PVC Coated Fiberglass Fabric for Electric Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Fabric with Silicone Coated for Electric Insulation

Fiberglass Fabric Description

Silicone coated fiberglass fabric is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and is coated with organic silicone rubber.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

It has been widely used in construction, electric insulation,

chemical industry, pipeline ductile conjunction, large generating

Corrosion proofing field, machinery, metallurgy, sealing and so on.

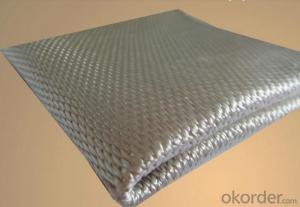

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: Is fiberglass fabric suitable for use in medical dressings?

- Fiberglass fabric is indeed appropriate for use in medical dressings. It possesses numerous characteristics that render it perfect for this purpose. Firstly, its high durability and strength offer exceptional support and protection to wounds or injuries. Additionally, it resists tears and punctures, ensuring the dressing remains intact even when in motion. Furthermore, fiberglass fabric is lightweight and breathable, allowing the passage of air and moisture, which aids in healing and prevents infections. Moreover, it is non-absorbent, meaning it does not retain moisture, thereby preventing the dressing from becoming damp or uncomfortable. Furthermore, fiberglass fabric is hypoallergenic, reducing the likelihood of allergic reactions in patients with sensitive skin. Overall, these qualities make fiberglass fabric an appropriate option for medical dressings as it provides the necessary protection and support while ensuring comfort and promoting healing.

- Q: Can fiberglass fabric be used for filtration in water treatment plants?

- Yes, fiberglass fabric can be used for filtration in water treatment plants. It is commonly used as a filtration medium due to its high strength, durability, and resistance to chemicals. Additionally, fiberglass fabric has excellent filtration properties, effectively removing impurities and particles from water, making it an ideal choice for water treatment applications.

- Q: How does fiberglass fabric perform in vibration isolation applications?

- The excellent performance of fiberglass fabric in vibration isolation applications is well-known. This material possesses inherent properties, including high tensile strength, flexibility, and low thermal conductivity, which make it perfect for effectively isolating vibrations. When exposed to vibrations, fiberglass fabric absorbs and dampens the resulting energy, thereby reducing the transmission of vibrations from one component to another. This ability to absorb vibrations is crucial in industries such as automotive, aerospace, and construction, where minimizing vibrations is vital for optimal performance and safety. Additionally, the high tensile strength of fiberglass fabric ensures that it can withstand the forces and stresses associated with vibrations without tearing or breaking. This strength is important for maintaining the fabric's integrity and effectiveness as a vibration isolator since any damage to the fabric could compromise its performance. Furthermore, the flexibility of fiberglass fabric allows it to conform to various shapes and surfaces, ensuring a secure and snug fit in vibration isolation applications. This flexibility enables the fabric to effectively isolate vibrations across a wide range of frequencies and amplitudes, making it a versatile solution for different vibration control needs. Lastly, the low thermal conductivity of fiberglass fabric is advantageous in vibration isolation applications where temperature differences exist. By minimizing heat transfer, the fabric helps maintain the stability and performance of isolated components, especially in environments with extreme temperatures. In conclusion, fiberglass fabric is highly effective in vibration isolation applications due to its ability to absorb and dampen vibrations, high tensile strength, flexibility, and low thermal conductivity. Its effectiveness, versatility, and durability make it the preferred choice for industries that require efficient vibration control.

- Q: What's the difference between glass fiber tape and fiberglass tape?

- Glass fiber belt is the base material, glass fiber cloth, without glue. Fiberglass is glass fiber. Glass fiber tape is called fiberglass cloth tape, a glass fiber tape, with aluminum film outside

- Q: Can fiberglass fabrics be used for insulation in electrical systems?

- Fiberglass fabrics are capable of being used for insulation in electrical systems. Due to its exceptional thermal and electrical insulation properties, fiberglass is a widely utilized material for insulation. It possesses non-conductive characteristics, signifying its incapability to conduct electricity. This quality renders it perfect for incorporation in electrical systems necessitating insulation to avoid the leakage of electrical current or short circuits. Moreover, fiberglass fabrics exhibit remarkable resistance to high temperatures, which renders them suitable for utilization in electrical systems that generate heat. The fabric form of fiberglass facilitates effortless installation and wrapping around electrical components, thereby furnishing a protective barrier against electrical shocks and preventing the transfer of heat. To summarize, fiberglass fabrics represent a dependable and efficient option for insulation in electrical systems.

- Q: How does fiberglass fabric perform in high-humidity environments?

- Fiberglass fabric boasts exceptional performance in environments with high humidity. Its non-absorbent properties ensure it remains impervious to moisture and unaffected by water vapor in the air. As a result, even in high-humidity conditions, fiberglass fabric maintains its structural integrity, strength, and dimensional stability. Unlike certain materials that may warp, shrink, or become brittle in humid conditions, fiberglass fabric remains unaffected. Moreover, the non-porous nature of fiberglass fabric hinders the growth of mold, mildew, and other fungi that thrive in moist surroundings. This renders fiberglass fabric an excellent choice for various applications, including boat building, outdoor furniture, and construction projects in high-humidity areas. Overall, fiberglass fabric's resistance to moisture and its ability to withstand high-humidity environments establish it as a reliable and durable material in such conditions.

- Q: Can fiberglass fabric be used for making sports equipment?

- Yes, fiberglass fabric can be used for making sports equipment. Fiberglass is a versatile material that offers a range of benefits, such as being lightweight, strong, and durable. These qualities make it ideal for sports equipment that requires high-performance characteristics, such as surfboards, skis, and hockey sticks. Fiberglass fabric can be used to reinforce the structure of these items, providing added strength and rigidity while still maintaining a lightweight design. Additionally, fiberglass fabric can be easily molded into various shapes, allowing for customization and enhancing the performance of sports equipment. Overall, fiberglass fabric is a popular choice in the sports industry due to its versatility, strength, and ability to enhance the performance of sports equipment.

- Q: What are the different printing options available for fiberglass fabric?

- Fiberglass fabric offers several printing options, each with its own advantages and applications. One option is screen printing, a versatile method that creates vibrant and detailed designs. Ink is pushed through a mesh screen onto the fabric, resulting in a durable and long-lasting print. Screen printing is suitable for both small and large print runs and can accommodate a wide range of designs and patterns. Another option is digital printing, which uses inkjet printers to directly print designs onto the fabric. This method produces high-resolution prints with intricate details, making it ideal for complex and multicolored designs. Digital printing also allows for more customization and is well-suited for smaller quantities. Sublimation printing is a process that involves transferring ink onto the fabric through a heat press. The ink is first printed onto transfer paper and then heat-pressed onto the fabric, resulting in vibrant and permanent prints. Sublimation printing offers excellent color reproduction and is often used for customized or personalized designs. Heat transfer printing is similar to sublimation printing but utilizes pre-printed designs on transfer paper or vinyl. These pre-printed designs are then heat-pressed onto the fabric. Heat transfer printing is commonly used for designs that require specific colors or effects that cannot be achieved through other methods. Lastly, rotary printing is a continuous process where the fabric is passed between a rotating cylinder and a stationary screen. This method is suitable for high-volume production and produces fast printing speeds and consistent quality. Rotary printing is often used for large-scale projects and can create intricate patterns and designs. When choosing a printing option for fiberglass fabric, factors such as design complexity, quantity, budget, and desired end result should be considered. Each method has its own strengths and limitations, so it is important to select the most suitable option for a specific project.

- Q: What fiber fabric can be replaced by fiberglass instead of itchy?

- At present, the main production of glass magnesium plate is glass fiber cloth, but fiberglass cloth has many kinds of quality specifications, mainly divided into high alkali cloth, medium alkali cloth and alkali free cloth, and no alkali cloth, also called white gold cloth.

- Q: Can fiberglass fabric be used for reinforcement in sporting goods?

- Yes, fiberglass fabric can be used for reinforcement in sporting goods. Fiberglass fabric is known for its high strength-to-weight ratio, making it an ideal choice for reinforcing various sporting goods such as surfboards, kayaks, canoes, skis, and even hockey sticks. The fiberglass fabric is typically used in conjunction with epoxy resin to create a strong and durable composite material. The fabric is impregnated with resin and then layered onto the desired area, providing additional strength and stiffness to the sporting goods. This reinforcement helps to improve the overall performance and longevity of the product. Additionally, fiberglass fabric is corrosion-resistant, lightweight, and has excellent impact resistance, making it a popular choice for reinforcing sporting goods.

Send your message to us

PVC Coated Fiberglass Fabric for Electric Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords