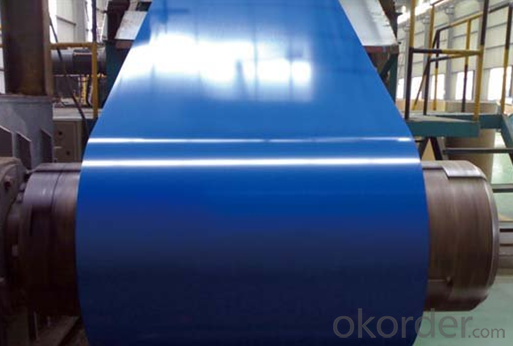

Pre-Painted Galvanized Steel Roofing Sheet/Hot Dipped Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

0.4mm-0.5mm Pre-Painted Galvanized Steel Roofing Sheet PPGI/Hot Dipped Galvanized Steel Coil

Product Description

1. Galvanized steel coil simple introduction:

Galvanized steel coil means that steel coils has gone through a chemical process

To keep it from corroding, so this protective metal, zinc layers, does not get rusty as easily. The coating also gives the steel a more durable, hard to scratch finish.

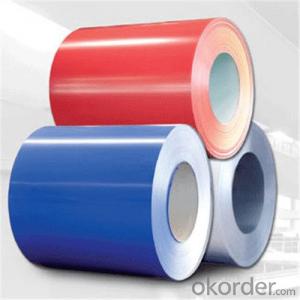

(1)Thickness:0.14-1.2mm

(2)Width:600-1250mm

(3)Material:SGCC,DX51D,S350GD,SPCC,CGCC

(4)Zn:40-275gsm

(5)Surface:oiled,chromated

(6)Application: Corrugated,Wall,Roofing,Structure and so on

2. Galvanized steel coil technical processing:

1)Uncoiled and sheared

2)Cleaned using a caustic solution, which can remove oil/grease, dirt, and paint

3)Entry looper to revised and then annealing furnace

4)Steel is dipped into the molten zinc bath

5)Cooled in a quench tank to reduce its temperature

6)Post treatment and crimper

3. Galvanized steel coil quality control:

Strict procurement process---skillful technical workers---final products inspection

(resistance to corrosion, salt spray test, exposure test, machinability, thermal resistance)

---standard packing

4. Galvanized steel coil advantages:

1)Zinc coating has good adhesion

2)Resistant to corrosive factors

3)High strength&quality

4)Strict quality control system

5)Standard export sea-worthy packing

5. Why choose us?

1).Advantages: We have two production line of PPGI and two lines for the galvanized steel coil, total yearly output is about 500000mt Also we have 56 professional salesperson from three international sales department, a group of technical engineers

And skillful quality control inspector.

2). Special technology support: We have two production line of pre-painted steel coil

And two lines for the galvanized steel coil, total yearly output is about 500000mt. In

Order to meet our customers new requirements, We also can manufacture the special

Products, such as Printed, Filmed, Pressed, Matte steel coil and the full hard G550

Galvanized steel and galvalume steel.

3). Conform the international quality standard: All products for export, according to the

International quality standard of Europe, Japan, Russia and America to produce.

Item: | Galvanized Steel Coils |

Material: | SGCC, SGCH, SPCC, SGCD, DX51D+Z, STO2Z,DX54D,DX51D |

Thickness: | 0.14mm-1.2mm |

Width: | 762-1250mm |

Length: | Coiled or as requested |

Surface: | Galvanized,oiled,chromated |

Application: | Industrial panels, roofing and siding for painting |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Zinc coating: | Z40-275g/m2 |

Surface Treatment: | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

Surface Structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

Coil Weight: | 3-10 ton per coil |

Payment term: | T/T,L/C |

Packing information: | Export standard package :bundled wooden box or be required; The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM |

Port: | Qingdao,Tianjin port |

Delivery time: | 15-20 days,after we received your deposit |

FAQ

1.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

2. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- Cold rolled steel coils are generally sprayed antirust oil, according to user requirements, light, medium, heavy oil 3 types. Nevertheless, if the oil is volatile or in a humid environment, the steel plate comes into contact with the water for a period of time, indicating that it is beginning to rust.

- Q: What are the challenges in the production of steel coils?

- The production of steel coils faces several challenges. Firstly, one of the major challenges is ensuring consistent quality throughout the production process. Steel coils need to have uniform thickness, width, and flatness. Achieving this consistently can be challenging due to variations in raw materials, equipment, and operating conditions. Another challenge is managing the high temperatures involved in the production process. Steel coils are produced by heating steel slabs or billets to extremely high temperatures and then rolling them into coils. Maintaining the required temperatures and ensuring proper cooling can be a complex task, as any deviations can lead to inconsistencies in the final product. Furthermore, the production of steel coils requires a significant amount of energy. The steel industry is one of the largest energy consumers globally. Reducing energy consumption while maintaining production efficiency is a constant challenge. Implementing energy-efficient technologies and optimizing processes are necessary to address this challenge. Moreover, the production of steel coils generates a considerable amount of waste and emissions. Steel manufacturing involves various chemical reactions and releases pollutants such as carbon dioxide, sulfur dioxide, and particulate matter. Managing and minimizing these emissions to comply with environmental regulations is a significant challenge for the industry. Additionally, steel coils are often produced in large quantities, requiring efficient logistics and transportation systems. Ensuring timely delivery and minimizing damage during transportation can be a challenge due to the weight and size of the coils. Lastly, the steel industry faces market challenges, including fluctuating prices of raw materials, competition from other materials, and global economic conditions. Adapting to market demands and maintaining competitiveness is crucial for the sustainable production of steel coils. Overall, the challenges in the production of steel coils include maintaining consistent quality, managing high temperatures, reducing energy consumption and emissions, optimizing logistics and transportation, and adapting to market dynamics. Addressing these challenges requires continuous innovation, technological advancements, and a focus on sustainability.

- Q: How are steel coils inspected for formability using forming tests?

- To assess their ability to be shaped into desired forms without any defects or failures, steel coils undergo inspections for formability through the use of forming tests. These tests are conducted to evaluate the mechanical properties of the material and determine if it is suitable for specific applications. Forming tests consist of subjecting the steel coil to different forming operations, such as bending, deep drawing, or stretch forming. The coil is typically cut into specific dimensions and then subjected to these operations using specialized equipment. The main objective is to replicate the actual forming process that the steel will experience in real-world applications. During the forming tests, several parameters are carefully monitored. These parameters include the amount of force or load applied, the rate of deformation, and the resulting strain or deformation experienced by the steel. Additionally, the response of the coil to these operations is observed, including any visible defects like cracks, fractures, or surface imperfections. By thoroughly analyzing the performance of the steel coil during the forming tests, various characteristics related to formability can be determined. These characteristics include the material's ability to resist deformation, its capacity to withstand strain without failure, and its tendency to exhibit defects under specific forming conditions. The results obtained from these tests provide valuable insights into the suitability of the steel coil for particular forming processes and applications. Furthermore, advanced techniques such as digital image correlation and strain analysis can be utilized to precisely measure and evaluate the distribution of strain across the surface of the steel coil. These techniques assist in identifying areas of the coil that experience higher strain and potential points of failure. In summary, the formability of steel coils is assessed through forming tests that simulate the actual forming processes they will undergo. These tests evaluate various formability characteristics, including the material's resistance to deformation and its likelihood of defects. The results obtained from these tests aid in determining the suitability of the steel coil for specific applications and guide the selection of appropriate forming parameters.

- Q: What is the standard width of steel coils?

- The standard width of steel coils can vary depending on the specific industry and application. However, in general, the standard width for steel coils ranges between 36 inches to 72 inches. The specific width will depend on factors such as the type of steel being used, the intended use of the coils, and the equipment used for processing and handling the coils. It is important to consult industry standards and specifications to determine the appropriate width for a particular steel coil application.

- Q: How are steel coils used in the manufacturing of construction formwork?

- Steel coils are used in the manufacturing of construction formwork to provide structural support and reinforcement. These coils are typically processed and formed into various shapes and sizes, which are then used as a framework or mold for pouring concrete. The strength and durability of steel coils make them ideal for withstanding the weight and pressure of the poured concrete, ensuring the stability and integrity of the formwork structure.

- Q: Molten steel changes to solid steel at its __________ point. Could you please fill in the blank? Thank you so much, it is greatly appreciated. I have been looking for the answer to this question for a long time, but I never understand what the websites are trying to say because I don't have that big of a vocabulary and don't know what they mean. I've seen things saying steel boiling point, steel melting point, and steel freezing point. I don't know what any of those mean, and they might be the answer. Please help me. Thank you.

- just like a melting point of ice and the boiling point of water, there are different points where something is converted into another form. such as icewatersteam. it's always the same thing and it's a physical change, but just in a different form. molten steel changes to solid steel at it's freezing point. or solid point. i'm not sure how you would word that. but it would not be melting or boiling point. hope that helped.

- Q: Can steel coils be coated with zinc-aluminum alloy?

- Yes, steel coils can be coated with zinc-aluminum alloy.

- Q: How do steel coils contribute to the energy infrastructure sector?

- Steel coils contribute to the energy infrastructure sector by serving as a crucial component in the construction and maintenance of power plants, oil and gas pipelines, and electrical transmission systems. These coils are used to manufacture various equipment and structures, such as turbines, generators, transformers, and transmission towers. Additionally, steel coils provide strength, durability, and corrosion resistance, ensuring the longevity and reliability of the energy infrastructure, ultimately supporting the efficient and uninterrupted supply of electricity, oil, and gas to meet the growing energy demands.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials.

- Q: Does aluminum or steel hold up better? We found a steel for 1/2 the price of aluminum, obviously its heavier but any other downsides? rust faster ect? also, does anybody know, in PA do you pay sales tax on trailers? and do dealers normally give you license plates to get the trailer home with? we live 3 hours away from the dealer so thats why i want all details :) would stink if i messed up!!

- I have a steel trailer. It's okay but I think next time I'll go for aluminum because mine is rusting, particularly on the tongue, so the hitch gets all frozen up. Drives me nuts. Yeah, you pay sales tax on trailers and the dealership SHOULD give you temporary plates to get home, just like they do on vehicles.

Send your message to us

Pre-Painted Galvanized Steel Roofing Sheet/Hot Dipped Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords