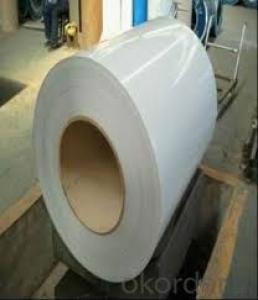

Prepainted Galvanized Steel in coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Prepainted Galvanized Steel

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: HBSTEEL

Specifications OfPrepainted Galvanized Steel

Thickness 0.20-1.2mm (BMT) Width 600-1250mm |

Zinc Coating 100-275g/m2 |

Color According to RAL color fan or as per request |

Internal Diameter 508mm or 610mm |

Coil Weight 3-6MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Applications OfPrepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

- Q: What are the typical tolerances for steel coils?

- The typical tolerances for steel coils depend on various factors such as the specific grade of steel, the manufacturing process, and the intended application. However, some common tolerances for steel coils include thickness tolerances of +/- 0.005 to 0.010 inches, width tolerances of +/- 0.020 to 0.050 inches, and length tolerances of +/- 0.125 to 0.250 inches. These tolerances ensure that the steel coils meet the required specifications and can be used efficiently in different industries such as automotive, construction, and manufacturing.

- Q: i'm looking into buying a stainless steel ring for somebody as a gift.i'm on a budget (heh) and the ring is about $50.will it rust or tarnish? it'd be embarrassing if i gave it to someone, and it begins rusting :Pthanks

- Stainless Steel does not rust...that is why it is used in our kitchens and the top kitchens of the world...!! sorry...Stainless Steel does not Tarnish either!

- Q: PLEASE PLEASE PLEASE!!!!!!!! HELP MEEEEEEEE!!!!!!! I need to know how can i prevent steel from rusting when it is exposed to water or salt water or vinegar. PLEASE TELL ME A LOT OF WAYS THAT I COULD PREVENT IT!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- cathodic protection

- Q: What are the quality control measures for steel coil production?

- Quality control measures for steel coil production are essential to ensure that the final product meets the required standards and specifications. Here are some key quality control measures commonly employed in the steel coil production process: 1. Raw Material Inspection: Before production starts, the raw materials such as steel billets are thoroughly inspected for their chemical composition, mechanical properties, and surface defects. This ensures that only high-quality materials are used in the production process. 2. Process Control: Throughout the production process, various process control measures are implemented to monitor and control critical parameters. These may include temperature control, rolling speed, tension control, and lubrication. Regular checks and adjustments are made to ensure that these parameters are within the specified tolerances. 3. Dimensional and Surface Inspection: Steel coils undergo rigorous dimensional and surface inspections to ensure that they meet the required thickness, width, and length specifications. Surface defects such as scratches, pits, or dents are also carefully examined and minimized to meet quality standards. 4. Mechanical Testing: Mechanical properties such as tensile strength, yield strength, elongation, and hardness are tested on a regular basis. These tests are crucial to ensure that the steel coils possess the desired strength and performance characteristics. 5. Visual Inspection: Visual inspection is an important quality control measure to identify any visible defects or irregularities in the steel coils. Trained inspectors check for issues like cracks, corrosion, or uneven surfaces, and take necessary actions to rectify or reject the faulty coils. 6. Non-Destructive Testing: Non-destructive testing methods like ultrasonic testing, magnetic particle testing, or eddy current testing are often employed to detect internal defects such as voids, inclusions, or discontinuities that may impact the quality of the steel coils. 7. Documentation and Traceability: Proper documentation and traceability of all quality control measures are maintained throughout the production process. This includes recording test results, inspection reports, and other relevant data to ensure transparency and accountability. 8. Continuous Improvement: Quality control measures in steel coil production are not static but subject to continuous improvement. Regular audits, feedback from customers, and analysis of process data are used to identify areas for improvement and implement corrective actions to enhance product quality. By implementing these quality control measures, steel coil manufacturers can ensure that the final product meets the required specifications, performs reliably, and achieves customer satisfaction.

- Q: an 18k steel and gold, screw style bracelet how much would it be worth?

- Steel does not come in an 18k version and is worth only about $1.50/pound. 18k gold (.750 or 75% pure) is currently worth about $40.20/gram, based on the spot price of gold of $1,667/ounce at this moment.

- Q: I know that steel is generally iron with carbon and probably some other things in it, but I'm doing a research paper on architecture in Tokyo, and touching on the Tokyo Tower.The Tokyo work is larger than the Eiffel Tower by 12 meters, but lighter by 3000 tons. The only reason I can find for the difference in weight is that the Tokyo Tower is made of steel and the Eiffel Tower in made of iron, and since the Tokyo Tower is modeled after the Eiffel, there's really not a substantial difference in the amount of metal used....

- Steel Lighter

- Q: I have my grandpa's navy knife from ww2, a mk2 combat knife i think, and i was wondering what type of steel it is made of. I'm guessing it's a high carbon steel, i'd just like to know exactly what grade.

- I would get a 1095, serrated edge, tanto style, with either a good quality rubberized or bone handle.

- Q: What are common uses for steel coils?

- Steel coils are commonly used in various industries such as automotive, construction, and manufacturing for applications like sheet metal fabrication, structural components, pipes, and electrical appliances.

- Q: I was wondering what kind of company casts and sells steel without acting as a contractor as well. They only sell steel no install it

- If you are talking about raw steel materials and products I believe you are talking about a steel processor and warehouse company or a steel distributor. There are many different points along the steel manufacturing process that you could buy steel products. It would depend on various factors. Depending the amount, type, grade, gauge, properties, origin and a host of other elements you could purchase the steel in billet, plate, diamond plate, rolled sheet (cold or hot), coil, beam, stamped, pickled, scrapped, etc. You get the idea. Now I don't know where you are in the world, but you can go to one of the two sites below, which I have used for product sourcing and research before. The last one is a major manufacturer that I have actually been to. I hope this helps.

- Q: How are steel coils used in the manufacturing of heat shields?

- Steel coils are used in the manufacturing of heat shields as they provide a durable and heat-resistant material to create the shield. The coils are typically cut and shaped into the desired form, allowing for precise customization and efficient production. The steel's high melting point and strength make it ideal for shielding against intense heat, ensuring the protection of surrounding components or structures.

Send your message to us

Prepainted Galvanized Steel in coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords