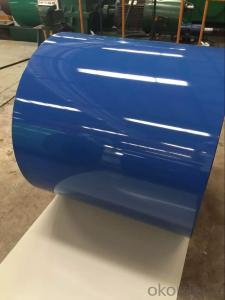

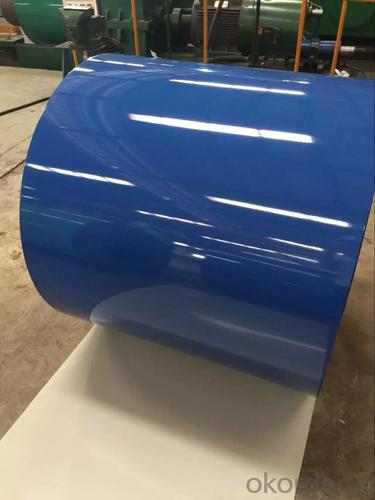

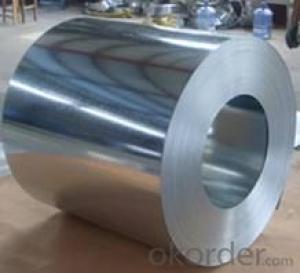

prepainted hot dipped galvanized steel coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

we have devoted to manufacture steel coils for 13 years. As the biggest manufacture in Hebei China, we have two large factory and 8 production lines, sincerely welcome to your visit if possible.

1, Production Introduction: PPGI are prepainted galvanized steel coils, used for making roof, advantage is can be used at least 10 years.

2, Product feature:

① We're factory, products has the best price for you.

② We have 8 production lines, have the fastest delivery time for order

③ All colors can be produced by our factory.

④ Product can accept any test before shipment.

3,Parameter list:

① Product Name:PPGL

②Thickness:0.2-1.0MM

③ Width:914-1250MM

④ Az Coating:30-275 G/M2

⑤Coil Weight:3-5MT

⑥Coil ID:508MM

⑦Packing :Standard Export Seaworthy Shipping Packaging

⑧Payment Terms:30% T/T in advance, 70% balance within 3 working days against the copy of B/L Or irrevocable LC at sight

⑨Delivery Time:

10 days after advance is confirmed if order≤100MT

15 days after advance is confirmed if 100MT≤order≤200MT

20 days after advance is confirmed if 200MT≤order

4,

- Q: what happened to all the steel beams from the WTC buildings? did anyone do any forensic analysisof any of the steel?

- some of the steel was recycled into a warship. I am not sure at what you are trying to get at with the forensic analysis of the steel. There is no conspiracy involving the towers outside of planes crashing into them despite what a lunatic fringe want you to think.

- Q: Is steel harder than iron or is iron harder than steel?Please explain... and help!Thanks

- steel is harder than iron Iron is a chemical element. It is a strong, hard, heavy gray metal. It is found in meteorites. Iron is also found combined in many mineral compounds in the earth's crust. Iron rusts easily and can be magnetized and is strongly attracted to magnets. It is used to make many things such as gates and railings. Iron is also used to make steel, an even harder and tougher metal compound. Steel is formed by treating molten (melted) iron with intense heat and mixing it (alloying) with carbon. Steel is used to make machines, cars, tools, knives, and many other things.

- Q: - I'm considering doing my physics coursework on the uses of Mild Steel in skyscrapers and construction, would this be right? Some sources tell me mild steel is too weak, others say it is fine

- Mild steel doesn't really mean anything, technically. In today's world all steel is mild steel unless it's high carbon or alloy, which are mostly tool steels. You'll need to study steel much deeper than that to accomplish any real physics work relating to steel.

- Q: I looking at replacing a few of the panels on my car with either Carbon Fiber or High Tensile Steel to shave off some weight and increase mpg and take some time off my quarter mile. Which is better: Carbon Fiber or High Tensile Steel?

- Because no matter how hard the helmet is it can not prevent brain damage from your brain slapping the inside of your skull. If the helmet was able to absorb the energy from an impact and prevent you brain from moving inside your skull it would have to be huge and everyone would look like bubble heads riding on bikes. The sides would have to be around 12 inches thick on each side and top to provide that much protection and would probably break your neck if you were in a wreck. Hope I have been helpful.

- Q: What is the maximum load capacity for steel coil storage racks?

- The maximum load capacity for steel coil storage racks can vary depending on various factors such as the design, dimensions, and specifications of the rack. It is recommended to consult the manufacturer or supplier for the specific load capacity of the steel coil storage rack you are using.

- Q: Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- If it is calculated in accordance with the board, then his sales price should be 1*1*2*7.93*10=158.6 yuan / ZhangIf it is calculated according to the volume (assuming that the sales price is consistent), 0.9*1*2*7.93*10=142.7 yuan / ZhangSimilarly, a piece of stainless steel, if sold at the same price, leads to different prices. So in order to let both plate or rolling up to the same price, the price will be lower than the plate volume price, so the same with the price of the goods..The specific proportion of their conversion, can calculate the price of the goods in accordance with the principle of.

- Q: How are steel coils inspected for quality assurance?

- Steel coils are inspected for quality assurance through a rigorous process that involves various tests and checks. Firstly, visual inspection is conducted to look for any surface defects such as scratches, dents, or rust. This ensures that the coils are in good condition and free from any obvious flaws. Next, dimensional inspection is performed to verify the dimensions and tolerances of the coils. This involves measuring the width, thickness, and length of the coils to ensure they meet the specified requirements. Any deviations from the standard dimensions are noted and addressed. Additionally, mechanical testing is carried out to assess the strength and durability of the steel coils. This includes conducting tensile tests to measure the strength and elasticity of the steel, as well as impact tests to evaluate its ability to withstand sudden loads or shocks. Furthermore, chemical analysis is conducted to determine the composition and purity of the steel. This involves taking samples from the coils and analyzing them in a laboratory to check for the presence of any impurities or elements that may affect the quality of the steel. To ensure the coils meet specific industry standards, non-destructive testing methods such as ultrasonic testing or magnetic particle inspection may be employed. These techniques allow for the detection of internal defects or irregularities that may not be visible to the naked eye. In addition to these tests, the coils may undergo surface treatment inspections, such as galvanization or coating checks, to ensure the protective layers are applied correctly and meet the required specifications. Overall, steel coil inspection for quality assurance involves a combination of visual, dimensional, mechanical, chemical, and non-destructive testing methods. These comprehensive inspections help to ensure that the steel coils meet the necessary quality standards and are suitable for their intended applications.

- Q: What are the different types of steel coil packaging systems?

- There are several different types of steel coil packaging systems, including stretch wrapping machines, coil wrapping machines, steel coil strapping machines, and steel coil wrapping and strapping machines. These systems are designed to securely package steel coils for storage and transportation, providing protection against damage and ensuring safe handling.

- Q: What is the process of recycling steel coils?

- The process of recycling steel coils involves several steps to ensure the maximum utilization of the material and to minimize waste. Firstly, steel coils are collected from various sources, including industrial manufacturing facilities, construction sites, and scrap yards. These coils are then transported to a recycling facility where they undergo a thorough inspection to assess their quality and determine the appropriate recycling method. Next, the steel coils are cleaned to remove any contaminants such as dirt, oil, or paint. This is typically done using chemical agents or mechanical processes, depending on the level of contamination. Cleaning the coils is crucial as it ensures the quality of the recycled steel. After cleaning, the coils are shredded or sheared into smaller pieces to facilitate further processing. This step helps to increase the surface area, making it easier to separate the steel from other materials that might be present in the coils. Once the coils are broken down into smaller pieces, they go through a process known as magnetic separation. This involves passing the steel pieces through a magnetic separator that uses powerful magnets to attract and separate the ferrous steel from non-ferrous materials like aluminum or plastic. This separation is essential as it ensures the purity of the recycled steel. The separated steel pieces are then melted in a furnace at extremely high temperatures. This melting process not only removes any remaining impurities but also allows the steel to be molded into various shapes and forms, depending on the intended application. After melting, the molten steel is poured into molds or cast into ingots to solidify. These ingots can be further processed and transformed into new steel products or used as raw material in various industries. Throughout the recycling process, the steel coils are subjected to quality control measures to ensure that the resulting recycled steel meets the required specifications and standards. This includes conducting chemical analyses and mechanical tests to verify the strength, composition, and overall quality of the recycled steel. In conclusion, the process of recycling steel coils involves collecting, cleaning, shredding, separating, melting, and molding the steel to produce new products or raw material. This process not only helps to conserve valuable resources but also reduces the environmental impact associated with traditional steel production.

- Q: How are steel tape measures installed?

- Today, I met similar situations at work! Accidentally pull the head, and then automatically can not go back, after opening, winding, after installation, can not automatically withdraw! After a long time, we suddenly noticed that we neglected a small place!

Send your message to us

prepainted hot dipped galvanized steel coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords