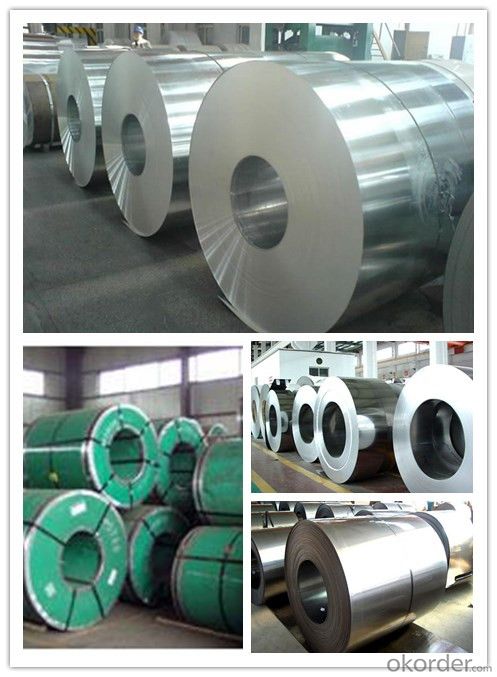

Prime Cold Rolled Carbon Steel Coils with SPCC-SD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description .

Model NO.:SPCC SPCD SPCE ST12-15 DC01-06

Surface Treatment:Coated

Certification:ISO

Technique:Cold Rolled

Standard:ASTM, JIS, GB, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:SPCC SPHC

Certificate:ISO 9001-2008, SGS, CE, BV

Width:600-2000mm

Thickness:0.11-3.0mm

Inside Diamete:508mm or 610mm

Delivery Time:10-15days After Receipting The Advance Payment

Export Markets:South America, Eastern Europe, Southeast Asia, Oceania, Mid East, Eastern Asia, Western Europe

Additional Info.

Trademark:Sino Steel-Cold Rolled Carbon Steel Coil

Packing:Standard Export Package

Standard:SGS, CIQ, BV, ISO, CE

Origin:China

HS Code:72091790

Production Capacity:10000tons/Month

Product Description

Cold Rolled Carbon Steel Coil:

Products Detail:

Thickness:0.11-3mm

Width:600-2000mm

Length:as your need

Standard:AISI, ASTM, BS, DIN, GB, JIS

Grade;SPCC/SPCD/SPCE/ST12-15/DC01-06.

Delivery time:15-20days after receipting the advance payment.

Package: Standard export packing or as your requested.

Technique:

Surface Treatmentunoil,dry,chromate passivated, non-chromate passivated

Application:Widely used in ships, automobiles, bridges, buildings, machinery, etc

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

>

- Q: What is the process of slitting steel coils into narrower strips?

- The process of slitting steel coils into narrower strips involves unwinding the steel coil and passing it through a set of rotating circular blades. These blades cut the coil into narrower strips of the desired width. The strips are then rewound onto separate coils or packaged for further processing. This slitting process allows for the production of multiple narrower strips from a single large coil, making it more versatile and efficient for various applications.

- Q: looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who answer. i'm leaning towards white-2 steel for my first sashimi knife, started training on the sushi bar and need a new tool!

- Steel Sushi

- Q: what are the properties that can strengthen the steel to withstand earhquake?

- Well, its not necessary how strong steel is but how buildings are designed that withstands earthquakes. Steel as a property has to elastic qualities and when earthquakes are initiated but moving of the plates, the building has to absorbed the effects of the earth movements while remain standing. This does not necessary mean that the building will be usable afterward but it has to remain standing. Now, how does a building remain standing? All building have within its design a VLLRS (vertical lateral load resisting system). This system is basically designed to resist earthquake loads as well as wind loads. In steel buildings, this system is usual made of OMF (Ordinary moment frames) or braced frames. These frames act to absorb the lateral loads and transmit them into the foundation below. If the structure was concrete, there would still be moment frames made of concrete and steel but you know that concrete has a elasticity that is less than steel. ALthough there elasticity is less, they are stiffer and concrete structure tend to resist more lateral load because of it. In concrete, we can create shear walls which are basically walls that are thick and wide to resist lateral load from earthquake and wind. Masonry has even a lesser strength than steel or concrete and wood even less than above. What makes them usful is how they are used to resist earthquake loads or lateral loads from earthquake and wind. So, to answer your question, its not nessary how strong the steel is but how the material is used to resist earthquake is what is important.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- There is going to be too much stress at that mounting point for jb to work for long, unless you plan on never leaning more than 5 degrees from prostrate. Buy a new or used one. They are cheap if your not too picky. If you do plan on using jb, i highly recommend drilling multiple 1/8 or so holes on both sides of the crack, and smash some jb into those holes as you patch it. That will allow the jb to hold on much better.

- Q: How are steel coils used in the manufacturing of medical equipment?

- Steel coils are commonly used in the manufacturing of medical equipment as they serve as a crucial component in various applications. These coils are often employed in the construction of medical devices such as surgical instruments, orthopedic implants, and diagnostic equipment. The high strength and durability of steel make it ideal for these purposes, ensuring the longevity and reliability of the medical equipment. Additionally, steel coils are used in the production of medical furniture, such as hospital beds and examination tables, providing stability and support. Overall, steel coils play an essential role in the manufacturing of medical equipment, contributing to the quality and functionality of these devices.

- Q: Can steel coils be coated with phosphorescent materials?

- Yes, steel coils can be coated with phosphorescent materials. Phosphorescent coatings can be applied to steel coils to create a glowing effect in low-light conditions.

- Q: How are steel coils used in the manufacturing of springs?

- Steel coils are used in the manufacturing of springs by being formed into a helical shape, allowing them to store and release energy when subjected to force or pressure.

- Q: tinplate,hot rolled coil,hot rolled sheet,cold rolled coil,cold rolled sheet,d bar,wire rod,triangle,structural steel,steel pipe,steel tube,carbon steel pipe

- Here are the top 30 steel producing companies in the world, listed by the megaton output: 1. 63.0 Mton Mittal Steel Company NV (Global) [2] 2. 46.7 Mton Arcelor (Europe) [3] 3. 32.0 Mton Nippon Steel (Japan) [4] 4. 30.5 Mton POSCO (South Korea) [5] 5. 29.9 Mton JFE (Japan) [6] 6. 23.8 Mton Shanghai Baosteel Group Corporation (China) 7. 19.3 Mton United States Steel Corporation (United States) 8. 18.4 Mton Nucor Corporation (United States) 9. 18.2 Mton Corus Group (Europe) [7] 10. 17.5 Mton Riva Group (Europe) [8] 11. 16.5 Mton ThyssenKrupp (Europe) [9] 12. 16.1 Mton Tangshan (China) 13. 13.9 Mton EvrazHolding (Russia) 14. 13.7 Mton Gerdau (Brazil) 15. 13.6 Mton Severstal (Russia) 16. 13.5 Mton Sumitomo Metal Industries (Japan) 17. 13.4 Mton SAIL (India) 18. 12.0 Mton Wuhan Iron and Steel (China) 19. 11.9 Mton Anshan (China) 20. 11.4 Mton Magnitogorsk (Russia) 21. 10.5 Mton Jiangsu Shagang (China) 22. 10.5 Mton Shougang (China) 23. 10.4 Mton Jinan (China) 24. 10.3 Mton Laiwu (China) 25. 10.3 Mton China Steel (Taiwan) [10] 26. 9.6 Mton Maanshan 27. 9.4 Mton Imidro 28. 8.7 Mton Techint 29. 8.7 Mton Usiminas (Brazil) 30. 8.5 Mton Novolipetsk (Russia)

- Q: How are steel coils used in the production of metal bridges?

- Steel coils are an essential component in the production of metal bridges due to their versatility, strength, and durability. These coils are typically made from high-quality steel alloys, which provide the necessary structural integrity required for constructing bridges. The first step in using steel coils for bridge production is processing them through a series of manufacturing techniques. The coils are uncoiled and straightened to remove any distortions or bends. Then, they are cut into precise lengths according to the bridge's design specifications. Once the steel coils have been processed, they are transformed into various structural components used in bridge construction. These components include beams, girders, trusses, and plates. Beams and girders are typically used for the main support structure of the bridge, while trusses provide additional support and stability. Plates are used for the bridge deck, providing the surface on which vehicles and pedestrians travel. Steel coils also play a crucial role in the fabrication of bridge connections and joints. These connections are essential for transmitting loads and forces throughout the bridge structure, ensuring its stability and safety. Steel coils are used to create various connection elements such as bolts, nuts, washers, and welded sections. Furthermore, steel coils are commonly employed in the production of bridge reinforcements. Reinforcing steel bars, also known as rebars, are manufactured from steel coils. These rebars are used to strengthen concrete elements within the bridge, such as columns, piers, and abutments, enhancing their load-bearing capacity and resistance to bending and tension. In addition to their structural applications, steel coils are also used for protective coatings on metal bridges. Coils can be coated with specialized materials such as zinc, epoxy, or paint to prevent corrosion and increase the lifespan of the bridge. These coatings help to maintain the structural integrity of the bridge, especially in harsh environments where exposure to moisture, chemicals, and weathering factors is high. Overall, steel coils serve as the backbone of metal bridge production. They are transformed into various structural components, connections, reinforcements, and protective coatings that ensure the strength, durability, and longevity of the bridge.

- Q: What are the common uses of galvanized steel coils?

- Galvanized steel coils are commonly used in various industries such as construction, automotive, and manufacturing. They are primarily used for making metal roofs, walls, and fences due to their corrosion-resistant properties. Additionally, galvanized steel coils are utilized in the production of air conditioning ducts, electrical appliances, and agricultural equipment.

Send your message to us

Prime Cold Rolled Carbon Steel Coils with SPCC-SD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords