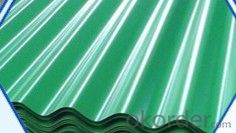

PREPAINTED CORRUGATED STEEL SHEET WITH BRIGHT

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PPGI/GI Corrugated Steel Sheet/Metal Roofing

specifications

thickness:0.15-0.6mm

width:600-1250mm

zinc coating:60-180g/m^2

certificates:

ISO 9001:2008 QS-9000

Entity factory

2. Galvanization or hot dip

3. (0.12-1.5)*1250mm or under

4.SGCC/JIS/G3302/DX51D

5.A competitive pricePPGI /COLOR STEEL/ CGCC

PPGI /CCLI /CGLCC /PREPAINTED STEEL COIL/SHEET

COLOR: RAL STANDARD

CGCC DX51D DX52D Q235/Q195L

application:

commercial use, structural use, household appliance, light industry, constructure

wear resistant steel, high-strength steel plate

| product | corrugated metal roofing sheets |

| Brand | CNBM |

| supply ability | 250,000 tons per year |

| base material | galvanized steel sheet |

| thickness | 0.15-0.6mm |

| width | 600-1250mm |

| quality | spcc,dx51d,sgcc,sgch |

| zinc-coating | 60-180g/m2 |

| technique | cold rolled-hot dipped galvanizing- corrugated |

| Payment Terms | T/T L/C D/A D/P |

| tolerance | thickness: +/- 0.02mm |

| width: +/-2mm | |

| feature | lowes sheet metal roofing have excellent performance of decoration, corrosion resisitance etc. |

| package | 1. PVC film 2. Anti-water paper. 3. Metal |

- Q: What are the different jointing methods for steel sheets?

- There are several different jointing methods for steel sheets, including welding, riveting, adhesive bonding, and mechanical fastening.

- Q: Can steel sheets withstand extreme temperatures?

- Yes, steel sheets can withstand extreme temperatures. Steel is known for its high melting point, which is around 1370°C (2500°F). This makes it suitable for use in environments with extreme heat, such as furnaces, kilns, and industrial ovens. Additionally, steel has excellent thermal conductivity, allowing it to efficiently transfer heat and resist thermal expansion and contraction. These properties make steel sheets resistant to warping, cracking, and other forms of structural damage that can occur under extreme temperature conditions.

- Q: Can the steel sheets be easily cleaned?

- Yes, steel sheets can be easily cleaned. Steel is known for its durability and ease of maintenance. It can be wiped clean using a damp cloth or sponge with mild soap or detergent. For tougher stains or grime, a non-abrasive cleaner can be used. Additionally, steel sheets are resistant to rust and corrosion, making them suitable for various environments and easy to maintain in the long run.

- Q: How do steel sheets perform in high-humidity environments?

- Due to their inherent properties, steel sheets typically exhibit excellent performance in environments with high humidity. Steel is renowned for its strength, durability, and resistance to corrosion, rendering it a suitable material for enduring conditions characterized by excessive moisture. In certain materials, the presence of high humidity can result in the development of condensation on surfaces, thereby accelerating the corrosion process. However, steel sheets are often endowed with protective layers such as zinc or other corrosion-resistant coatings. These coatings function as a barrier against moisture, effectively preventing the onset of rust. Moreover, steel sheets are frequently subjected to galvanization or treatment with specialized coatings like stainless steel or weathering steel. These measures serve to enhance their resistance to humidity and forestall degradation over time. By providing an additional layer of protection, these coatings ensure that steel sheets retain their structural integrity and continue to perform well even in environments with high humidity. It is worth emphasizing that while steel naturally possesses resistance to moisture, the implementation of proper maintenance and care remains crucial to ensure its long-term performance. Regular inspections, cleaning, and the application of suitable sealants or coatings, if necessary, can further fortify steel sheets against the challenges of high humidity. In conclusion, steel sheets are generally well-suited for high-humidity environments due to their strength, durability, and corrosion resistance. Through the application of appropriate coatings and diligent upkeep, steel sheets can uphold their performance and structural integrity even in conditions characterized by an abundance of moisture.

- Q: How do steel sheets perform in terms of chemical resistance?

- Steel sheets generally have good chemical resistance due to their high corrosion resistance. However, their exact performance can vary depending on the specific type of steel and the chemicals they come into contact with.

- Q: How are steel sheets protected from damage during handling and transportation?

- Steel sheets are protected from damage during handling and transportation through various methods. One commonly used method is the application of a protective coating on the surface of the steel sheets. This coating can be in the form of a special paint or a layer of zinc, known as galvanization. The protective coating acts as a barrier, preventing any moisture or corrosive elements from reaching the steel sheets and causing damage. In addition to the protective coating, steel sheets are often stacked and secured properly to ensure their stability during transportation. They are usually placed on wooden pallets or in specially designed crates to prevent any direct contact with the ground or other surfaces. This helps minimize the risk of scratches, dents, or other physical damage that may occur during handling or transportation. Furthermore, steel sheets are often packaged and wrapped with materials such as plastic or stretch film to provide an extra layer of protection. This packaging helps safeguard the sheets from dust, dirt, and other contaminants that may affect their quality or appearance. Moreover, steel sheets may be equipped with edge protectors made of plastic or cardboard. These edge protectors prevent any impact or compression damage to the edges of the sheets, which are particularly susceptible to deformation. Finally, proper handling and lifting techniques are essential in safeguarding steel sheets during transportation. Employing specialized equipment such as forklifts or cranes with suitable clamps or magnets ensures that the sheets are lifted and moved without causing any bending or warping. Overall, a combination of protective coatings, proper packaging, and careful handling techniques are employed to safeguard steel sheets from damage during handling and transportation, ensuring their quality and integrity upon arrival at their destination.

- Q: Are the steel sheets resistant to impact or bending?

- Yes, steel sheets are generally resistant to both impact and bending due to their high strength and rigidity.

- Q: How do you determine the quality of steel sheets?

- The quality of steel sheets can be determined by evaluating factors such as the grade or type of steel used, its thickness and weight, surface finish, and dimensional accuracy. Additionally, conducting various tests like hardness testing, tensile strength testing, and checking for any defects or impurities can help determine the overall quality and suitability of the steel sheets for a particular application.

- Q: What is the difference between a coated and uncoated stainless steel sheet?

- A coated stainless steel sheet is one that has been treated with a protective layer, such as a polymer or paint, to enhance its resistance to corrosion, scratches, and stains. On the other hand, an uncoated stainless steel sheet does not have any additional protective layer, leaving it more susceptible to these issues.

- Q: How do steel sheets compare to aluminum sheets?

- Steel sheets and aluminum sheets have distinct properties that make them suitable for different applications. Steel sheets are generally stronger and more durable than aluminum sheets, making them ideal for heavy-duty construction, automotive, and industrial applications. On the other hand, aluminum sheets are lighter, have better corrosion resistance, and offer excellent thermal conductivity, making them suitable for aerospace, marine, and electrical applications. Ultimately, the choice between steel and aluminum sheets depends on the specific requirements of the project or application at hand.

Send your message to us

PREPAINTED CORRUGATED STEEL SHEET WITH BRIGHT

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords