Hot Dipped Prepainted Galvanized Rolled Steel/Prepainted Cold Rolled Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

Product Description

CONTENTS | PRODUCT SPECIFICATION | |||||

| Commodity | Prepainted galvanized steel coil | |||||

| Base Metal | Cold rolled, Electro-galvanized base metal, Hot-dip zinc coated base metal, Hot dip Al-Zn steel sheet | |||||

Thickness | 0.16 TO 1.00 mm | |||||

| Width | 600 TO 1500 mm | |||||

| Coil ID | 508 / 610 mm | |||||

| Type | coil/sheet/strips | |||||

Delivery Time | 15-30days after we receive deposit | |||||

Substrate Hardness | Soft, medium,full hard | |||||

| Zinc Coating | Z 40-275 gsm, AZ 40-180 gsm or as customer requirements | |||||

| Types of top coating | PE, Silicon modified polyesters, High-durability polyester, polyvinylidene fluoride | |||||

Colours | As per RAL shades/customer requirements. | |||||

| Surface Finishes | Glossy and Matte | |||||

| Price: | US $600-800 / Metric Ton | |||||

| Slits | 37mm and above | |||||

| Standards | AISI, ASTM, BS, DIN, GB, JIS | |||||

| Transport | By bulk or container | |||||

| Packing | Standard packing or at buyer's requirement | |||||

Applications:

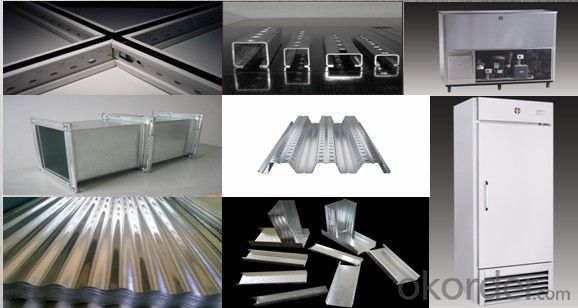

Pre-painted steel metal products are used in a vast array of applications including:

1.construction industry

2. household appliances

3.automotive

4.industrial applications

5.packaging

FAQ

What is the validity of your quotation?

Normally 2 days.

- Q: I thought it was STAINLESS STEEL! I have stainless steel can openers spatulas that are rusty. What's up with that? did you know that braces on people's teeth are made of stainless steel? That's why they call people metal-mouth. I used to have braces.

- You can rub the rust off with anything, from steel wool to Ajax. Although if you've previously used steel wool to clean it, that could be why it rusts. We had that problem manufacturing stainless steel railing and had to put it together on an aluminum table and polish welds with grinding wheels that never touched steel. What rusts are steel particles picked up on the stainless surface. Another possibility is that some stainless is more magnetic and usually also heat-treatable. It has just enough chrome in it to classify as stainless but can get minor surface rust. Not nearly as much as plain steel, though. Use a scouring powder like Zud or Barkeepers Friend and a cloth or sponge to polish if it's a sheetmetal surface rather than a bar grille, because these have oxalic acid and no bleach. They don't leave corrosive traces of chlorine behind. In fact, oxalic acid reduces rust to iron powder. Which is really neat if you need to clean a small rusty item--stir one of these powders into water, drop in the rusty piece and check it from time to time. Rinse off any abrasive powder, dry it well and oil it. When the rust is gone, it leaves a fine matte finish behind.

- Q: So i downloaded Broken Steel DLC for Fallout 3 for the 360. My guy is on the level where you have to activate the purifier and when i beat it. It was the normal ending that brought me back to the main menu. My friend said you have to find some guy to talk to but i don't think thats it. Please Help. P.S. i never got and conformation in-game about the download but its under the download sub menu at the main menu.

- after you've downloaded broken steel, while playing in game you should get a message saying, broken steel loaded, then you can make your way to the purifier and finish of the col. and activate it, after-wards you will have to sit through the end movie, which I felt was longer than the original, then the broken steel part will start, which I wont ruin. If your still having problems, go into your DLC and delete broken steel, and re-install it.

- Q: Can you suggest me names of sites which aids in construction of Pre Fabricated Steel Buildings.

- A word of caution, there are many bad steel building contractors out there. Stay with reputable brands such as Butler, Behlen, and Whirlwind. A broker such as Heritage will get you good results but I have heard horror stories about a lot of steel building brokers.

- Q: What is the process of pickling and oiling steel coils?

- The process of pickling and oiling steel coils involves several steps to ensure the quality and protection of the steel. Firstly, pickling is the process of removing impurities and scale from the surface of the steel coil. This is typically done by immersing the coil in an acid bath, such as hydrochloric acid or sulfuric acid, which helps to dissolve any oxides, rust, or other contaminants present on the surface. This step is crucial as it prepares the steel for further processing and prevents any potential defects or corrosion. After pickling, the steel coils are rinsed with water to remove any residual acid and then dried. Once the coils are clean and dry, they are then coated with a layer of oil to provide temporary corrosion protection and lubrication during subsequent handling and transport. The oil coating helps to prevent the steel from rusting or oxidizing before it is further processed or used in various applications. The oiling process can be done in several ways. One common method is by applying the oil using a roller or brush, ensuring that the entire surface of the coil is evenly coated. Alternatively, the coils can be passed through a bath or spray chamber where the oil is applied. The type of oil used can vary depending on the specific requirements of the steel and its intended use. Some common oils include mineral oil, synthetic oils, or specialized rust-preventive coatings. Once the oiling process is complete, the steel coils are typically stacked, wrapped, or packaged for storage or transportation. It is important to handle the coils carefully to avoid damaging the oil coating and compromising the corrosion protection. Overall, pickling and oiling steel coils are essential steps in the steel manufacturing process to ensure the quality, cleanliness, and protection of the steel, ultimately extending its lifespan and enhancing its performance in various applications.

- Q: How are steel coils used in the automotive industry?

- Steel coils are used in the automotive industry to manufacture various components such as car bodies, frames, and structural parts. The coils are first processed by being uncoiled, flattened, and then cut into the required shapes. These steel components provide strength, durability, and rigidity to vehicles, ensuring safety and structural integrity.

- Q: What materials are used to make steel coils?

- Steel coils consist primarily of steel, an alloy primarily composed of iron and carbon. The choice of steel type for coil production depends on the desired properties and applications. Carbon steel is typically the preferred option due to its strength, durability, and versatility. Additional alloying elements, like manganese, silicon, nickel, or chromium, may be incorporated to enhance specific steel characteristics or properties. To produce steel coils, the raw materials are melted, the molten steel is refined, and specialized equipment and processes are employed to shape it into coils.

- Q: Can you weld copper or brass to steel?

- GTAW,Weld Copper to steel, RN-60. Silver Braze Copper to Steel, Grade 4 Silver.

- Q: How are steel coils inspected for defects?

- To ensure the quality of steel coils meets required standards, various methods are used to inspect them for defects. Visual inspection is a common method, where trained inspectors examine the coil's surface for visible defects like cracks, scratches, or dents. This can be done through direct observation or with the help of magnifying tools. Another method is magnetic particle inspection, which detects surface and near-surface defects like cracks or voids. Here, a magnetic field is applied to the coil, and magnetic powder is spread on the surface. If any defects are present, the powder will be drawn to them, making them visible to the inspector. Ultrasonic testing is also commonly employed to inspect steel coils for defects. It involves transmitting high-frequency sound waves into the coil and analyzing the reflected waves. Any deviations in the sound waves can indicate the presence of defects like cracks or voids within the coil. Eddy current testing is another method used to detect defects in steel coils. It works by using electromagnetic induction to generate eddy currents within the coil. Any changes in these currents caused by defects in the material are detected and analyzed by the inspector. Finally, in some cases, destructive testing is performed on steel coils. This involves taking a sample from the coil and subjecting it to tests such as tension or bend testing. These tests evaluate the mechanical properties of the steel and indirectly indicate the presence of defects. Overall, a combination of visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and potentially destructive testing is used to inspect steel coils for defects. These methods ensure that any defects are identified and addressed, guaranteeing the delivery of high-quality steel coils to customers.

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with zinc-nickel alloy.

- Q: Can steel coils be used in structural applications?

- Yes, steel coils can be used in structural applications. They are often used in the construction industry for various structural components such as beams, columns, and trusses. Steel coils provide strength, durability, and flexibility, making them suitable for supporting heavy loads and withstanding various environmental conditions.

Send your message to us

Hot Dipped Prepainted Galvanized Rolled Steel/Prepainted Cold Rolled Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords