Sun Roof PVC Ceiling - High Quality Building Material Hot Stamping for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1) Fast and easy to install/clean/maitain

2) Without gap when PVC panel concatenated

3) High intensity, corrode-resisting, aging-resisting

4) Due to PVC panel's high chemical stability,our panels can be used more than 10 years

5) Prevent fire,water,antibiotic.

6) Harmless to human being and eco-friendly

7) For Ceiling and Wall decoration

8) Accessories(corners) accompany perfectly

9) Serial number of different specifications

10)Water resistant/ Moisture Resistant

11)Does not melt if harmed by fire, only crumbles

12)100% recyclable

13)Only for interior usage.

Product Advantages:

Description of product

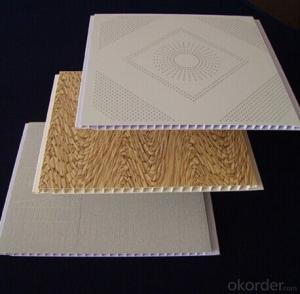

•Product name: PVC panel, PVC ceiling panel , PVC wall panel , PVC decorative panel , PVC decorative sheet , PVC board .

•Raw materials: PVC resin and calcium carbonate and other chemical.

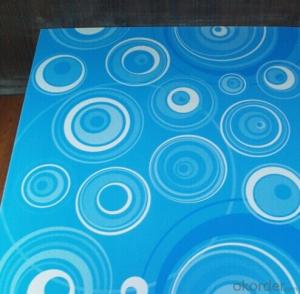

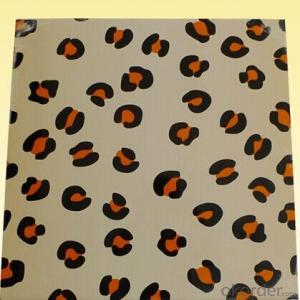

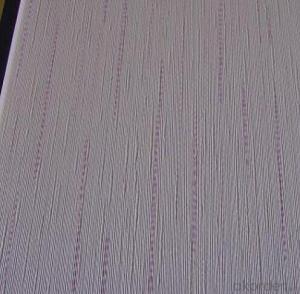

•Surface treatment: Normal printing , transfer printing (hot stamping), laminated , high glossy , Pearl

•PVC content: 40% , 45% , 50% ,60% etc .

•Shape:Flat , groove, cambered surface

•Color design :Marble , wooden , and other more than 2000 designs .

Main Product Features:

• Fireproof : Self-fire extinguishing, non-flammable , fire and inflaming retardant.

• Waterproof (dampproof): Resistance to weather/ special chemicals; Waterproof / Washable.

• Rustproof (resist erosion) : It is impenetrable by insects or termites, and won' t rot or rust.

• Heatproof : Good high temperature impact performance .

• High intensity : The excellent rigid and superior impacted surface is without any peeling.

• Anti aging : Good aging resistance , durable in all mechanical characteristics .

• Quality : Hard quality, high intensity and sheen , fadeless , environmental friendly .

• Design : The variety of colors and patterns .Natural wood (marble) grain: showing authentic wood (marble) structure and artistic sense.

• Easy setting : Light in weight , the simple and fast installation can save a lot of time and manpower cost.

• Other : Easy to be cut, drilled, nailed, sawed, and riveted. DIY is all right ;

Quick maintenance and no need of painting ;

Good resistance fixations .

Product Specifications:

Images:

- Q: Can PVC be used for automatic painting?

- First, PVC can be used automatic painting, PVC sheet surface can be painted, but must be on the surface of the sheet after the hair (with sandpaper to play again) in order to make the film better "adhesion" in the plate surface, And it is best to use anti-ultraviolet paint. Second, if you need pvc board paint, it is best to find professionals to complete. According to the plate production quality, and cost integrated: 1. Suitable for painting of the plate, solid wood, blockboard, high-quality multi-layer plywood, aluminum-plastic plate; 2. Suitable for cold paste PVC are: medium and high density board, particleboard, multi-layer board, woodworking board; 3. Suitable for hot-melamine are: MDF, high-grade multi-layer plywood, high-grade blockboard; 4. Suitable for the film: the ordinary multi-layer board, MDF, particleboard; 5. Suitable for imitation paper: ordinary solid wood, smooth multi-layer board, blockboard; 6. posted fire board are: MDF, particleboard and so on.

- Q: We installed sheets of red colored pvc sheeting under our upper deck to provide dry area below. It's spring I noticed a big area which has lots of splotches of dried gray stuff which looks like cement. Only thing I can think of is that we have a fire pit nearby outside the deck - but not sure how or what caused the splotches. I've tried a brush with soapy water, and tried Goof Off, then using a metal scraper which kind of works but leaves small scratches and WILL take FOREVER. Everything I've looked up says to use muriatic acid in water but I can't because it would drip down onto me. ANY BETTER IDEAS?

- Do not use GOOF OFF! Do not use muriatic acid either. You need to find out what the splotches are first. You say it looks like cement but why? Did you have any concrete work or brick pointing work or any type of cement work done to your house? If so if it was done by a contractor he is responsible not you. Any type of cement would wipe off of pvc sheets easily with a wet rag unless you wait to long after. GOOF OFF would ruin the pvc sheets if its the solvent based strong smell type. Cement splotches only appear after a sloppy contractor or sloppy home owner did cement work around the sheets but you didn't specify??

- Q: Looking at my exposed ceiling in the basement, I see two copper pipes coming out of the water heater, one marked in blue (assuming cold) and one in red (hot). These each split between supplying the upstairs and downstairs.After the split, there are galvanized steel pipes. I get great water pressure downstairs in the utility sink and clothes washer.Upstairs, pressure to the dishwasher, kitchen sink, and bathroom shower is terrible. It takes about 10 full seconds to fill a pint of water in the kitchen. You can imagine how long it takes to get a sink full of soapy water.Showers are annoying too with lack of pressure. I'm thinking I'll bring a plumber in to replace the piping to the upstairs. With a very amateur eye, I see about 10-15 total feet that'd need replacing.Is replacing it the answer? Or might there be something that could be locally repaired?Any estimates on cost for this?

- if the pipes are in good working order than i wouldnt bother replacing them. the problem is the water pressure is not good enought to push the water up at an increased speed. you will need to instal a water pump to increase water pressure, these arent very expensive look between ?100 to ?200 for a decent one, then say 4 hours of plumbers labour costs at roughlt ?80-?100. the pump will need an electrical feed so the parts for that and electricians labour costs. be careful though as higher water pressure may bring out leeks that u didnt know were there as older pipes sometimes cnt stand the new high pressure.

- Q: Chevrolet board and wood-plastic plate difference

- Chevrolet board, also known as PVC foam board, the main material for the PVC, PVC is made through the extrusion after extrusion molding equipment. In order to increase its performance often add antioxidants, flame retardants and so on. PVC wood-plastic plate, the main material for the PVC and wood flour, and PVC foam board production process is basically the same, but in the production process to control the degree of foam, and fully mixed with wood flour. In order to increase its performance, also need to add antioxidants, flame retardants and so on. The difference between the two, mainly reflected in the production of different raw materials. But all have a nail, can be riveting, drillable, can be sawed similar to the characteristics of wood.

- Q: Will the production of PVC gray pipe is about 40 meters is normal, after the pipe whitening, from the fish scale, reduce the speed and a little better. What is the reason

- Production process parameters have not changed the formula or mixed the problem

- Q: What is PVC material?

- Polyvinyl chloride And polyvinyl chloride

- Q: What is the proportion of PVC board? Thank you!

- According to the different weight of the process will be different, such as the foam process will be the point of the extrusion process will focus on the floor, but as the words of the floor than other wood ah tile ah what is much lighter

- Q: My house decoration, cupboard to buy the PVC board, but the wood workers said that the board can not grasp the nails, can not be used! The The But since the market so much to sell PVC cabinet board must have used for this board of hardware, which experts advise, very anxious to throw these boards is really sin ah

- Oh, cabinets with PVC board is generally made of MDF substrate. Understand the concept of PVC board? In fact, any plate through the PVC film vacuum plastic processing, it has a variety of color patterns only, if the substrate is not good, really does not take, so there is no PVC special hardware argument. Now how to solve these problems? First of all to clarify the specifications of the plate, in general, do the case of the cabinet can be used gluing practice, of course, do not recommend to do this cabinet, as to do the door, as long as not too heavy (since grasp the nail will not be heavy Where the general damping door hinge or can be installed on the fear of fixed can not open a reaming, this is called carpentry to deal with is. Finally, the cabinet, in addition to the door outside the door if not moisture board, are very top use, PVC board for the door to do a lot of cabinet doors, but the cabinet is generally visible in the original cabinet side of a piece of sheet together, or simply use PVC board, Not to use it to do the cabinet said.

- Q: What are the disadvantages of using PVC pipe cast-in concrete for house water supply line against G.I?

- pvc won't last this is best

Send your message to us

Sun Roof PVC Ceiling - High Quality Building Material Hot Stamping for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords