Modern And Minimalism PVC Ceiling Designs For Bedroom

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

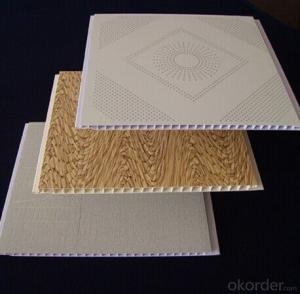

PVC ceiling designs, PVC laminated mgo ceiling

pvc laminated ceiling board

pvc mgo ceiling panel

pvc ceiling designs for living room

also named: PVC mgo ceiling, Polyvinyl Chloride membrane covered ceiling tiles, clean ceiling tiles, fireproof ceiling tiles etc.

Brief Introduction:

Wellyoung Clean Ceilings is used high quality magnesium cement as its substrate material.The surface is laminated with PVC membrane( short for Polyvinyl Chloride membrane), and the backside is pasted with strengthening aluminum foil as the reinforced material. The surface is light texture and waterproof, colors and patterns can be customized, which can enrich the top space.

Composition of Wellyoung Clean Ceilings:

Back material :superior aluminium foil

Base board: MgO board

Surface material :laminated PVC or PVC membrane

Advantages of PVC ceiling

Compare between Wellyoung PVC mgo ceiling & PVC gypsum ceiling

1. Fireproof

2. Waterproof

3. No dust and eco-friendly

4. Resist Deformation and Durability

5. Thinner and Lightweight

6. Stonger strength. 5mm or 6mm thickness Wellyoung PVC mgo ceiling is stronger than the traditional 7mm or 8mm PVC gypsum ceiling.

3.Image

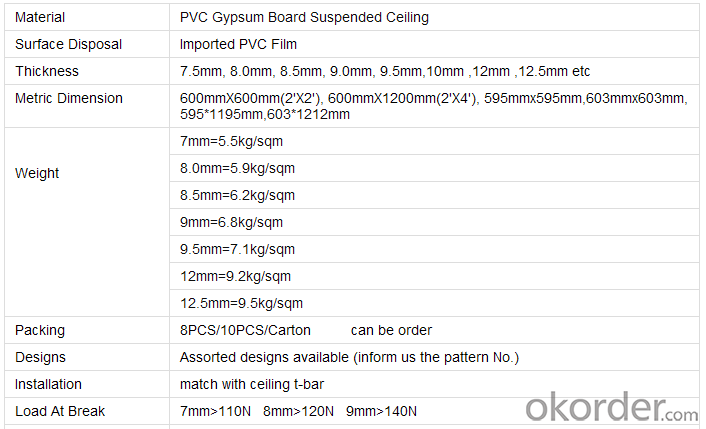

4.Detailed Specification

5.FAQ

1.Avoid sink and sag resistance

The high-quality magnesia gel base plate has the most stabilization. The common ceilings often absorb water and sink, but our ceilings can make sure the excellence quality long-term. It has superior resistance to sagging in high humidity conditions up to, but not including, standing water and outdoor applications.

2.Fire resistant and flame retardant

Measured by authoritative organization, the basic material is fireproof material for A grade. The panel will not burn or produce smog, and safety of life and property is guaranteed.

3.No dust

The components of this ceiling are so compact that there is little fiber dust left in the room. This ceiling could be used in high clean places, such as dust-free room.

4.Damp resistant and heat insulation

It has been tested that the basic material would never deformed or swelled when it is soaked in water. It also can maintain its property stably in the wet circumstance. In the back side, Wellyoung ceilings are pasted with aluminum foils which can radiate heat from top and play the function of heat insulation

5.Anti Mold/Mildew & bacteria

Inorganic substrate is inherently resistant to the growth of mold, mildew, and bacteria.

6. Waterproof and washable

This product can prevent from acid, alkali, insect and rot. It is easy to clean and will not sag from the effects of humidity

7.Durablity and Recyclable

The high quality coat and film could keep the nice and neatness effect and reduce the replacement cost. For the surface is pasted with calendered film, this product can be re-used after washing.

8.Environmental protection and Healthy

Without containing asbestos, formaldehyde, benzene and other substances which are harmful compositions, and have not been harmful in radiation, Wellyoung ceiling represents the new-type environmental protection materials.

- Q:Pvc transparent plate and the difference between acrylic

- Differences between PVC transparent and acrylic (PMMA) boards: The main difference is: Transparency and environmental protection, acrylic (PMMA) environmental protection is better than PVC, some manufacturers of PVC may be added in its formula inside the plasticizer (plasticizer), plasticizer choice is not good, then Harmful to the human body; Transparency: Acrylic (PMMA) transparency is better. The other is the price, PVC raw materials cheap, acrylic (PMMA) raw materials expensive.

- Q:What is the ignition of PVC?

- Generally about 256 ℃, the special temperature of 800 ℃.

- Q:PVC wood plate for the decoration of the store facade can be used?

- Is it the door of the store? Or is your store's sample? If it is the shop seems wrong. The sun will be discoloration, muster, shedding possible

- Q:Want to use the PVC board to do the model, you can color it? Gouache paint, paint can you?

- PVC board can be colored. PVC board from PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. PVC board is a vacuum plastic film, used for various types of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q:Flammability of Polyvinyl Chloride Plastics

- PVC combustion performance is not good, from the fire that is off, the flame was yellow, the bottom was green, white smoke, are flame retardant plastic; burning, irritating hydrogen chloride odor release, softening when burning.

- Q:PVC board and EVA board What is the difference, which is good flexibility

- PVC is a polymer that uses a chlorine atom to replace one of the hydrogen atoms in polyethylene. PVC is the most important feature of flame retardant, it is widely used in fire protection applications. But PVC in the combustion process will release hydrochloric acid and other toxic gases. ? EVA: ethylene-vinyl acetate copolymer is low foaming polyethylene foam plastic. Is a new type of environmentally friendly plastic packaging materials, with good cushioning, seismic, heat insulation, moisture, chemical corrosion, etc., with non-toxic, non-absorbent. Has a good anti-vibration: resilience and high tension, high toughness, With good shock / cushioning performance

- Q:Stainless steel and pvc board bonding what adhesive

- How big is the adhesive? What are the requirements? I have a high temperature, waterproof seal the structure of plastic, suitable for sticky metal, plastic, glass, etc.

- Q:What is the difference between an integrated ceiling and a PVC ceiling?

- Integrated ceiling: HUV metal plate and the combination of electrical appliances. Sub-board module, heating module, lighting module, ventilation module. With the installation is simple, flexible layout, easy maintenance, a bathroom, kitchen ceiling of the mainstream. Today, with the growing development of the ceiling industry, balcony ceiling, restaurant ceiling, living room ceiling, aisle and so on are gradually becoming the mainstream of home improvement. In order to change the monotonous lack of ceiling color, integrated art ceilings are becoming the market trendy. PVC gusset ceiling: the PVC resin as the base material, adding a certain amount of anti-aging agent, modifier and other additives, by mixing, rolling, vacuum blister and other technology made. This PVC gusset ceiling is particularly suitable for kitchen, bathroom ceiling decoration, with a light weight, moisture, heat insulation, not easy to burn, no dust, easy to clean, can be painted, easy to install, low prices. PVC buckle ceiling pattern more varieties, to choose from the varieties are: milky white, beige, lake blue, etc .; patterns are: Epiphyllum, flat peach, Xiong Zhu, Yunlong, grid flowers, parquet and so on. May require the production or distribution unit to produce its inspection report, and should pay special attention to whether the oxygen index is qualified, it must be greater than 30, is conducive to fire. And then according to the installation of the place and personal hobbies and environmental coordination and other factors, to select their own room decorated with decorative patterns.

- Q:MY girlfriend is using a 10' piece of 4 PVC to make a cat tree. About half way up, we put a wye joint in to make a shelf. The post will be fixed to the floor and ceiling. The problem is that the post flexes back and forth at the wye joint. I used silicone, but it didn't help the movement. Is there some kind of expanding caulk I could use? Any other ideas on how to keep it stable?

- I'm guessing that you haven't installed it yet? When you attach it firmly to both the floor and ceiling, it should become very stable. I don't think that you'll have to add any structure. (Unless she has a really big cat...)

- Q:Wood board and PVC board with what glue combination

- Universal glue full coating, thin coating, pressure paste. Or glass paste point paste.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Modern And Minimalism PVC Ceiling Designs For Bedroom

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords