Pre-painted Rolled Steel Coil for Construction Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

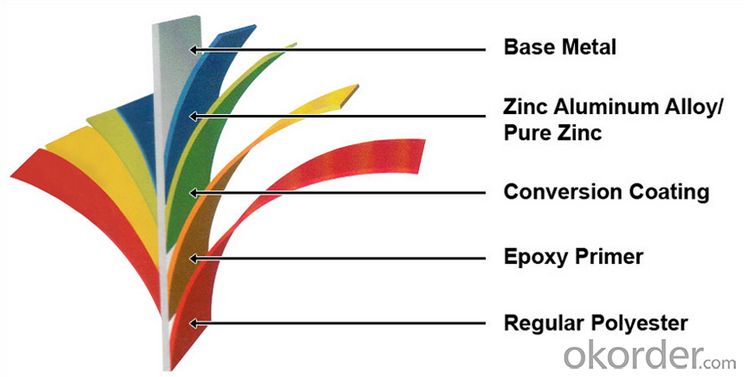

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of coil leveling machines?

- There are three main types of coil leveling machines: precision levelers, corrective levelers, and stretcher levelers.

- Q: How are steel coils processed at the steel service centers?

- Steel coils are processed at steel service centers through a series of steps to transform them into finished products that meet the specific requirements of customers. The process typically begins with the arrival of the steel coils at the service center. These coils are typically large and heavy, and may have been produced by a steel mill or imported from overseas. Once the steel coils are received, they are typically inspected for quality and any defects. This ensures that only high-quality coils are used in the production process. The coils are then stored in a warehouse until they are ready to be processed. Next, the steel coils are uncoiled. This involves unwinding the coil to create a flat sheet of steel. This can be done manually or using automated machines depending on the size and thickness of the coils. The uncoiled steel is then leveled to remove any residual stress and ensure a flat and consistent surface. After leveling, the steel sheets may undergo various processes depending on the desired end product. These processes can include cutting, shearing, slitting, and forming. Cutting and shearing involve cutting the steel sheets into specific sizes or shapes. Slitting involves cutting the steel into narrow strips, while forming involves bending or shaping the steel into the desired form. Once the desired processing operations are complete, the steel sheets are often treated with surface finishes to enhance their appearance or protect them from corrosion. These finishes can include painting, coating, or galvanizing. Finally, the processed steel sheets are inspected for quality again to ensure they meet the required specifications. They are then packaged and ready for shipment to customers, who may use them in various industries such as construction, automotive, or manufacturing. Overall, the processing of steel coils at steel service centers involves a combination of inspection, uncoiling, leveling, cutting/shearing/slitting/forming, surface finishing, quality control, and packaging. This process allows for the transformation of steel coils into finished products that are tailored to meet the specific needs and requirements of customers.

- Q: What are the challenges faced in the recycling of steel coils?

- One of the main challenges in recycling steel coils is the process of separating the different materials that may be attached to the coils, such as plastic or paper. These contaminants need to be removed before the steel can be recycled efficiently. Additionally, the size and weight of steel coils can pose logistical challenges in terms of transportation and storage. Lastly, ensuring that the recycled steel meets the required quality standards and specifications is another challenge faced in the recycling process.

- Q: What is the difference between steel coils and steel sheets?

- Steel coils and steel sheets differ primarily in their form and dimensions. Steel coils are long, continuous rolls of steel that have been wound up after being processed. They are typically produced in large quantities and are used in various industries, such as automotive and construction. Steel sheets, on the other hand, are flat pieces of steel that have been cut from coils or directly produced in a flat form. They come in different sizes and thicknesses, making them more suitable for specific applications such as roofing, cladding, or fabrication. In summary, while steel coils are the raw material for steel sheets, the main distinction is that coils are long rolls, while sheets are flat pieces of steel.

- Q: What are the dimensions of steel coils used in the agricultural structure industry?

- The dimensions of steel coils used in the agricultural structure industry can vary depending on the specific application and requirements. However, commonly used dimensions for steel coils in this industry range from 0.5mm to 3mm in thickness, and from 600mm to 1500mm in width. The length of the coils can also vary, but typically ranges from 1000mm to 3000mm. These dimensions allow for flexibility in the construction of agricultural structures such as barns, sheds, and storage facilities, while providing sufficient strength and durability. It is important to note that specific dimensions may vary depending on the manufacturer and the specific needs of the agricultural project.

- Q: How are steel coils used in the production of industrial boilers?

- Steel coils are used in the production of industrial boilers as they are fabricated into various components such as tubes, headers, and drums. These coils provide strength and durability to withstand high pressure and temperature conditions in boilers. Additionally, the coils are often used for heat exchange purposes, ensuring efficient transfer of thermal energy within the boiler system.

- Q: What are the different methods of edge trimming steel coils?

- There are several methods for edge trimming steel coils, including shearing, slitting, laser cutting, and milling. Each method has its own advantages and is chosen based on factors such as the desired precision, speed, and cost-effectiveness of the trimming process.

- Q: How are steel coils used in the production of metal shelving?

- Steel coils play a vital role in manufacturing metal shelving. Made from high-quality steel, these coils go through a series of manufacturing processes to transform them into sturdy and long-lasting shelves. To start, the steel coils are unwound and flattened to the desired thickness using a machine known as a slitter. This step ensures that the coils are uniform in size and thickness, which is crucial for producing consistent and dependable shelves. Next, the flattened steel is cut into specific lengths using a shear. These pieces are then sent to a press brake, where they are bent and shaped into the desired design for the shelves. The press brake applies pressure to the metal, allowing it to be folded or formed into various angles and shapes, such as shelves with raised edges or adjustable brackets. Once the shelves have been formed, they undergo a welding process to securely fuse any joints or seams. This welding process ensures the shelves' structural integrity, enabling them to support heavy loads and maintain their shape over time. After welding, the shelves go through surface treatment to improve their appearance and protect them from corrosion. This may involve cleaning, sandblasting, and painting. The surface treatment not only enhances the shelves' aesthetic appeal but also extends their lifespan by preventing rust and other forms of deterioration. Lastly, the shelves undergo a quality control inspection to ensure they meet the necessary standards. This involves checking for defects, measuring dimensions, and conducting load-bearing tests to ensure the shelves can withstand the intended weight capacity. In summary, steel coils are integral to the production of metal shelving. Through processes like unwinding, flattening, cutting, bending, welding, treating, and inspecting, these coils are transformed into strong, durable, and visually pleasing shelves suitable for various settings such as warehouses, retail stores, and homes.

- Q: I just want to know why is cold steel katana a very good sword?? How can you tell if a cold steel katana is good or not

- The only way to be sure about the steel in your sword is to take it to a university and have its components analyzed by the metals department. If there are high concentrations of carbon and iron and not much else, then you know the steel in your sword is of high quality and has been made well. There really is no other way short of bashing the sword against something else to determine how brittle it is or how strong it is. Ideally, you want a combination of both...high carbon steel on the outside to hold an edge, low carbon steel on the inside to give it strength and allow it to bend instead of break.

- Q: if someone wanted to melt cast steel or iron into small-relatively simple shapes such as rod-tapered rod-or etc... how would you go about melting the steel/iron what would the mold need to be made of?

- The other answers are correct. But don't attempt this unless you have lots of experience.

Send your message to us

Pre-painted Rolled Steel Coil for Construction Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords