PVC High Polymer Waterproofing Membrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

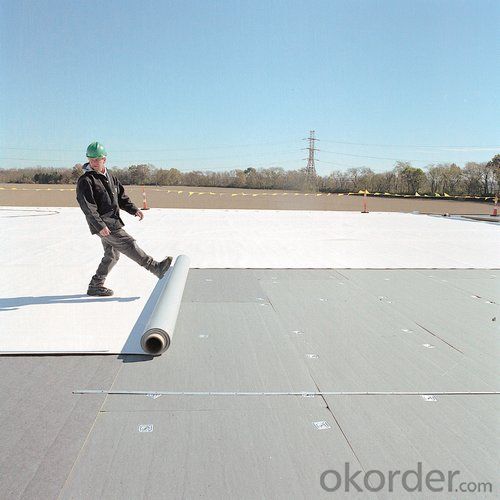

1.Introduction for PVC Waterproofing Membrane

The P series waterproofing membrane is a heat-weldable membrane produced with an integral polyester reinforcement for high strength,for use in a Magical Stone's solution system. Its excellent performance of resistance to plasticizer extraction and migration, extend the product's life and more friendly to environment.

2.Technical data of PVC Membrane

No. | Item | Index | ||||||

H | L | P | G | GL | ||||

1 | resin thickness over the fabric mm,≥ | — | 0.4 | |||||

2 | tensile strength | max tension (N/CM),≥ | — | 120 | 250 | 120 | ||

tensile strength/Mpa,≥ | 10 | — | — | 10 | — | |||

elongation at max tension/%,≥ | — | — | 15 | — | — | |||

break elongation/%,≥ | 200 | 150 | — | 200 | 100 | |||

3 | thermal size change/%,≤ | 2 | 1 | 0.5 | 0.1 | 0.1 | ||

4 | low temperature flexibility/℃ | —25 no crack | ||||||

5 | impermeability | 0.3MPa,2h impermeable | ||||||

6 | anti-impact | 0.5kg.impermeable | ||||||

7 | static load | 20kg impermeable | ||||||

8 | cut strength/(N/mm),≥ | |||||||

joint peeling strength/(N/mm),≥ | 4 | 3 | ||||||

9 | vertical tearing strength/(N/mm),≥ | 50 | — | — | 50 | — | ||

10 | trapezoid tearing strength/(N/mm),≥ | 150 | 250 | 220 | ||||

11 | water absorption(70℃,160h)% | after saturation≤ | 4 | |||||

after dry≤ | —0.4 | |||||||

12 | heating aging | hour/h | 672 | |||||

appearance | no bubble,crack,seperation | |||||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

13 | anti chemical property | appearance | no bubble,crack,seperation | |||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

14 | artificial | hour/h | 1500 | |||||

appearance | no bubble,crack,seperation | |||||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

3.Characteristic of PVC Membrane

1.Strong tensile strength, high elongation, can fit big deformation of substrates.

2.Excellent anti-extreme weather property, can adapt to various environment temperature difference.

3.Suitable for exposed projects with long lifetime and good anti-aging property.

4.Can be welded firmly and reliably.

5.Outstanding root penetration resistance, best choice for planted roofs.

6.Simple and fast construction without pollution.

7.Great plasticity and fast treatment with corners and details.

3.Applicable scope of PVC Membrane

PVC sheet forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway& tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

4. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes resistant to UV rays?

- Yes, waterproofing membranes are designed to be resistant to UV rays. UV rays from the sun can degrade and damage many materials over time, including certain types of waterproofing membranes. To prevent this, manufacturers often incorporate UV stabilizers into the membranes during the production process. These stabilizers help to protect the membrane from the harmful effects of UV rays, such as fading, cracking, and deterioration. Additionally, some waterproofing membranes may have an outer layer or coating that provides an extra layer of UV protection. However, it is important to note that the level of UV resistance can vary depending on the type and quality of the waterproofing membrane, so it is advisable to consult the manufacturer's specifications and recommendations for the specific product being used.

- Q: Are waterproofing membranes resistant to mold and mildew?

- Yes, waterproofing membranes are generally resistant to mold and mildew. These membranes are designed to create a barrier against moisture, preventing it from seeping into the structure and causing mold and mildew growth. Waterproofing membranes are often made from materials such as rubber, PVC, or bitumen, which are not conducive to mold and mildew growth. Additionally, these membranes are installed in a way that ensures proper drainage and ventilation, further reducing the chances of mold and mildew formation. However, it is important to note that while waterproofing membranes can greatly reduce the risk of mold and mildew, they are not foolproof. It is still essential to maintain proper ventilation and address any water leaks or damage promptly to prevent mold and mildew growth.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Yes, a waterproofing membrane can be used for underground bunkers. Waterproofing membranes are designed to create a barrier against moisture, preventing water penetration into structures. This makes them an effective solution for underground bunkers, which are susceptible to water infiltration due to their underground location. By applying a waterproofing membrane to the walls and floor of the bunker, it can help to prevent water seepage and keep the interior dry. This is crucial for the protection of any stored items or occupants within the bunker. Additionally, waterproofing membranes can also provide added benefits such as insulation and protection against radon gas. It is important to ensure that the chosen membrane is specifically designed for underground applications and can withstand the unique conditions and pressures associated with being underground.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Indeed, specific tools and equipment are indispensable when it comes to the installation of a waterproofing membrane. Some of the imperative tools and equipment that one must possess include: 1. Protective gear: To safeguard oneself from any detrimental chemicals or fumes, it is crucial to wear protective gear like gloves, goggles, and a face mask. 2. Cleaning equipment: Prior to the installation of the membrane, it is essential to have a clean and debris-free surface. Hence, one may require a broom, vacuum cleaner, or pressure washer to ensure thorough cleaning. 3. Waterproofing membrane: The appropriate type of membrane is contingent upon the project's requisites. It is vital to possess the right membrane material and sufficient coverage for a proper seal. 4. Primer: In certain cases, the utilization of a primer may be warranted to enhance adhesion between the surface and the membrane. The choice of primer is contingent upon the surface material and type of membrane being utilized. 5. Application tools: These tools are instrumental in the process of applying the membrane onto the surface. Brushes, rollers, or sprayers are some common application tools. The selection of tools is dependent on the type of membrane and the scale of the project. 6. Seam tape: If the waterproofing membrane necessitates seams, the presence of seam tape is vital to ensure an airtight seal at the joints. The tape must be compatible with the membrane material. 7. Adhesive or adhesive tape: Certain waterproofing membranes demand the utilization of adhesive for bonding them to the surface. Alternatively, adhesive tape can be employed for self-adhesive membranes. 8. Cutting tools: Based on the shape and size of the area to be waterproofed, one may require cutting tools such as utility knives or scissors to trim the membrane to the desired dimensions and shape. 9. Caulking gun: A caulking gun is an imperative tool for applying sealant or caulk to fill any gaps or cracks in the surface before the membrane installation. 10. Drying equipment: Following the installation of the membrane, a certain amount of time may be required for it to dry or cure. Depending on the specific membrane and environmental conditions, fans or dehumidifiers may be necessary to expedite the drying process. It is of utmost importance to refer to the manufacturer's guidelines or seek professional advice to ensure that all the necessary tools and equipment are available for a successful installation of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for loading docks or ramps?

- Yes, a waterproofing membrane can be used for loading docks or ramps. A waterproofing membrane is designed to protect surfaces from water damage by creating a barrier that prevents water from seeping through. Loading docks and ramps are exposed to various weather conditions and can be prone to water infiltration, which can cause damage over time. Applying a waterproofing membrane to these surfaces can help to prevent water penetration, protecting the structure and increasing its lifespan. Additionally, a waterproofing membrane can also provide added benefits such as slip resistance, protecting against chemical spills, and reducing maintenance costs.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Yes, a waterproofing membrane can be used on adobe block surfaces. Adobe blocks are made from a mixture of clay, sand, and straw, which can be susceptible to water damage. Applying a waterproofing membrane can help prevent water penetration and protect the adobe blocks from moisture-related issues such as cracking, erosion, or mold growth. It is important to ensure that the waterproofing membrane is compatible with adobe surfaces and follows the manufacturer's guidelines for application. Additionally, proper surface preparation and repair of any existing damage is crucial before applying the membrane to ensure its effectiveness.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Indeed, stormwater management systems can benefit from the application of waterproofing membranes. These membranes are frequently utilized to safeguard structures against water infiltration and potential water-related harm. In the case of stormwater management systems, which are designed to collect, retain, and efficiently handle rainwater runoff, waterproofing membranes can be employed to establish a completely watertight seal, thereby averting leaks and seepage. Stormwater management systems often incorporate various components, such as retention ponds, infiltration basins, or underground storage systems. These elements must be adequately sealed to ensure the proper containment and effective management of the collected stormwater. When properly installed, waterproofing membranes serve as an impermeable barrier, effectively preventing water from escaping or infiltrating the system. The utilization of waterproofing membranes on stormwater management systems offers numerous advantages. Firstly, it helps to maintain the system's integrity and functionality by preventing leaks or seepage that could compromise its performance. This ensures that the stormwater is efficiently captured and managed, minimizing the risk of flooding or erosion. Furthermore, waterproofing membranes can significantly prolong the lifespan of stormwater management systems by safeguarding them against water damage. Water infiltration can lead to structural degradation, corrosion, or the proliferation of mold and mildew, all of which weaken the system over time. By establishing a waterproof barrier, these membranes contribute to the preservation of the structural integrity of the components, thus increasing their longevity and reducing maintenance requirements. Moreover, the use of waterproofing membranes on stormwater management systems also contributes to environmental sustainability. By effectively containing and managing stormwater runoff, these systems aid in reducing water pollution and enhancing the quality of natural water bodies. Waterproofing membranes play a vital role in preventing stormwater from carrying pollutants, such as chemicals or sediment, into rivers, lakes, or oceans. In conclusion, waterproofing membranes can be effectively utilized on stormwater management systems to establish a watertight seal, prevent leaks, and protect the components from water damage. By providing an impermeable barrier, these membranes help to maintain the system's functionality and integrity, prolong its lifespan, and contribute to environmental sustainability by reducing water pollution.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces. Waterproofing membranes are designed to create a barrier against moisture and prevent water penetration, regardless of whether it is applied to the inside or outside of a structure.

- Q: How much does a waterproofing membrane cost?

- The cost of a waterproofing membrane can vary depending on several factors. The type of membrane, the size of the area to be waterproofed, and the complexity of the installation can all affect the price. On average, the cost of a waterproofing membrane can range from $1 to $5 per square foot. However, this is just a rough estimate and the actual cost can be higher or lower based on the aforementioned factors. For example, a basic sheet membrane made of PVC or EPDM might be on the lower end of the price range, while a liquid-applied membrane or a more advanced system like a bentonite clay membrane can be on the higher end. Additionally, the size of the area to be waterproofed will impact the cost. Larger areas will require more materials, labor, and time, which can increase the overall price. Complexity of the installation is another factor to consider. If the area is hard to access or requires extensive preparation work, such as removing existing materials or repairing cracks, the cost may be higher. It is recommended to consult with a professional waterproofing contractor who can assess your specific needs, provide an accurate estimate, and recommend the most suitable waterproofing membrane for your project.

- Q: Can a waterproofing membrane be used in basements?

- Yes, a waterproofing membrane can definitely be used in basements. In fact, it is highly recommended to use a waterproofing membrane in basements to protect against moisture intrusion and potential water damage. A waterproofing membrane is a thin layer of material that is applied to the external walls or floors of a basement to prevent water from seeping through. It acts as a barrier, effectively preventing water from entering the basement and keeping it dry. This is particularly important in areas where the water table is high, or in regions prone to heavy rainfall or flooding. By installing a waterproofing membrane, homeowners can greatly reduce the risk of water damage, mold growth, and other issues associated with excess moisture in the basement. It is important to note that proper installation and maintenance of the waterproofing membrane is crucial to ensure its effectiveness and longevity.

Send your message to us

PVC High Polymer Waterproofing Membrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords