PREPAINTED STEEL COIL JIS G 3312 CGCC WITH HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25.00 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

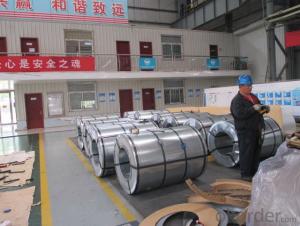

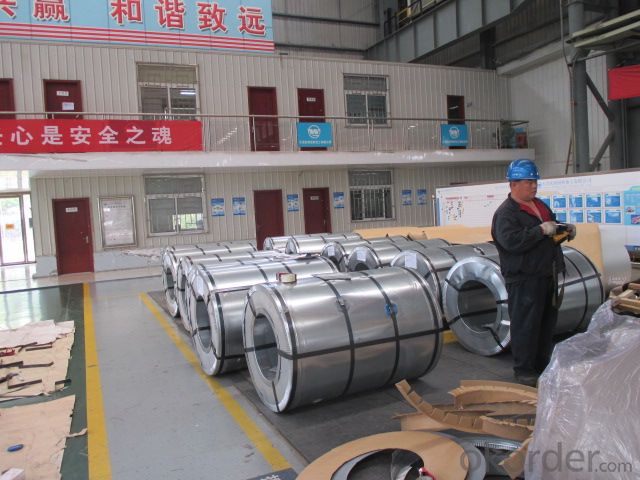

PREPAINTED STEEL COIL

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

PREPAINTED STEEL COIL

Technical Standard: JIS 3312

Grade:CGCC

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package: Properly packed for ocean freight exportation in 20''container

Application:: home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: I'm a big fan of stainless steel and sterling silver, but not of the humidity of the country I'm in. Therefore I sweat more. Gross, I know. I'm buying a necklace chain for my ring.So does sweat contribute to tarnishing of silver and steel? The real kind?

- steel shouldn't really tarnish, it rusts and moisture increases that. Silver tarnishes when exposed to air and sulfur. Moisture increases the process a bit, but it happens anyway. Sweat is not gross, it's a necessary function of your body, otherwise you would die. A lot of sports people wear jewelry and they sweat a lot. If you wear the jewelry all the time, that will prevent the tarnish a bit. If you take it off, clean it (water and dish washing liquid), dry it and put it in a zip lock back to keep it away from air and moisture. In the end, cleaning the jewelry is quick and easy so don't worry about it.

- Q: What are the common coil loading and unloading procedures?

- The common coil loading and unloading procedures typically involve the use of specialized equipment such as cranes or forklifts to safely lift and transport the coils. The procedure may vary depending on factors such as the size and weight of the coils, as well as the specific requirements of the industry. Generally, the coils are loaded or unloaded by carefully positioning them onto or off of a designated storage area or transportation vehicle. The process often includes securing the coils with straps or clamps to prevent any movement or damage during transportation. Proper handling and adherence to safety protocols are crucial to ensure the successful loading and unloading of coils.

- Q: i'm looking into buying a stainless steel ring for somebody as a gift.i'm on a budget (heh) and the ring is about $50.will it rust or tarnish? it'd be embarrassing if i gave it to someone, and it begins rusting :Pthanks

- Stainless Steel does not rust...that is why it is used in our kitchens and the top kitchens of the world...!! sorry...Stainless Steel does not Tarnish either!

- Q: What is the role of steel coils in the manufacturing of agricultural machinery?

- Steel coils play a crucial role in the manufacturing of agricultural machinery as they are used to fabricate various components and parts such as frames, chassis, blades, and implements. The high strength and durability of steel make it an ideal material for withstanding the harsh conditions and heavy-duty applications that agricultural machinery often faces. Additionally, the versatility of steel coils allows manufacturers to customize and shape them into different forms and sizes, ensuring the production of reliable and efficient agricultural machinery.

- Q: How are steel coils used in the production of marine vessels?

- Steel coils are used in the production of marine vessels primarily for their strength, durability, and corrosion resistance. These coils are shaped and formed into various components such as hulls, decks, and bulkheads, providing a sturdy framework for the entire vessel. By utilizing steel coils, marine vessels gain the necessary structural integrity to withstand harsh marine environments and ensure the safety and reliability of the vessels.

- Q: What are the factors to consider when selecting steel coils for a specific application?

- When selecting steel coils for a specific application, there are several factors that need to be considered. These factors include the type of application, the required strength and durability, the desired aesthetic appearance, the budget, and any specific industry standards or regulations that need to be met. Firstly, it is important to determine the type of application for which the steel coils will be used. Different applications may require different types of steel with varying properties. For example, if the coils will be used in structural construction, high-strength steel with excellent structural integrity may be required. On the other hand, if the coils will be used in automotive manufacturing, steel with good formability and weldability may be more suitable. The required strength and durability is another crucial factor to consider. This includes factors such as the load-bearing capacity, resistance to corrosion, and ability to withstand extreme temperatures or environmental conditions. The steel coils must be able to withstand the specific stresses and strains that will be placed upon them in the intended application. The desired aesthetic appearance is also important, especially in applications where the steel coils will be visible. Factors such as the surface finish, color, and texture of the steel coils may need to be considered. This is particularly relevant in industries such as architecture or interior design, where the visual appeal of the steel is a key consideration. Budgetary constraints should also be taken into account when selecting steel coils. Different grades and types of steel can vary significantly in price. It is important to find a balance between the desired properties and the available budget. Sometimes, it may be necessary to compromise on certain factors in order to meet budgetary constraints. Lastly, any specific industry standards or regulations should be considered when selecting steel coils. Certain industries, such as aerospace or automotive, may have strict requirements for the materials used in their products. In such cases, it is crucial to ensure that the selected steel coils meet all necessary standards and regulations. In conclusion, when selecting steel coils for a specific application, factors such as the type of application, required strength and durability, desired aesthetic appearance, budget, and industry standards or regulations should all be carefully considered. By taking these factors into account, one can make an informed decision and choose the most suitable steel coils for their specific application.

- Q: How are steel coils used in the manufacturing of conveyor belts?

- Steel coils are used in the manufacturing of conveyor belts as they provide strength, durability, and flexibility to withstand the heavy loads and continuous movement experienced in conveyor systems. The coils are shaped into a continuous loop, forming the core structure of the belt, which is then covered with various materials to enhance grip, prevent slipping, and improve overall performance.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials by being unwound and flattened to create the wire used for fencing. The steel wire is then further processed and shaped into different forms, such as chain link or barbed wire, to meet specific fencing needs.

- Q: How are steel coils used in the manufacturing of tools?

- Steel coils are used in the manufacturing of tools as they provide a strong and durable material for the construction of various tool components. The coils are processed and shaped into specific forms, such as blades or handles, through cutting, shaping, and heat treatment processes. The resulting steel tool parts exhibit excellent strength, toughness, and resistance, making them suitable for a wide range of applications in industries like construction, automotive, and manufacturing.

- Q: What are the common coil handling challenges?

- Some common coil handling challenges include the difficulty in safely lifting and moving heavy coils, ensuring proper alignment and positioning during handling, preventing damage to the coils or surrounding equipment, and efficiently managing coil storage and retrieval.

Send your message to us

PREPAINTED STEEL COIL JIS G 3312 CGCC WITH HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25.00 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords