PVC Waterproofing Sheets in 1.2mm with Fabric Back

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Sheets in 1.2mm with Fabric Back

Product Description of PVC Waterproofing Sheets in 1.2mm with Fabric Back:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproofing Sheets in 1.2mm with Fabric Back:

1. Excellent anti-aging property.

2. Puncture- resistant.

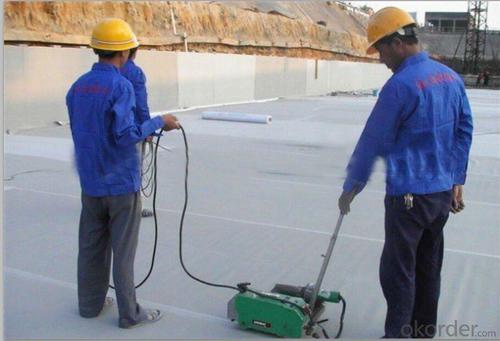

3. Welding construction,

4. High tensile strength, good elongation, good dimensional stability.

5. Good plasticity.

6. It has self-extinguishing from fire property.

7. Materials surface is smooth, fast color, stain resistance.

8. More wide, Wastage become less when being used.

Classification of PVC Waterproofing Sheets in 1.2mm with Fabric Back:

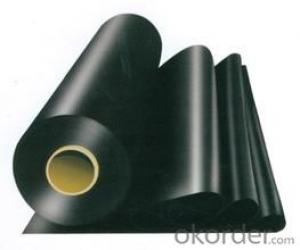

1. N: Homogeneous PVC membrane

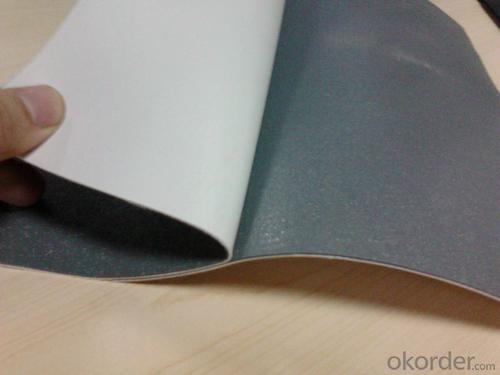

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Sheets in 1.2mm with Fabric Back:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Sheets in 1.2mm with Fabric Back:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Sheets in 1.2mm with Fabric Back:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

Images of PVC Waterproofing Sheets in 1.2mm with Fabric Back:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for a balcony?

- A balcony can indeed use a waterproofing membrane. Its purpose is to safeguard against water infiltration and shield surfaces from moisture-related harm. Since balconies are exposed to the elements and vulnerable to water damage, it is crucial to apply a waterproofing membrane in order to prolong their lifespan and maintain their structural soundness. By applying the membrane to the surface of the balcony, a barrier is created that effectively prevents water from seeping through cracks or joints. Consequently, this safeguards against water-related issues such as leaks, mold, and deterioration of structural components. It is of utmost importance to choose a high-quality waterproofing membrane that is specifically suitable for outdoor use and capable of withstanding exposure to UV rays, temperature fluctuations, and foot traffic. Consulting a professional contractor is recommended to ensure proper installation and to select the most appropriate waterproofing system tailored to the specific needs of your balcony.

- Q: Can a waterproofing membrane be applied on any surface?

- When applying a waterproofing membrane, it is essential to take into account the unique characteristics and needs of each surface. Although many waterproofing membranes are versatile and can adhere to different materials, it is advisable to seek advice from a professional or the manufacturer to ensure compatibility and optimal performance. For concrete surfaces, waterproofing membranes are effective in preventing water penetration and safeguarding against moisture damage. These membranes are specifically designed to bond with concrete and create a barrier against water and vapor transmission. However, it is crucial to thoroughly prepare the concrete surface by cleaning it, fixing any cracks or imperfections, and ensuring a smooth and even substrate for the membrane to adhere to. Similarly, masonry surfaces such as brick or stone can benefit from the application of waterproofing membranes. These surfaces may require additional preparation, such as the removal of loose mortar or debris, and might benefit from using a primer to enhance adhesion. The porosity and texture of these surfaces may also influence the choice of waterproofing membrane. Wood surfaces, such as decks or balconies, can be protected against moisture damage and have their lifespan extended by applying a waterproofing membrane. However, it is important to select a membrane specifically designed for wood surfaces, as these materials require additional flexibility to accommodate the natural movement and expansion of wood. In conclusion, while waterproofing membranes can be used on a variety of surfaces, it is crucial to consider the specific characteristics and preparation requirements of each surface to achieve the best results. Seeking guidance from a professional or the manufacturer can help determine the most suitable membrane and application method for a particular surface.

- Q: Can waterproofing membranes be used on green roofs?

- Yes, waterproofing membranes can indeed be used on green roofs. In fact, they are an essential component of green roof systems. Green roofs are designed to have a layer of vegetation and growing medium on top of a waterproofing layer. This waterproofing layer prevents water from penetrating through the roof and causing damage to the building structure. Waterproofing membranes used on green roofs are specifically designed to withstand the unique challenges of such installations, including exposure to water, UV radiation, and root penetration. These membranes are typically made from durable materials such as PVC, TPO, or EPDM, which are known for their excellent waterproofing properties. Additionally, some waterproofing membranes used on green roofs may have additional features such as root resistance and UV stability, ensuring that the roof remains watertight and protected for an extended period of time. Overall, using waterproofing membranes on green roofs is crucial in creating a sustainable and long-lasting roofing system that provides both water protection and environmental benefits.

- Q: Are there any specific requirements for installing a waterproofing membrane?

- Yes, there are specific requirements for installing a waterproofing membrane. Some key requirements include ensuring a clean and dry surface, proper preparation of the substrate, correct application of the membrane according to manufacturer's instructions, and adequate curing time. Additionally, ensuring proper seam and joint treatments, as well as sufficient overlap and termination details, are essential for an effective waterproofing installation. It is crucial to follow the specific guidelines and recommendations provided by the manufacturer to ensure a successful and long-lasting waterproofing system.

- Q: How does a waterproofing membrane handle movement of a building due to settling or seismic activity?

- A waterproofing membrane is designed to accommodate the movement of a building caused by settling or seismic activity. It offers a flexible and elastic barrier that can stretch and contract with the building's movements, preventing any water penetration. When a building settles or experiences seismic activity, it can undergo significant structural movements. These movements can cause cracks, shifts, or changes in the building's foundation, walls, or floors. Without proper waterproofing, water can seep through these cracks or gaps, leading to water damage, mold growth, and structural deterioration. To address this, waterproofing membranes are typically made of materials that have excellent elongation and recovery properties. Elongation refers to the membrane's ability to stretch without tearing, while recovery refers to its ability to return to its original shape after being stretched. This flexibility allows the membrane to move with the building, rather than resisting or cracking under the stress. Moreover, waterproofing membranes are installed in a way that allows for horizontal and vertical movement. They are often applied in layers, with overlapping seams to create a continuous barrier. This layered approach accommodates any potential shifts or settlements in the building by allowing the membrane to move and adjust accordingly. In areas prone to seismic activity, additional measures may be taken to reinforce the waterproofing system. These can include the use of specialized membranes that have higher elongation and recovery properties or the incorporation of reinforcement elements such as fabric or mesh to enhance the membrane's ability to handle movement. In summary, a waterproofing membrane is specifically designed to handle the movement of a building caused by settling or seismic activity. Its flexibility, elongation, and recovery properties, along with proper installation techniques, allow it to accommodate the building's movements while maintaining a watertight barrier.

- Q: Can a waterproofing membrane be used for loading docks or ramps?

- Yes, a waterproofing membrane can be used for loading docks or ramps. A waterproofing membrane is designed to protect surfaces from water damage by creating a barrier that prevents water from seeping through. Loading docks and ramps are exposed to various weather conditions and can be prone to water infiltration, which can cause damage over time. Applying a waterproofing membrane to these surfaces can help to prevent water penetration, protecting the structure and increasing its lifespan. Additionally, a waterproofing membrane can also provide added benefits such as slip resistance, protecting against chemical spills, and reducing maintenance costs.

- Q: Can a waterproofing membrane be used on lead surfaces?

- Yes, a waterproofing membrane can be used on lead surfaces. Lead surfaces are often found in the roofing industry, and applying a waterproofing membrane can help protect against water damage and leaks. It is important to ensure that the waterproofing membrane is compatible with lead, as some membranes may react with or degrade the lead material. Additionally, proper surface preparation and installation techniques should be followed to ensure a secure and effective waterproofing solution. Consulting with a professional or manufacturer for specific product recommendations and installation guidelines is recommended.

- Q: Is a waterproofing membrane resistant to saltwater or other corrosive substances?

- Yes, a waterproofing membrane is typically resistant to saltwater and other corrosive substances. The membrane is designed to provide a protective barrier against moisture and chemicals, ensuring durability and preventing damage caused by corrosive elements.

- Q: Can a waterproofing membrane be used in laundry rooms?

- Yes, a waterproofing membrane can be used in laundry rooms. It is commonly used to protect against water damage and prevent leaks in areas where water is present, such as laundry rooms, bathrooms, and kitchens.

- Q: Can a waterproofing membrane withstand heavy rain or water pressure?

- Yes, a waterproofing membrane is designed to withstand heavy rain or water pressure. The purpose of a waterproofing membrane is to create a barrier that prevents water from penetrating through a structure or surface. These membranes are typically made with materials such as rubberized asphalt, PVC, or EPDM (ethylene propylene diene monomer), which are highly resistant to water and can effectively withstand heavy rain or water pressure. Additionally, these membranes are often reinforced with layers or fabrics to provide added strength and durability. Therefore, when properly installed and maintained, a waterproofing membrane can effectively withstand heavy rain or water pressure, providing reliable protection against water damage.

Send your message to us

PVC Waterproofing Sheets in 1.2mm with Fabric Back

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords