PVC Wall Panel Hot Glossing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container m²

- Supply Capability:

- 80Containers/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

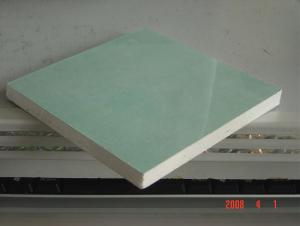

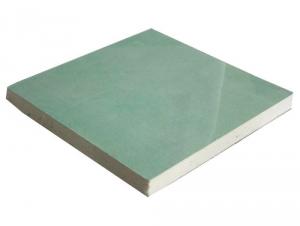

Description of Gypsum Board:

1.We have three kinds of gypsum board, regular gypsum board, fire-proof gypsum board and moisture resistant gypsum board. And our product are mainly used for Ceiling system, Partitio system, Dry lining system and we also provide its allied system such as: Channels, joint compound, joint tape, screws and so on.

2.Gypsum board edge:

Tapered edge (recessed edge) And Square edge (straight)

Raw Materials of Gypsum Board:

Using high purity gypsum powder as main material and mixed with fiber and highquality additive

SIZE: (mm)1200*2400 1220*2440 1200*3600 1220*3600 1200*2500 1220*2500

Thickness: ( mm) 6.4 to 16

Applications of Gypsum Board:

1: Ceiling system,

2: Partition system,

3: Dry lining system

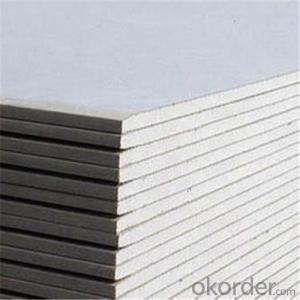

Package of Gypsum Board

1.Naked with bulk in container by hand

2.Load with pallet by forklift

Production Flow:

We have 5 production line for gypsum board, 60 containers can be produced per month.

We are focus on study new and green product for our customer, we are your best choice.

- Q: Will the decoration under the big brother Cut the ceiling gypsum board to pay attention to what? Little brother to do decoration apprentice very hard Master old to the hardest job I do easy to do with him Made a week apprentice really bitter A few days to cut the ceiling gypsum board get an exhaust fan is also estimated that I cut the cut Would you like to take any precautions?

- First of all, your mind to adjust, there is no difficulty can baffle you, give you painstakingly you see as your will temper Let you enhance patience, increase the sense of responsibility, to work hard, dry line of love and his party, you will get unexpected gains. Do a good job of interpersonal relationships, is a blessing, slowly you are used. You bring a wallpaper knife, pawl saw, petal screwdriver, if the gypsum board with joinery, it is necessary to bring hand saws and pliers.

- Q: i whant to know what the process is to measure up a job of a basic house for plasterboard off the plan. and how to order the right sized sheets for the job.thanx!

- Plasterboard/ sheetrock comes in 4x8 & 4x12 ft sheets 1/2 to 3/4 inch thick.. 4x12s are usually railroaded ( applied horizontally) but are heavy & harder to handle in small residential spaces. Also take into account doubling up if the plans call for fire rated walls or clgs in furnace enclosures or attached garage space. Measure each individual wall surface to the scale of the drawing or pick off written dimensions & divide by 4 if applying vertically in an area w/ an 8 ft clg. Eg a 12 x 16.room will need 14 sheets for walls & 6 sheets for clg. 1/2 thick or better for walls & 3/4 for clgs Wall length total ..12+12+16+16= 56 ft divided by 4= 14 Ceiling area .12x 16= 192 sq ft ( area of ech 4x8 =32sq ft) 192 divided by 32 = 6 In residential construction door & window openings are not figured in unless they are very wide & tall. Measuring too closely can cause you to run short esp if a wall dimensions run out greater than even multiples of 4 & you can consider anything over to be a full sheet & use the cutoff in another space. Your supplier can give est on taping compound , joint tape & fasteners based on your order. Wall & clg sq footage is also used to est paint . wallcovering & floor covering requirements Best regards

- Q: Mall of a boutique house, partition are separated by gypsum board, would like to set directly on the above article plus the kind of steel hanging clothes, ok "will not be broken ah.

- To be fixed in the fixed gypsum board in the wood or keel on the firm,

- Q: What is the aluminum plate? What place to use it, and what is different from the gypsum board

- Aluminum slab plate is the ceiling material, mainly used in the top of the kitchen, there are used in the balcony or other shapes, is the metal, there is a certain water resistance, so used in the kitchen, the current majority of the aluminum plate is a square, There are stripes, a lot of patterns, the color is also a lot, you can mix with the market, the integrated ceiling is the aluminum plate, as well ...

- Q: Do you use a gypsum board to make a wall that is neither strong nor clean?

- Gypsum board to do the wall is possible to facilitate the latex paint and wallpaper, a few specific practices are as follows: 1, light steel keel gypsum board wall, suitable for the general requirements of the wall is not high. 2, light steel keel double gypsum board partition, the stability of the better, you can install the door. 3, light steel keel double gypsum board sound-absorbing cotton partition, this soundproof requirements for the partition. 4, light steel keel single layer of nine plywood gypsum board wall, the wall can be painted.

- Q: it is always a dry wall

- Liquid Nails makes a specific drywall adhesive.... which should work...as long as you think you'll NEVER have to remove that drywall for any reason. If this is a below grade wall.... do yourself a favor....don't glue drywall to the brick.

- Q: down. The writing on the back says that i cannot plaster on the side that now faces the floor. What can i do. I have fitted recessed spotlights and now need to make good the surface, ie plaster ready for painting. Can i still do so after maybe pva'ing / bonding the surface?

- I agree with Woodtick. Use coarse thread drywall screws on the ceiling trusses/joists and rock to rock screws in the field. I hate hanging lids; no sense adding the weight and mess of liquid nails. You should be alright on the lights, the springs that hold the finish ring usually have a little play.

- Q: y good?

- The spray in foam sounds great,, BUT it's not cheap and here is the REAL PROBLEM. If your house ever gets a leak, the foam will not absorb the water, nor will the aluminum. If there is any wood in the walls, it will absorb the water. If the leak is not detected, the wood will eventually start to rot. If the wood is a structural member of your home,things will start to fall apart. This may take awhile, but it will show It's ugly head and by the time it does, it may be too late to save it.

- Q: I'm renovating a 110year old end terrace. Plaster is all off right back to brick and I'm re plastering myself when the time comes. I took a professional quote and the contractor said that for the external facing walls, because I've stripped it all back, I'd need to use insulated plasterboard to conform to building regs??? Is this true? If so what is the minimum standard?

- Only your local code enforcement officer can answer your question properly. Any other answer is just a guess.

- Q: It doesn't mention the length, but I need it to be at least 3 inches long. Would this one work?

- That one will do the trick if it is three inches long. For all intents and purposes, plasterboard and dry wall are the same thing. Remember, however, if the think you are sticking in is a screw that is 3/16ths, you don't want to use a 3/16 drill, use one smaller so the threads have something to grab.

1. Manufacturer Overview

| Location | Shangdong, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 30.00% Mid East 30.00% Africa 20.00% Southeast Asia 10.00% Domestic Market 5.00% South America 5.00% North America |

| Company Certifications | third-party verification service provider |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above3000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average; Low |

Send your message to us

PVC Wall Panel Hot Glossing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container m²

- Supply Capability:

- 80Containers/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches