Pre-painted Galvanized / Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

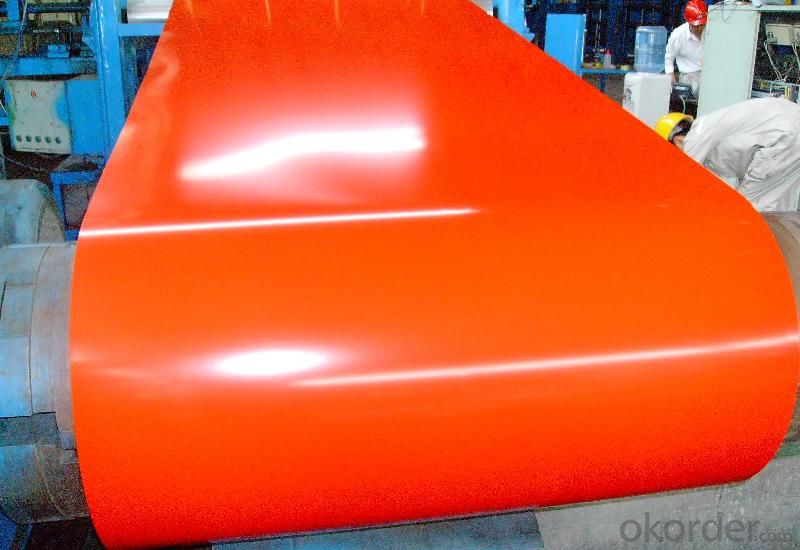

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Surface finish: with or without protect film

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel products across various sectors such as construction, automotive, and infrastructure is contributing to the growth of the industry. Steel coils are widely used in these sectors for manufacturing various products such as automobiles, buildings, bridges, and pipelines. Secondly, rapid industrialization and urbanization in emerging economies are fueling the growth of the steel coil industry. Countries like China, India, and Brazil are witnessing significant infrastructure development and construction activities, which require a large amount of steel coils for various applications. Additionally, technological advancements in the manufacturing process and the use of advanced steel alloys are driving the growth of the industry. These advancements have led to the production of high-quality steel coils that offer better strength, durability, and corrosion resistance. Moreover, the growing focus on sustainable and eco-friendly practices is also driving the growth of the steel coil industry. Steel is a highly recyclable material, and the increasing awareness about the environmental benefits of using steel is boosting its demand. Furthermore, favorable government policies and initiatives to promote domestic steel production and reduce imports are also contributing to the growth of the industry. Governments are implementing measures such as import tariffs and subsidies to support local steel manufacturers, which is driving the demand for steel coils. In conclusion, the factors driving the growth of the steel coil industry include increasing demand from various sectors, rapid industrialization, technological advancements, environmental awareness, and supportive government policies.

- Q: How are steel coils coated for added protection?

- Steel coils are coated for added protection using a process called coil coating. This process involves the application of a protective layer onto the surface of the steel coil to enhance its durability and resistance to corrosion. There are various methods used to coat steel coils, but the most common one is the continuous coil coating process. In this process, the steel coil is unwound and cleaned thoroughly to remove any contaminants or impurities from the surface. This ensures proper adhesion of the coating material. Once the steel coil is cleaned, it is then pre-treated to enhance its surface properties. This pre-treatment typically involves applying a chemical solution or a conversion coating to the surface of the coil. The purpose of this step is to create a receptive surface for the coating material and enhance its adhesion. After the pre-treatment, the steel coil is coated with a protective layer. This coating material can be a liquid paint, a powder coating, or sometimes a combination of both. The coating is applied uniformly onto the surface of the coil using various techniques, such as roll coating, spray coating, or electrostatic coating. Once the coating is applied, the steel coil is cured or dried using heat or sometimes ultraviolet light. This curing process ensures that the coating material forms a strong bond with the steel surface and achieves the desired protective properties. The coated steel coil is then inspected for quality control measures, such as thickness, adhesion, and appearance. If it meets the required specifications, it is further processed, which may involve cutting, slitting, or forming into the desired shape or size. Overall, the process of coating steel coils for added protection involves thorough cleaning, pre-treatment, application of a protective coating, curing, and quality control. This ensures that the steel coils possess excellent resistance to corrosion, abrasion, and other environmental factors, making them suitable for a wide range of applications in various industries.

- Q: basically all the info you can find about s1 tool steel i found a bunch about annealing, and hardening, tinsel strength and stuff like that but i need MORE!!!!!

- S1 Tool Steel

- Q: How are steel coils made?

- Steel coils are made through a process called hot rolling, where a large slab of steel is heated and passed through a series of rolling mills to gradually reduce its thickness and shape it into a coil.

- Q: How are steel coils used in the production of heating systems?

- The production of heating systems relies on the utilization of steel coils in various ways. One primary application of steel coils in heating systems involves their incorporation in the construction of heat exchangers. Heat exchangers serve a vital purpose in the transfer of heat from one medium to another within the heating system. Typically, the steel coils are shaped into tubes or fins, which maximize the surface area for optimal heat transfer. In a typical heating system setup, the steel coils allow hot gases or liquids to pass through them, while another medium, such as air or water, flows over or through the coils. This arrangement facilitates the efficient transfer of heat energy from the hotter medium to the cooler one, effectively heating the air or water for distribution throughout the heating system. Steel coils are also employed in the production of radiant heating panels or floor heating systems in heating applications. In these instances, the steel coils are usually embedded within a panel or positioned beneath the flooring. When electricity or hot water passes through the coils, they heat up and emit heat to the surrounding environment. This particular heating system type boasts high efficiency and ensures a comfortable and evenly distributed heat output. Moreover, steel coils are integral components of heating systems such as boilers, furnaces, and heat pumps. These heating system units often require the use of steel coils due to their excellent heat transfer capabilities and durability. The integration of steel coils into the design of these units guarantees efficient and reliable heat generation and distribution. In summary, steel coils play a critical role in the production of heating systems as they enable efficient heat transfer, provide durability, and facilitate the generation and distribution of heat.

- Q: What are common uses for steel coils?

- Common uses for steel coils include manufacturing automobiles, construction materials, appliances, pipes, and various industrial applications such as manufacturing machinery and equipment.

- Q: How are steel coils used in the manufacturing of automotive components?

- Steel coils are used in the manufacturing of automotive components by being processed and shaped into various parts such as body panels, frames, suspension components, and engine parts. The coils are typically cut, formed, and welded to create the desired shape and strength required for each specific component. The use of steel coils allows for the production of durable, strong, and cost-effective automotive parts that meet the industry's high standards for safety and performance.

- Q: i need the same kind of body jewelry they use in the piercing shop but when i go to order them they say stainless steel, not surgical steel, and i have REALLY sensitive skin so i need to be sure, whats the difference?

- This Site Might Help You. RE: is stainless steel and surgical steel the same? i need the same kind of body jewelry they use in the piercing shop but when i go to order them they say stainless steel, not surgical steel, and i have REALLY sensitive skin so i need to be sure, whats the difference?

- Q: What are the different types of steel coil packaging systems?

- There are several types of steel coil packaging systems available, including horizontal coil packaging machines, vertical coil packaging machines, and coil wrapping machines. Each system is designed to securely package steel coils for transportation and storage, ensuring their protection from damage and corrosion.

- Q: I'm quite confused...i watched all of steel angel kurumi (the 28 episodes) and then continued to steel angel kurumi zero. it was an entire different story line with only the steel angels being the same. the world is different the guys are different, and there is a new character. Even the humor is gone. its like a whole different series. So what gives, what is the relationship between them?

- Steel Angel Zero is an OVA (Original Video Animation), a very short animation that went straight to DVD. It probably was written because Kurumi was so popular, and the producer wanted to check the waters for whether they should make a second season. It's pretty hard to keep track of what anime is which, especially in the more popular series. If you think Zero is worth zero, try Steel Angel Kurumi 2 (anime, 12 episodes), and Steel Angel Kurumi Encore (OVA, 4 episodes) as well.

Send your message to us

Pre-painted Galvanized / Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords