Prepainted aluminum zinc rolled Coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

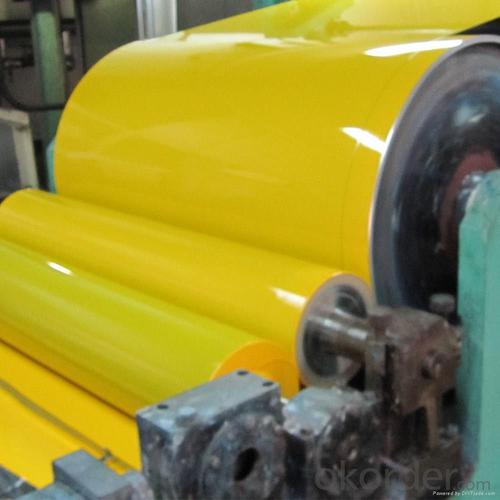

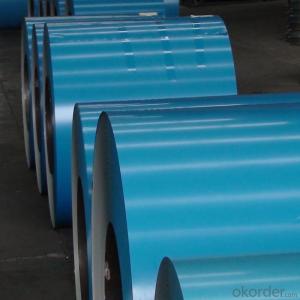

Structure of Aluminum Zinc Rolled Coil

Description of Aluminum Zinc Rolled Coil

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Aluminum Zinc Rolled Coil for Construction Roof

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Aluminum Zinc Rolled Coil for Construction Roof

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Prepainted Aluminum Zinc Rolled Coil for Construction

Product | Hot Dipped Galvanized Steel Coil / Galvalume /Aluzinc Steel coil |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 3-6 tons |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the production of steel rings?

- Steel coils are used in the production of steel rings as the primary raw material. The coils are unrolled and cut into smaller sections, which are then shaped and welded together to form the circular shape of the steel rings.

- Q: Help me compare the speed of sound in air, water, and steel please?Thanks.

- Speed Of Sound In Steel

- Q: Which is more reactive? Zinc or Steel? And why?

- Zinc. Steel is an alloy consisting mostly out of iron, In the reactivity seris, zinc is more reactive than iron. Therefore, zinc is more reactive than steel

- Q: If you were selecting a tool steel for an extreme impact load application, which one would you pick? why?thanks

- It all depends what the application actually is. For hammers I would select a hammer grade B1 steel. For impact loading where an edge is needed I would be going for O1 or similar (oil quenching steels tend to be a little tougher than air hardening). For mining tools a very high manganese steel (Hadfields steel) - this is not a true tool steel. The best place to start is by looking at the ranking of the properties which you want - hardness v toughness v strength - and then use this to put the steels in rank order. Price and availablity then sort the problem out for you (in the real world).

- Q: I am buying a knife for my future husband for his wedding gift and I was wondering what is better carbon steel or stainless steel?

- The better grade of stainless is the top choice, but it can be hard to find, and expensive. - Surgical scalpels are made of it. (Common '420' stainless will not hold an edge as well as high carbon steel.)

- Q: What processes and materials are used in the production of chrome steel

- Go to the process section and find point 6 (explains when alloys are added). Chrome is added at this point, usually in the form of ferrochrome alloy (FeCr). Many kinds of chrome steel also contain nickel. The strengthening effect on steel by forming stable carbide grains at the grain boundaries and the strong increase in corrosion resistance made chromium an important alloying material for steel. The high speed tool steels contain between 3 and 5% chromium.

- Q: Can steel and/or stainless steel turn rusty ?

- from wikipedia: In metallurgy, stainless steel, also known as inox steel or inox from French inoxydable, is defined as a steel alloy with a minimum of 10.5% to 11% chromium content by mass. Stainless steel does not corrode, rust or stain with water as ordinary steel does, but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity, or poor circulation environments. It is also called corrosion-resistant steel or CRES when the alloy type and grade are not detailed, particularly in the aviation industry. There are different grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and resistance to corrosion are required. Stainless steel differs from carbon steel by the amount of chromium present. Unprotected carbon steel rusts readily when exposed to air and moisture. This iron oxide film (the rust) is active and accelerates corrosion by forming more iron oxide, and due to the dissimilar size of the iron and iron oxide molecules (iron oxide is larger) these tend to flake and fall away. Stainless steels contain sufficient chromium to form a passive film of chromium oxide, which prevents further surface corrosion and blocks corrosion from spreading into the metal's internal structure, and due to the similar size of the steel and oxide molecules they bond very strongly and remain attached to the surface.

- Q: What are the different methods of coil end welding for steel coils?

- There are several different methods of coil end welding for steel coils, which include resistance welding, laser welding, and electric arc welding.

- Q: What are the different coil cutting machine options available for steel coils?

- There are several coil cutting machine options available for steel coils, each catering to different requirements and specifications. Some of the common options include: 1. Slitting Machine: This machine is used to slit the large steel coils into narrower strips or slits. It typically consists of a circular blade that moves across the width of the coil, cutting it into the desired widths. Slitting machines can handle a wide range of steel coil thicknesses and are commonly used in industries such as automotive, construction, and manufacturing. 2. Cut-to-Length Machine: This type of machine is used to cut steel coils into specific lengths. It is equipped with a shearing mechanism that cuts the coil based on the programmed length. Cut-to-length machines are particularly useful for applications where precise and consistent lengths are required, such as in the production of steel sheets or plates. 3. Rotary Shear Machine: A rotary shear machine is designed to cut steel coils into smaller pieces or squares. It utilizes a rotating drum with multiple cutting blades that shear the coil in a continuous process. This type of machine is often used in industries that require smaller steel pieces for further processing or assembly. 4. Guillotine Shear Machine: This machine is equipped with a large blade that moves vertically to cut steel coils. It is commonly used in applications where high precision and high-speed cutting are required. Guillotine shear machines can handle thicker steel coils and are often employed in heavy-duty industries such as shipbuilding and metal fabrication. 5. Laser Cutting Machine: Laser cutting machines offer a highly precise and versatile method for cutting steel coils. They use a focused laser beam to melt or vaporize the material, resulting in a clean and accurate cut. Laser cutting machines are suitable for a wide range of steel coil thicknesses and can handle complex shapes and patterns. These are just a few examples of the coil cutting machine options available for steel coils. The choice of machine depends on factors such as coil thickness, desired cutting precision, required output volume, and specific application requirements.

- Q: Can steel coils be used in the production of packaging materials?

- Certainly, packaging materials can indeed utilize steel coils. Frequently, steel coils serve as the primary material in packaging items like metal strapping and steel banding. These coils possess remarkable strength, durability, and exceptional tensile strength, rendering them perfectly suitable for effectively securing and safeguarding diverse products throughout their transportation and storage. Furthermore, steel coils can be effortlessly molded and fashioned into various packaging elements, guaranteeing a dependable and secure packaging solution for an extensive array of industries.

Send your message to us

Prepainted aluminum zinc rolled Coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords