Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

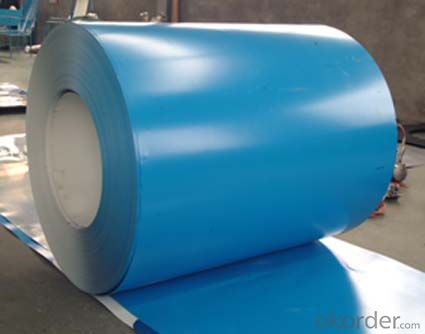

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different steel coil surface treatments?

- Some of the different steel coil surface treatments include galvanizing, painting, powder coating, and oiled finishes.

- Q: What are the different types of steel coil handling equipment used during processing?

- There are several types of steel coil handling equipment used during processing, including coil cars, coil upenders, coil tilters, coil transfer cars, coil grabbers, coil lifters, and coil reels. These machines are designed to efficiently handle and maneuver steel coils of various sizes and weights, ensuring safe and smooth operations during the processing stages.

- Q: What are the different methods of coil blanking for irregular shapes?

- Coil blanking for irregular shapes can be achieved through various methods. Among these methods, one commonly employed technique is laser blanking. By utilizing a high-powered laser, the shape is directly cut from the coil with exceptional precision. This method proves especially effective for intricate shapes, minimizing wastage. Another approach is water jet blanking, where a forceful stream of water mixed with abrasive particles is employed to cut the shape from the coil. Water jet blanking is particularly suitable for thicker materials or situations where heat sensitivity is a concern. Additionally, die blanking involves the utilization of a die to stamp out the desired shape from the coil. This method is frequently applied in large-scale production runs and can be automated for improved efficiency. Lastly, plasma blanking utilizes a plasma torch to cut the shape from the coil. It is commonly employed for thicker materials or situations requiring high cutting speeds. The choice of coil blanking method for irregular shapes is dependent on factors such as material thickness, shape complexity, production volume, and desired precision. Each method possesses its own advantages and limitations, necessitating careful selection to achieve optimal results.

- Q: What are the different coil coatings available for steel coils?

- There are several different coil coatings available for steel coils, each offering unique benefits and characteristics. Here are some of the most common coil coatings used in the industry: 1. Polyester: Polyester coil coatings are widely used due to their excellent durability and resistance to fade, scratch, and corrosion. They provide good UV resistance and are available in a wide range of colors. 2. Polyvinylidene fluoride (PVDF): PVDF coatings are known for their exceptional resistance to weathering and UV radiation. They offer excellent color retention, gloss retention, and overall durability, making them suitable for outdoor applications. 3. Polyurethane: Polyurethane coil coatings provide a high level of abrasion resistance and flexibility. They offer excellent chemical resistance and are often used in industries such as automotive and appliances. 4. Silicone modified polyester (SMP): SMP coatings offer good resistance to fading, chalking, and cracking. They provide excellent weather resistance and are commonly used in architectural applications. 5. Epoxy: Epoxy coil coatings are known for their excellent adhesion and chemical resistance. They are often used in demanding environments such as automotive parts and appliances. 6. Plastisol: Plastisol coatings are PVC-based and provide a thick, flexible film on the surface of the steel coil. They offer excellent corrosion resistance and are commonly used in the construction industry. These are just a few examples of the different coil coatings available for steel coils. The choice of coating depends on factors such as the intended application, environmental conditions, desired appearance, and required performance characteristics. Consulting with a coil coating expert can help determine the most suitable coating for a specific project.

- Q: How are steel coils used in the manufacturing of industrial machinery?

- Steel coils are used in the manufacturing of industrial machinery as raw material for various components, such as frames, brackets, and supports. The coils are processed by cutting, bending, and shaping to create specific parts that provide stability, strength, and structure to the machinery. Additionally, steel coils are often used for creating gears, shafts, and other moving parts that require high durability and resistance to wear and tear.

- Q: How are steel coils used in the production of prefabricated buildings?

- Steel coils are used in the production of prefabricated buildings as they are flattened and cut into specific sizes to serve as the structural framework. These coils are typically formed into beams, columns, and other essential components, which are then assembled and interconnected to create the building's frame. The strength and durability of steel make it an ideal material for prefabricated structures, ensuring the safety and stability of the buildings.

- Q: What are the typical dimensions of a steel coil?

- The typical dimensions of a steel coil can vary depending on its purpose and industry standards. However, common dimensions for steel coils include a width ranging from 600mm to 2000mm, a coil diameter of around 1000mm to 2000mm, and a weight capacity ranging from a few tons to several dozen tons.

- Q: How are defects in steel coils repaired?

- Defects in steel coils can be repaired through several methods depending on the type and extent of the defect. One common approach is known as welding repair, which involves using specialized welding techniques to fix the defect. This method is typically used for minor defects such as cracks or small holes in the coil. The damaged area is cleaned, prepped, and then welded using appropriate welding rods or wires to ensure a strong and durable repair. For more severe defects, such as large holes or significant damage to the coil, a patching technique may be employed. This involves cutting out the damaged section and replacing it with a new piece of steel. The patch is usually welded to the intact areas of the coil, ensuring a secure and seamless repair. In some cases, defects can also be addressed through grinding or sanding techniques. This is often used for surface defects like scratches or blemishes that do not compromise the structural integrity of the coil. Grinding or sanding the affected area smooths out the defect, improving the appearance and preventing further damage. It is worth noting that the repair method chosen depends on factors such as the specific defect, the material of the coil, and the intended application of the steel. The repair process may also involve additional steps such as heat treatment or surface finishing to restore the coil to its original condition. Overall, repairing defects in steel coils requires the expertise of skilled technicians and specialized equipment. It is crucial to address these defects promptly to prevent further damage and ensure the coil's performance and longevity.

- Q: How is the demand for steel coils influenced by the construction sector?

- The demand for steel coils is heavily influenced by the construction sector. As construction activities increase, so does the demand for steel coils as they are essential for various construction applications such as structural components, roofing, and reinforcing materials. Conversely, when construction activities decline, the demand for steel coils also decreases. Therefore, the construction sector plays a crucial role in driving the demand for steel coils.

- Q: Can steel coils be used in the production of furniture?

- Yes, steel coils can be used in the production of furniture. Steel coils can be used to create sturdy frames for furniture such as chairs and sofas. The coils can be shaped and welded together to provide support and durability to the furniture.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords