Printed PVC Foam Board/PVC Foam/PVC Roof Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

PVC Foam Sheet, a kind of high-tech product, is produced by special machinery and technology processing. The main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as glossy or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

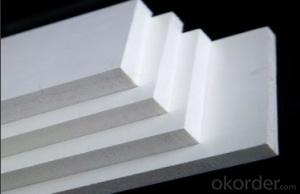

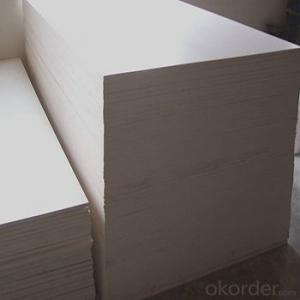

3.Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm,as your request.

Thickness:1-33mm,

Density:0.35-0.9

4. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

5.Easily to put protective film on one or two sides

6.Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

5.Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4. Sanitarywares, kitchen cabinet, washroom cabinet.

5.Advertisment

6.Contruction

6.FAQ

1. If the products have some quality problem ,how will you deal with it?

Answer : If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

2. Could you provide samples?

Answer : Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

7.Pictures of Products and Factory

- Q: F grade sheet and EO-class plate, what is the difference between these two, Guiqiu master answer, buy a furniture to the market a question, really a headache? Which is good?

- In general, if you export to Japan, you must provide F4 star certification. And E0 is our national standard (methanol content ≤ 5mg / 100g). F4 star standard is much higher than the E0 standard.

- Q: Do you know the top of the wardrobe?

- The top solid wardrobe is made of high quality plate, special process, moisture resistance, formaldehyde emission meet the E1, E0 environmental standards, with anti-deformation, anti-mildew pest control, anti-acid, anti-scratch, recyclable The use of double-track single pull pulley, the last round of the United States DuPont pu materials, the next round of modified pps material, with wear-resistant, muffler, bearing the strong and so on. With the top of a special top and bottom seal, completely put an end to dust. The top of the wardrobe pulley is the international top of the sliding system, tight seal.

- Q: I went to the optical shop to see the frame, the shopkeeper asked me to be good or the general, I said a little better when he took me a pure titanium, and asked the price surprised. I find a pick when he said, he said that the plate, the price is more than 100 I now use the plastic, the frame to buy when only 20 yuan. In the end what kind of frame should be good for it? I hope the price will not exceed 150 yuan

- Frames should be based on the face of the selection; face thin with a thin point of the frame is better. But also with the length of time wearing glasses also have to contact every day wearing a long time to choose a light point of the glasses, to avoid the nose pressure change type. In fact, the most important thing is the lens, the quality of things now vary widely, you have to choose a high light, wearable, safe, and their favorite. Also, male and female wear frames are not the same. Pure titanium, high-grade some corrosion-resistant, but also anti-magnetic. Large face of the plate do not use, round face is not appropriate. It is best to wear to see.

- Q: TR-90 cp pc plastic glasses frame difference, as well as what is the material sheet! Physical properties how?

- TR90 spectacle frame surface lubrication, the density of 1.14-1.15, on the saline will float, than other plastic glasses frame light, about half of the weight of the plate material, nylon material is 85%, can reduce the bridge of the nose, the burden of the ear, suitable for young people . It is very resistant to wear, good chemical resistance, solvent resistance, weather resistance is good, not easy to burn, high temperature. And it is memory of the polymer material, anti-deformation index 620kg / cm2, not easy to change because TR90 material Eyeglass frame elasticity, toughness, easy to break, strength, no rupture, so it has sports safety. And it is very resistant to impact: more than 2 times the nylon material, ISO180 / IC:> 125kg / m2 elasticity to effectively prevent In the movement due to impact on the eye damage. No chemical residue release, in line with European food-grade materials requirements. TR90 material than other pc, cp and other frames material is much more expensive, and the production process is also more stringent, so TR90 glasses frame price than the other to be several times more expensive. CP: refers to propionic acid frames PC: refers to the plastic frames, made of polycarbonate Material: The material is made of high-tech plastic memory plate. Ingredients: Most of the current sheet metal components are acetate fiber, there are a few high-grade frame is propionic acid fiber, while the acetate fiber sheet is divided into injection molding and pressing Type, injection molding is the name of the mold is made of water, but most of the current is to suppress the processing of sheet metal glasses in terms of the origin of the plate in France and Italy, the plate is better, Japan is also quite good, many high-end sheet glasses Based on these high-quality sheet, and therefore more reliable quality.

- Q: How to change the cabinet board is not Jilin forest workers dew river plate

- Plate above the logo, but even if the e1-level moisture-proof board also used a few years Kazakhstan

- Q: Bathroom and kitchen ceiling selection of what kind of plate is better?

- Proposed toilet with a closed aluminum plate hanging ceiling, moisture effect is very good. The kitchen can choose the color with aluminum slab plate, easy to disassemble, at any time to remove the wipe, it is recommended to avoid wither with strong acid and alkali.

- Q: Which master please teach about aluminum alloy doors and windows under the material calculation method? Flattened; push-pull can be the best example. Thank you!

- Aluminum alloy cutting can be used plasma cutting machine, high pressure water jet cutting machine and laser cutting machine and other cutting equipment. These three different cutting methods have their own advantages and disadvantages, according to the needs of the product, the use of different equipment to process aluminum alloy raw materials. 1. Plasma cutting Plasma cutting is a high-temperature plasma arc as a heat source, the local melting of the cutting metal, while the use of high-speed air flow will melt the metal blown to form a narrow incision of a process. Hydrogen as a cutting gas, argon as arc gas, nitrogen is vortex gas, cooling the torque of the various components and blown away the molten metal. The advantages of plasma cutting are: processing speed, the plate and large sheet metal processing capacity. But the plasma cutting products need to secondary processing, cutting the arc produced by large, gas smoke toxic, greater environmental pollution.

- Q: Decoration need to buy snow Ling plate, the plate how?

- Snow surface plate product shape flat, thick and large ratio, the unit volume of the surface area is also great, this shape features to bring its use on the characteristics: (1) surface area, so inclusive capacity, in the chemical, container, construction (2) can be arbitrarily tailored, bending, stamping, welding, made of various components of the product, the use of flexible and convenient, in the automotive, aviation, shipbuilding and tractor manufacturing and other sectors occupy a very large number of metal products, metal products, metal structure, Important position; (3) can be bent, welded into various types of complex sections of steel, steel, large I-beam, channel and other structural parts, it is called "universal steel."

- Q: What are the types of decorative plates?

- Decorative sheet types are blockboard, plywood, decorative panels, MDF, Glulam, Particleboard, Fireboard, Gypsum board, PVC sheet, Aluminum plate, Aluminum plate, 3D board. Xiaobian today to simply introduce you to Glulam and PVC sheet two common life of the plate. Decorative materials are divided into two parts: part of the outdoor materials, part of the indoor materials. Indoor materials and then divided into stone, sheet, sheet, profile, wire five types. Decorative sheet is the general term for all plates, mainly: blockboard, plywood, decorative panels, MDF, Glulam, Particleboard, Fireboard, Gypsum board, PVC board, Aluminum gusset plate, Aluminum plate,

- Q: Comparison of fire and water of the plate

- Solid wood is the best, the most upscale

Send your message to us

Printed PVC Foam Board/PVC Foam/PVC Roof Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords