Gbq195, Q235, Q275, JIS Ss400, 3sp, 4sp Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1.Executive Standard:GB,ASTM,DIN,JIS,BS

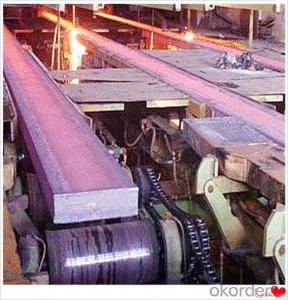

2.Product:Q195,Q235,Q275,SS400,S185,S235JR Steel Billets

3.Process: Hot rolled

4.Application:These products are widely used in all kinds of architecture and engineering structure, such as the beam, Bridges, transmission tower, hoisting, ship,industrial furnace, container frame and warehouse and Other fields.

5.Surface Condition: Black or as required

6.MOQ:1000MT

7.Chemical Composition:

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

8. FAQ

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 25mt.

4. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: How do steel products contribute to the renewable energy sector?

- Steel products contribute to the renewable energy sector in various ways. Firstly, steel is used in the manufacturing of wind turbines, providing structural integrity and support for the blades and towers. Additionally, steel is used in the construction of solar panels, ensuring durability and longevity. Furthermore, steel is utilized in the transmission and distribution infrastructure for renewable energy, such as power lines and grid systems. Overall, steel products play a vital role in the development, installation, and maintenance of renewable energy technologies, enabling the sector to flourish and reduce reliance on fossil fuels.

- Q: How is steel used in the production of amusement park rides?

- Steel is commonly used in the production of amusement park rides due to its strength, durability, and ability to withstand heavy loads and extreme weather conditions. It is used to construct the framework, supports, and tracks of roller coasters and other thrill rides, ensuring safety and stability for riders. Steel is also used in the fabrication of various components, such as brackets, bolts, and hinges, that are essential for the smooth operation and structural integrity of amusement park rides.

- Q: What are the properties and characteristics of different steel products?

- Different steel products have various properties and characteristics depending on their composition and manufacturing processes. Some common properties of steel products include high strength, durability, and resistance to corrosion. Additionally, steel products can be categorized based on their specific characteristics such as hardness, ductility, and toughness. Moreover, different steel products can have specific applications due to their unique properties, such as structural steel for construction, stainless steel for food processing and medical equipment, or tool steel for manufacturing tools and machinery.

- Q: How are steel gratings used in the construction of industrial platforms?

- Steel gratings are commonly used in the construction of industrial platforms to provide a strong and durable flooring solution. These gratings are designed to support heavy loads and provide a safe walking surface for workers. They are often used in areas where there is a need for ventilation, drainage, or visibility. Overall, steel gratings play a crucial role in enhancing the stability, safety, and functionality of industrial platforms.

- Q: How do steel products contribute to the aerospace industry?

- Steel products contribute to the aerospace industry in multiple ways. Firstly, steel is used in the construction of aircraft frames and structural components, providing strength, durability, and resistance to high temperatures. Secondly, steel is vital in the manufacturing of jet engines, where it is used for turbine blades, casings, and exhaust systems due to its high heat resistance and excellent mechanical properties. Additionally, steel is utilized in aerospace fasteners, landing gear, and hydraulic systems, ensuring the overall safety and reliability of aircraft. Overall, steel products play a crucial role in enhancing the performance, efficiency, and safety of aerospace vehicles.

- Q: What are the common uses of steel in the mining industry?

- Steel is commonly used in the mining industry for various purposes such as constructing mining equipment, building infrastructure like mine shafts and tunnels, creating support structures for mines, and manufacturing machinery and tools used in mining operations.

- Q: How is steel wire used in the manufacturing of springs?

- Steel wire is commonly used in the manufacturing of springs due to its high tensile strength and flexibility. It is typically coiled or bent into the desired shape, allowing it to store and release energy when pressure is applied. The steel wire's resilience and durability make it an ideal material for creating springs that are used in various applications, such as automotive suspensions, mattresses, and mechanical devices.

- Q: What are the different types of steel profiles used in machinery frames?

- There are several types of steel profiles commonly used in machinery frames. Some of the most common ones include I-beams, H-beams, and C-channels. These profiles are chosen based on their strength, rigidity, and ability to support heavy loads. Each profile has its own unique properties and is selected based on the specific requirements of the machinery frame.

- Q: How is steel tubing manufactured?

- Steel tubing is manufactured through a process called tube making, which involves several steps. First, a flat strip of steel is passed through a series of rollers to shape it into a cylindrical form. Then, the edges of the strip are fused together using either electric resistance welding or high-frequency induction welding. After welding, the tube is cooled and straightened, followed by further processing such as sizing, cutting, and shaping. Finally, the tubing may undergo additional treatments like heat treatment or coating before being ready for use in various applications.

- Q: What are the uses of steel gratings?

- Steel gratings have various uses in different industries. They are commonly used as flooring in industrial settings, such as factories and warehouses, due to their durability and strength. They provide a safe and stable surface for workers to walk on and allow for ventilation and drainage. Steel gratings are also used in construction projects as scaffolding platforms or stair treads. Additionally, they find applications in industries like mining, oil and gas, transportation, and agriculture, where they are used as catwalks, platforms, fences, and shelving.

Send your message to us

Gbq195, Q235, Q275, JIS Ss400, 3sp, 4sp Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords