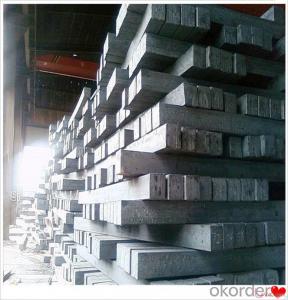

Q195, Q235, Q275, JIS Ss400, 3sp, 4sp Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Gbq195, Q235, Q275, JIS Ss400, 3sp, 4sp Steel Billets

1.Executive Standard:GB,ASTM,DIN,JIS,BS

2.Product:Q195,Q235,Q275,SS400,S185,S235JR Steel Billets

3.Process: Hot rolled

4.Application:These products are widely used in all kinds of architecture and engineering structure, such as the beam, Bridges, transmission tower, hoisting, ship,industrial furnace, container frame and warehouse and Other fields.

5.Surface Condition: Black or as required

6.MOQ:1000MT

7.Chemical Composition:

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 1000mt.

4. Q: What's the delivery time?

A: It will take about 30-45 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: What are the different coil leveling machine configurations used for steel coils?

- There are several different coil leveling machine configurations that are commonly used for steel coils. These configurations vary based on the specific requirements of the steel coils being processed. One common configuration is the four-high leveling machine. This machine consists of four leveling rolls arranged in a stack. The steel coil passes through these rolls, which apply pressure to flatten and level the material. The four-high configuration is often used for thicker and heavier steel coils, as it provides a higher level of pressure and control during the leveling process. Another configuration is the six-high leveling machine. This machine has six leveling rolls arranged in two stacks of three rolls each. The steel coil passes through the first stack, where the initial leveling is performed, and then through the second stack for further refinement. The six-high configuration is often used for thinner steel coils, as it allows for a more precise and gentle leveling process. In addition to these configurations, there are also combination leveling machines available. These machines combine leveling with other processes, such as slitting or shearing, to provide a more comprehensive solution for steel coil processing. Combination machines are often used in applications where multiple steps are required to achieve the desired final product. Overall, the choice of coil leveling machine configuration depends on factors such as the thickness and weight of the steel coil, as well as the desired level of precision and efficiency. Manufacturers and processors must carefully evaluate their specific needs and select the appropriate configuration to ensure optimal results in the steel coil leveling process.

- Q: Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- Steel okorder /

- Q: What are the limitations of using steel coils in certain applications?

- There are several limitations to consider when using steel coils in certain applications. Firstly, steel coils can be heavy and bulky, which makes them less suitable for applications where reducing weight is crucial. Industries like aerospace or automotive, which prioritize lightweight materials for fuel efficiency and performance improvement, may not find steel coils to be the best choice. Secondly, steel coils are prone to corrosion, especially in environments with high moisture or exposure to chemicals. This limitation can restrict their use in applications where corrosion resistance is crucial, such as marine or coastal structures. To mitigate this limitation, additional protective coatings or regular maintenance may be necessary, resulting in increased costs and maintenance efforts. Furthermore, steel coils may lack the necessary flexibility or malleability required for certain applications. Industries like construction or manufacturing, which often require materials to be easily shaped or bent into specific forms, may find steel coils inadequate in terms of flexibility. This limitation can create difficulties in achieving desired designs or may necessitate additional processing steps to mold the steel coils into the desired shape. Lastly, steel coils may have limitations in terms of temperature resistance. In high-temperature applications like furnaces or power generation, steel coils may experience thermal expansion or deformation, compromising their structural integrity. In such cases, alternative materials with higher temperature resistance, such as refractory metals or ceramics, may be more appropriate. Overall, while steel coils are versatile and widely used materials, their limitations in weight, corrosion resistance, flexibility, and temperature resistance can restrict their use in certain applications. It is important to consider these limitations and assess the specific requirements of each application when selecting materials to ensure optimal performance and durability.

- Q: Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- Just know the type of steel ,its density. Density gives you weight per unit of volume. For example: The density of mild steel is approximately 7.85 g/cm^3 (0.284 lb/in^3) From above , you can say that 1 cm^3 of volume of mild steel have 7.85 gram weight.

- Q: I have one and need info about it??....It has a wooden case around the steel necks.and 20 strings,Twin Tens.

- well, it was made sometime before 1981, because that's when Fender quit making 10 string steel guitars. Without any more information than what you've given me, it could be the Pedal 2000, the PS210, or the Artist Dual 10. Fender made steel guitars from the 1950s through 1981, so it could be from any time in there. I hope you have the pedals with it. The 10-string and dual 10-string models were quite expensive in their day. Unfortunately, if you're thinking of reselling it, you're probably not going to get a lot of money for it unless you find a pedal steel player, and like I said, having all the pedals is very important in that case. Anyway, hope this helped. Good luck. If I were you I'd learn to play it. Pedal steel players are always in demand.

- Q: How are steel coils transported?

- Steel coils are typically transported using specialized flatbed trucks or railcars. The coils are carefully loaded onto these vehicles and secured using straps or chains to prevent any movement during transit. In some cases, shipping containers are also used to transport steel coils via cargo ships.

- Q: please i need your help in answering this question manufacturing process of steel containers and 20 references

- There are many types of steel containers and many different mnfg processes. There are also thousands of different steel alloys. Steel is used for canned food, compressed air cyclinders, hydraulic pressure vessels, electrical boxes, and many other containers. Steel containers are made out of sheet metal by soldering, brazing, spot welding, seam welding, riveting, bolting, screwing, etc. Heavier wall containers are fabricated of plate steel. Some steel containers are made by deforming the steel by extruding, forging, spin forming, drawing, ironing, etc. Some steel containers are made by machining. You should be able to find plenty of references if you search for these terms. good luck

- Q: is it much difference between 1095 and 1080,,,1065,,,1060 or even 1045 steel?please help and thanks!

- The guy below me obviously has no idea WTF he's talking about. It does NOT have anything to do with the edge angle at which the blade is sharpened. It does NOT have to do with heat treating. Both of these things are important, but they won't determine the type of steel. I'll try to help. 1095 is one of the best performing steels, against carbon steel or stainless steel, in the world. It's incredibly hard, holds its edge well and comes to a beautiful edge when sharpened correctly. As you know though, carbon steels need to be properly maintained to avoid rust/corrosion. Out of the steels you listed I'll give a brief summary of each steel... -1095 (Great all around steel, but is brittle by comparison to the others. This doesn't mean it will chip easily, but the other steels can take more of a beating. That being said, this is going to take a nicer edge, and hold it longer.) -1080 (A little bit more flexible and less liable to chip than 1095. A good compromise between edge retention/quality and ruggedness. -1065 (Commonly used in machetes and other heavy duty bush tools. Takes a decent utility edge and is highly unlikely to chip) -1060 1045 (Both extremely flexible and soft in comparison to 1095. Unlikely to chip, but it takes a crude edge. This edge will cut, but not like 1095 will.) Go with 1095. My favorite knife I own is in 1095 and serves me well everytime I head off into the woods. Keep some Rem-Oil on that bad boy though.

- Q: I would like to know the process of making steel from the mining of ore to the final product. Can anybody offer some help? Either where to look, or the process itself. I would like to have included the different options with which to make steel. Through scrap metal, or iron ore briquettes etc... Thanks.

- Adding 6% carbon to molten iron makes steel.

Send your message to us

Q195, Q235, Q275, JIS Ss400, 3sp, 4sp Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords