Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price in Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• High strength

• Good capable of decoration

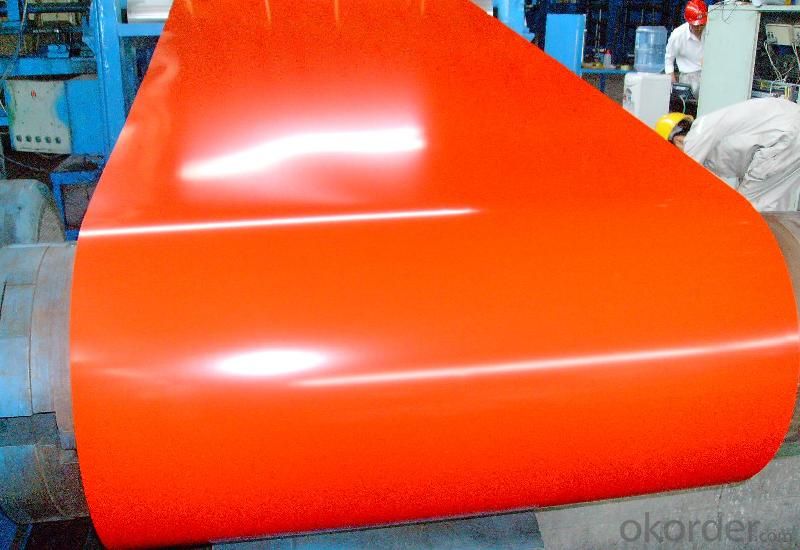

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

6.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment primarily for their strength, durability, and corrosion resistance. These coils are utilized to manufacture various components such as pipes, valves, fittings, and storage tanks that are required in the exploration, drilling, and transportation of oil and gas.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork to form the main structure of the ducts. The steel coils are processed and shaped into specific sizes and dimensions, allowing them to be easily fabricated into duct sections. These coils provide strength and durability to the ductwork, ensuring it can withstand the high pressures and temperatures involved in HVAC systems.

- Q: How are steel coils inspected for flatness variations?

- Steel coils are inspected for flatness variations using various methods such as visual inspection, measurement techniques, and automated systems. Visual inspection involves trained personnel visually inspecting the coil's surface for any irregularities or deviations from flatness. Measurement techniques involve using precision instruments such as straight edges, feeler gauges, or laser sensors to measure the flatness at different points along the coil's length. Automated systems use advanced technologies like laser scanning or optical sensors to quickly and accurately detect any flatness variations in the steel coils. These inspections help ensure that the coils meet the required flatness specifications and quality standards.

- Q: How are steel coils handled during transportation to prevent damage?

- Steel coils are typically handled during transportation by using specialized equipment such as cranes or forklifts with padded forks. They are secured with steel bands or other restraints to prevent movement and damage. Additionally, they are usually loaded onto flatbed trucks or shipping containers with proper cushioning and support to minimize the risk of impact or deformation during transit.

- Q: What are the different types of steel coil surface treatments for outdoor applications?

- There are several different types of steel coil surface treatments that are commonly used for outdoor applications. These treatments are applied to the steel to enhance its durability, corrosion resistance, and appearance. Some of the most commonly used surface treatments for outdoor applications include: 1. Galvanized: Galvanization is a process where a layer of zinc is applied to the steel surface. This treatment provides excellent corrosion resistance, making it ideal for outdoor applications. Galvanized steel coils have a shiny, silver appearance. 2. Galvalume: Galvalume is a combination of aluminum and zinc, which is applied to the steel surface. This treatment provides superior corrosion resistance compared to galvanized steel. Galvalume steel coils have a duller, matte finish. 3. Painted: Steel coils can be painted with a variety of coatings to enhance their appearance and protect against corrosion. The paint can be applied in a single or multiple layers, depending on the desired level of protection. Painted steel coils are available in a wide range of colors and finishes. 4. Powder Coated: Powder coating is a type of paint coating that is applied as a powder and then cured under heat. This treatment creates a durable and long-lasting finish. Powder coated steel coils are resistant to chipping, scratching, and fading, making them suitable for outdoor applications. 5. Organic Coated: Organic coatings, such as PVC or PVDF, are applied to steel coils to provide additional protection against corrosion and weathering. These coatings are typically used in architectural applications where aesthetics and durability are important. These different types of steel coil surface treatments offer various levels of protection and aesthetic options for outdoor applications. The choice of treatment depends on factors such as the intended use, environmental conditions, and desired appearance.

- Q: i need a company that sells strong steel doors because my neighbors apartment was broken into. I need a strong steel door for the outside of the home, where you first enter. please list places in the US, or in NY.

- You okorder

- Q: I have a job where I'm required to wear ANSI certified steel toed boots or shoes(so long as its ANSI). Thing is, I'm a vegan. I do NOT want to buy leather, and I will go to great lengths to buy a non leather shoe/boot I can wear on the job! I AM currently borrowing my dad's leather ANSI boots, but would very much love to be able to rock a pair of cruelty free boots/shoes on the job!It does not have to be certified vegan just all man-made materials and no leather/sued and other such stuff where animals have to die. It would make me no better than the massive slaughterhouse industries and such. Valueing money of ver live/morals. I don't want one of the first things I need to do in my manufacturing job is compromising my morals. :3So if you know of an ANSI vegan friendly boot brand PLEASE TELL ME! *gets on knees begging*Money isn't really an option for me, I'll just continue borrowing my dad's boots till I save up enough!Thanks in advance! :D

- Vegan okorder /... I don't know if they're ANSI shoes, so you might want to ask.

- Q: We are going to build a house with a steel frame.Someone told me today that these houses have problems with humidity.Is that true?Please tell me all you know..

- The humidity is not at all related to the framework of any house. Galvanized steel has become popular especially in commercial applications because lumber costs are increasing exponentially. Consider that any home built should be adequately ventilated, insulated, and certainly constructed. Consider where the house is,,,IE: Near water; in a tropical setting; prone to being in an area that floods; or gets a lot of rain. The exterior and interior of a steel framed house is the same as a wood frame. I'd go with block personally and steel roof rafters and joists. Once the house is built, adequate ventilating, heating, and/or air conditioning should be accomplished to keep the humidity levels tolerable, and not effect mold, mildew, excesssive heat, etc. Rev. Steven

- Q: How do steel coils compare to other materials?

- Steel coils have several advantages over other materials. Firstly, steel is incredibly strong and durable, making it ideal for heavy-duty applications. Additionally, steel coils have excellent heat and corrosion resistance, making them suitable for a wide range of environments. Steel also offers better conductivity and magnetic properties compared to other materials. Overall, steel coils are highly versatile and provide superior performance in various industries.

- Q: okay i got some questions of the steel plow.1st - who inveneted it? where and when?2nd - how did it work? what is it used for? what is it made of? how is it produced?okay guys thank you very much. remember best answer gets best answer 10 points!

- If you're willing to substitute the word iron for steel (steel came a good bit later in history), the Girard plow from the 1300's in Belgium would be the first example known. It's named after the guy who invented it (Girard). How did it work? Like any other plow! You drag it along and it makes a trench of sorts in the ground! It was used for agricultural purposes. As for how it was produced, you need to look up the history of the Iron Age to understand how they started to use iron back in about 1200BC to make tools.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price in Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords