024 Aluminum Trailer Siding Sheets - Aluminum Sheet 1060/3003/5052/6061/6063/7075

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Common Aluminum Sheet Coil

1. Place of Origin: ZheJiang, China (Mainland)

2. Model Number: 1050/1060/3003/3004/5052/8011

3. Thickness: 0.20-20.0 mm

4. Width: 1000-1700 mm

Packaging & Delivery

1. Coating: Wooden Pallet for Exporting

2. Delivery Detail: 25-30 Days

Specifications

Aluminum Sheet

1. Alloy: 3003A1050/1060/3003/3004/5052/8011

3. Thickness (mm): 0.20-20.0

4. Width (mm): 1000 mm to 170 0mm, Customer Specific Width

5. Finish: Mill, Customer Specific Finish

Our main products are aluminum alloy thick sheet

PS/CTP plate (1050)

anodic oxidation / 3003/5052 (1060/1070)

automotive aluminum alloy (5754/6111/6061)

soldering material (3003/4004)

IT used materials (3003/5052)

the LED base material, material can (3004/3104)

the tank cover and TAB (5052/5182)

aluminous model with substrate (1100)

medicinal foil (8011)

household foil aluminum foil (1235) (8011)

Car Industry:

Alloy: 5182、5083、5754、5052、5042、6061、6063、6082

Feature: nice appearance, good formability, high safety factor, paint hardening effect is significant.

Product Name | Alloy | Usage |

Automotive sheet: interior panels | 1*** 3*** 5*** | Cars, automotive structural components |

Automotive sheet: structure | 1*** 3*** 5*** 6*** | Cars, automotive structural components |

Automotive sheet: housing,auto body | 3*** 5*** 6*** | Cars, automotive structural components |

Transportation Industry

Alloy: 1060、3003、5052、5754、5083、4104、6061、6016, etc..

Feature: High strength, excellent resistance to stress corrosion and welding performance.

Product Name | Alloy | Usage |

Coal car sheet | 1*** 3*** 5*** | Transporter application areas: coal car plate |

Thick aluminum sheet | 1*** 3*** 5*** 6*** | In industrial applications, such as aluminum cans tanker, auto body outer and inner plates |

Brazing sheet | 4*** composite panels | Oxygen equipment and automotive radiator |

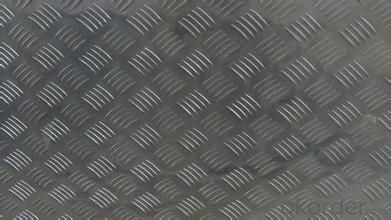

Embossed aluminum sheet | 1*** 3*** 5*** | Nonslip floor decoration; nonslip floor; inside the vehicle with the non-slip floor |

- Q: What is the best way to paint over aluminium siding? Should it be primed? What type of prime should be used? What type of paint should be used on this surface? What brush or roller should be used to apply the paint?

- while I've never done it, my brother in law painted their aluminum siding. He used paint he bought at sears- go to a paint store, one that only sells paint and pick their brains. He power washed the house, primed it and used a sprayer to apply both the paint and the primer....the house looks like they replaced the siding.

- Q: im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- they can be made outta plastic or wood, prboably something else..but i can't thnk of it. ive had a plastic 1 and it still worked great..even though it was the ch eapest grinder in the store. so..personal preference really. gl

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Due to their lightweight, durability, and versatility, aluminum sheets are commonly used in architectural design and construction for applications such as cladding, roofing, facades, and decorative elements. They offer various finishes, patterns, and colors, making them suitable for enhancing the aesthetic appeal of both interior and exterior spaces. Additionally, aluminum sheets are resistant to corrosion and require minimal maintenance, making them a popular choice for decorative and architectural purposes.

- Q: Can aluminum sheets be used in the aerospace industry?

- Yes, aluminum sheets are commonly used in the aerospace industry due to their lightweight, high strength, and corrosion resistance properties. They are used in the construction of aircraft structures, such as fuselages, wings, and interior components, to ensure optimal performance and fuel efficiency.

- Q: What are the common sizes of aluminum sheet?

- Some common sizes of aluminum sheet include 4x8 feet (48x96 inches), 4x10 feet (48x120 inches), and 5x10 feet (60x120 inches).

- Q: What specific requirements or considerations are necessary when using aluminum sheets in marine environments?

- <p>In marine environments, aluminum sheets must meet specific requirements to ensure durability and resistance to corrosion. These include using high-grade aluminum alloys, such as 5083 or 5086, known for their excellent resistance to saltwater corrosion. Protective coatings like anodizing or applying marine-grade paints can further enhance corrosion resistance. Additionally, the aluminum sheets should be designed to withstand the harsh conditions of marine environments, including high humidity, UV radiation, and mechanical stress. Regular maintenance and inspection are also crucial to prevent corrosion and ensure the longevity of aluminum structures in marine settings.</p>

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: Can aluminum sheets be anodized for improved corrosion resistance?

- Aluminum sheets have the capability to undergo anodization in order to enhance their resistance to corrosion. Anodizing, an electrochemical process, is utilized to generate a protective oxide layer on the surface of the aluminum. This oxide layer effectively shields the aluminum from corrosion and deterioration. Throughout the anodization process, the aluminum sheet is immersed in an electrolyte bath and an electric current is applied. As a result, the aluminum bonds with oxygen ions, forming a dense and substantial aluminum oxide layer on the surface. This oxide layer acts as a barrier, preventing moisture and other harmful substances from reaching the underlying metal. Anodized aluminum sheets possess improved strength, extended lifespan, and heightened resistance to corrosion, making them highly suitable for a wide range of applications such as architecture, automotive manufacturing, and aerospace industries. Furthermore, anodized aluminum sheets can be dyed in numerous colors, offering not only enhanced corrosion resistance but also aesthetic appeal.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Yes, aluminum sheets can be used for heat exchanger fins. Aluminum is a popular choice for heat exchanger fins due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. Aluminum fins allow for efficient heat transfer between the fluid and the surrounding environment. Additionally, aluminum sheets are easily formed into various fin shapes and sizes, providing flexibility in design. Overall, aluminum sheets are a suitable and commonly used material for heat exchanger fins.

- Q: How do I calculate the weight of aluminum sheet? What is the density?

- First calculate the density of each aluminum plate, then calculate the volume, then the density is good, the volume is the weight

Send your message to us

024 Aluminum Trailer Siding Sheets - Aluminum Sheet 1060/3003/5052/6061/6063/7075

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords