PVC Waterproof Membrane Manufacturer with ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, anti-oxygen, ultraviolet absorber and other auxiliaries.

2. Features

l Excellent aging resistance.

l Root resistant penetration, specially used on planting roof.

l Welding installation. Joints are solid and environment friendly, no pollution.

l High tensile strength, good elongation and dimensional stability.

3. Specification

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

If exposed | Exposed, Non-exposed |

Type | Homogeneous, Reinforced with fabric backing |

Color | White/Grey or customized |

4. Application

l All kinds of roofs, such as steel structure roof, planted roof etc.

l Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

l Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

5. Technical Data Sheet

PVC Waterproof Membrane | Standard: GB12952-2011 | ||||||

NO. | Item | Unit | Value | ||||

H | L | P | |||||

1 | Resin Thickness on Middle Mesh ≥ | mm | - | - | 0.4 | ||

2 | Tensile Properties | Max. Strength ≥ | N/cm | - | 120 | 250 | |

Tensile Strength ≥ | Mpa | 10.0 | - | - | |||

Elongation at Max. Strength ≥ | % | - | - | 15 | |||

% | 200 | 150 | - | ||||

3 | Dimensional Stability after Heat Treatment ≤ | % | 2.0 | 1.0 | 0.5 | ||

4 | Foldability at Low Temperature | -25℃ No cracks | |||||

5 | Watertightness | 0.3Mpa, 2h No penetration | |||||

6 | Resistance to Impact | 0.5kg*m, No penetration | |||||

7 | Resistance to Static Loading* | - | - | 20kgs No penetration | |||

8 | Joint Peel Strength≥ | N/mm | 4.0 or membrane broken | 3.0 | |||

9 | Right Angle Tearing Strength≥ | N/mm | 50 | - | - | ||

10 | Trapezoid Tearing Strength≥ | N | - | 150 | 250 | ||

11 | Water Absorption (70℃, 168h) | After immersing≤ | % | 4.0 | |||

After drying≥ | % | -0.40 | |||||

12 | Aging in Hot Weather (80℃) | Time | 672h | ||||

Appearance | No bubbles, cracks, layering, sticky, holes | ||||||

Max. Tensile Retention Rate ≥ | % | - | 85 | 85 | |||

Tensile Strength Retention Rate ≥ | % | 85 | - | - | |||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 80 | |||

Breaking elongation Retention rate≥ | % | 80 | 80 | - | |||

Low Temperature Flexibility | -20℃ No cracks | ||||||

13 | Chemical resistance

| Appearance | No bubbles, cracks, layering, sticky, holes | ||||

Max. Tensile Retention Rate ≥ | % | - | 85 | 85 | |||

Tensile Strength Retention Rate ≥ | % | 85 | - | - | |||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 80 | |||

Breaking elongation Retention rate | % | 80 | 80 | - | |||

Low Temperature Flexibility | -20℃ No cracks | ||||||

14 | Artificial aging* | Time | 1500h* | ||||

Appearance | No bubbles, cracks, layering, sticky, holes | ||||||

Max. Tensile Retention Rate ≥ | % | - | 85 | 85 | |||

Tensile Strength Retention Rate ≥ | % | 85 | - | - | |||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 80 | |||

Breaking elongation Retention rate | % | 80 | 80 | - | |||

Low Temperature Flexibility | -20℃ No cracks | ||||||

Remarks: *Resistance to static load is for PVC membranes used on roofing *The time of artificial aging of single-ply roofing membrane is 2500h. *Non-exposed membrane does not require determination of artificial aging. | |||||||

Welcome to discuss cooperation!

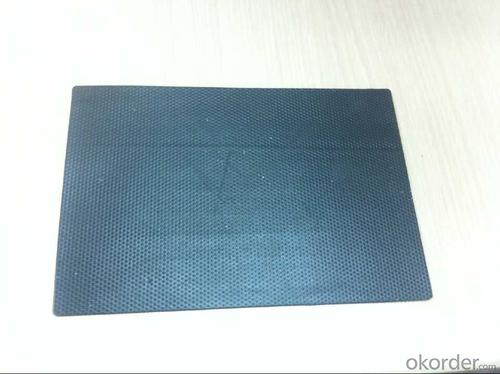

6. Image for EPDM Waterproof Membrane

- Q: Can a waterproofing membrane be used in mining or excavation projects?

- Yes, a waterproofing membrane can be used in mining or excavation projects. Waterproofing membranes are designed to prevent the ingress of water and other liquids, making them an ideal solution for areas that are prone to water intrusion, such as mines or excavations. These membranes are typically made from durable materials, such as rubber or bitumen, and are applied to the walls, floors, or roofs of these structures to create a watertight barrier. By using a waterproofing membrane, mining and excavation projects can minimize the risk of water damage, protect equipment and infrastructure, and ensure a safe working environment for workers.

- Q: Can a waterproofing membrane be installed on a sloping surface?

- Yes, a waterproofing membrane can be installed on a sloping surface. In fact, it is often necessary to install a waterproofing membrane on sloping surfaces to ensure proper water drainage and prevent water seepage.

- Q: Can a waterproofing membrane be used for underground parking garages?

- Yes, a waterproofing membrane can be used for underground parking garages. In fact, it is highly recommended to use a waterproofing membrane in these types of structures to prevent water infiltration and damage. Underground parking garages are prone to water seepage from the surrounding soil, and the constant exposure to moisture can lead to structural deterioration, corrosion of steel reinforcements, and the growth of mold and mildew. A waterproofing membrane acts as a barrier, preventing water from penetrating the walls and floors of the garage. It is applied to the exterior surfaces of the structure, providing a protective layer that keeps the interior dry and free from water-related issues. The membrane should be selected based on the specific requirements of the project, considering factors such as the type of construction materials, the groundwater conditions, and the anticipated level of water pressure. Additionally, proper installation techniques and regular maintenance are crucial to ensure the long-term effectiveness of the waterproofing system.

- Q: Can a waterproofing membrane be used for warehouses or storage facilities?

- Warehouses or storage facilities can utilize a waterproofing membrane. These membranes are specifically designed to safeguard structures against water damage by creating a barrier that prevents moisture infiltration. In warehouses and storage facilities, there are often large areas that are vulnerable to potential leaks or seepage, such as roofs, walls, and floors. By installing a waterproofing membrane, these structures can be effectively shielded from water intrusion, thereby preventing harm to stored goods and maintaining the facility's integrity. Waterproofing membranes come in various types, including bituminous, liquid-applied, or sheet membranes, providing flexibility in selecting the most appropriate option based on the specific requirements of the warehouse or storage facility. Furthermore, waterproofing membranes offer additional advantages such as thermal insulation and resistance to chemicals, further enhancing their value in ensuring the durability and functionality of warehouses or storage facilities.

- Q: Are waterproofing membranes resistant to soil chemicals?

- Yes, waterproofing membranes are typically resistant to soil chemicals. These membranes are designed to provide a barrier against water and moisture, and they are often made from materials that are resistant to various chemicals found in the soil. This resistance helps to protect the membrane from degradation or damage that could be caused by exposure to soil chemicals. Additionally, waterproofing membranes are often tested and certified to meet specific industry standards and regulations, which include resistance to soil chemicals. However, it is important to note that the level of resistance may vary depending on the specific type and quality of the waterproofing membrane used. Therefore, it is crucial to select the appropriate membrane that is specifically designed to withstand the soil conditions and chemicals present in the project area. Consulting with a professional or manufacturer can provide further guidance on the best waterproofing membrane for a specific application.

- Q: What is waterproofing membrane?

- According to the brand classification Construction industry waterproofing membrane mainly Dike waterproof membrane, DuPont waterproofing membrane, Sicon waterproofing membrane, which the first two participating GB chart set. According to its main waterproof composition material can be divided into asphalt waterproof material, high polymer modified waterproof membrane and synthetic polymer waterproofing membrane (SBC120 polyethylene polypropylene composite membrane) three categories. There are PVC, EVA, PE, ECB and other waterproofing membrane Asphalt waterproofing membrane is in the base tire (such as base paper, fibrous fabric) dip on asphalt, and then spread in the surface of powder or sheet of the isolation material made of curled sheet waterproof material.

- Q: What is the PEDM waterproofing membrane material?

- It is widely used at home and abroad high-grade waterproof material for roof, underground, subway, bridges and require a higher waterproofing works.

- Q: Can waterproofing membranes be used on wood surfaces?

- Yes, waterproofing membranes can be used on wood surfaces. Waterproofing membranes are versatile and can be applied to various materials, including wood. They provide a protective barrier that prevents water from penetrating the wood, helping to prolong its lifespan and prevent damage caused by moisture.

- Q: Can a waterproofing membrane reduce noise transmission?

- Yes, a waterproofing membrane can help reduce noise transmission. Waterproofing membranes are typically made of materials with good sound insulation properties, such as rubber or synthetic polymers. When applied to surfaces, they create a barrier that helps absorb or block sound waves, reducing the amount of noise that can pass through the structure. Additionally, waterproofing membranes can also help seal gaps and cracks in walls or floors, further reducing noise leakage. So, while the primary function of a waterproofing membrane is to prevent water infiltration, it can also have the secondary benefit of reducing noise transmission.

- Q: Can a waterproofing membrane be used on plaster surfaces?

- Yes, a waterproofing membrane can be used on plaster surfaces. Plaster is a porous material that can easily absorb water, making it susceptible to damage from moisture. Applying a waterproofing membrane on plaster surfaces helps to create a barrier that prevents water from penetrating the plaster, thus protecting it from moisture-related issues such as mold, mildew, and deterioration. It is important to ensure that the plaster surface is clean, dry, and free from any loose or flaking material before applying the waterproofing membrane. Additionally, proper surface preparation and application techniques should be followed to ensure the effectiveness and longevity of the waterproofing system.

Send your message to us

PVC Waterproof Membrane Manufacturer with ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords