensuring the reliability and longevity of the power transmission infrastructure. In conclusion, aluminum sheets can indeed be used for manufacturing power transmission lines due to their lightweight nature, good electrical conductivity, and excellent corrosion resistance.

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- Yes, 101 aluminum sheets have specific fire resistance properties. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which means it can withstand high temperatures before it starts to melt. Additionally, aluminum has a low combustion point, which means it does not readily catch fire. In case of a fire, aluminum sheets act as a barrier, preventing the spread of flames. Moreover, when aluminum does burn, it forms a protective oxide layer on its surface, which further inhibits the progress of the fire. However, it is important to note that while aluminum has fire-resistant properties, it is not completely fireproof and can still be damaged or deformed by intense heat.

- Q: Can aluminum sheets be used in the automotive industry?

- Aluminum sheets indeed find application in the automotive sector. Being a lightweight and sturdy material, aluminum offers several advantages when it comes to manufacturing automobiles. Car bodies, hoods, doors, and other structural components are commonly produced using aluminum. This helps in reducing the weight of the vehicle, resulting in improved fuel efficiency and enhanced performance. Furthermore, aluminum exhibits remarkable resistance to corrosion, making it ideal for vehicles that face harsh weather conditions. Moreover, aluminum sheets are easily formed, welded, and joined, which adds to their versatility and suitability for various automotive purposes. Consequently, the automotive industry widely embraces the utilization of aluminum sheets due to their numerous benefits.

- Q: Can aluminum sheet be used for electrical wiring?

- Electrical wiring cannot utilize aluminum sheet, as it is primarily employed for structural and decorative purposes owing to its lightweight nature and ability to resist corrosion. On the other hand, aluminum wire, specially designed for electrical applications, can be employed for electrical wiring due to its distinct characteristics. In the past, aluminum wire was frequently employed, but concerns regarding its conductivity, durability, and potential fire hazards have led to its replacement by copper wire in residential and commercial electrical installations. Copper wire is favored for its exceptional conductivity and reduced likelihood of loose connections or overheating.

- Q: What are the advantages of using 101 aluminum sheets over other materials?

- One advantage of using 101 aluminum sheets is their high strength-to-weight ratio, making them lightweight yet durable. Additionally, aluminum is highly resistant to corrosion, making it suitable for outdoor applications without the need for additional protective coatings. Aluminum sheets are also easy to work with due to their malleability, allowing for various forming and fabrication processes. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: What specific coatings or treatments are required for aluminum sheets to enhance their properties or protect them?

- <p>Special coatings or treatments for aluminum sheets may be needed depending on the application. Anodizing is a common treatment that enhances corrosion resistance and wear. For aesthetic purposes, aluminum can be painted or coated with a clear lacquer to maintain its appearance. Protective coatings like powder coating or electroplating can be used to improve durability and resistance to environmental factors. In certain industrial applications, aluminum sheets may be treated with specific coatings to enhance thermal or electrical conductivity. The choice of coating or treatment depends on the specific requirements of the project, such as resistance to weather, chemicals, or mechanical stress.</p>

- Q: How do you prevent discoloration of aluminum sheets?

- To prevent discoloration of aluminum sheets, there are a few steps you can take. Firstly, it is important to clean the aluminum sheets regularly to remove any dirt or debris that could potentially cause discoloration. Use a mild detergent or a specialized aluminum cleaner and a soft cloth or sponge to gently scrub the surface. Avoid using abrasive cleaners or scrubbing pads as they can scratch the surface and make it more prone to discoloration. Secondly, make sure to thoroughly rinse the sheets after cleaning to remove any residue from the cleaning products. Residual chemicals can react with the aluminum and cause discoloration over time. Another preventive measure is to apply a protective coating or sealant on the aluminum sheets. This can help to create a barrier between the metal and the surrounding environment, preventing oxidation and discoloration. There are various types of protective coatings available, such as clear lacquers or anodizing treatments, that can enhance the durability and appearance of the aluminum sheets. Additionally, it is important to store the aluminum sheets in a proper manner to minimize exposure to moisture, humidity, and extreme temperature fluctuations. Moisture can accelerate the oxidation process and lead to discoloration. Store the sheets in a dry and well-ventilated area, away from direct sunlight or sources of heat. Regular maintenance is crucial to prevent discoloration. Inspect the aluminum sheets periodically for any signs of discoloration or damage, and promptly address any issues that arise. By following these preventive measures, you can maintain the aesthetic appeal and longevity of aluminum sheets.

- Q: does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

- Q: Is it possible for an individual to install their own aluminum sheet roofing?

- <p>Yes, you can install your own aluminum sheets roof, but it requires some skills and knowledge. You'll need to measure and cut the sheets accurately, secure them properly, and ensure watertight installation. It's advisable to have experience in roofing or construction, or to follow detailed instructions and safety precautions. For complex roofs or if you're unsure, hiring a professional is recommended to avoid damage or injury.</p>

Send your message to us

Race Car Body Aluminum Sheets - 1100 1050 2024 3003 5052 6061 6082 7021 Alloy Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords