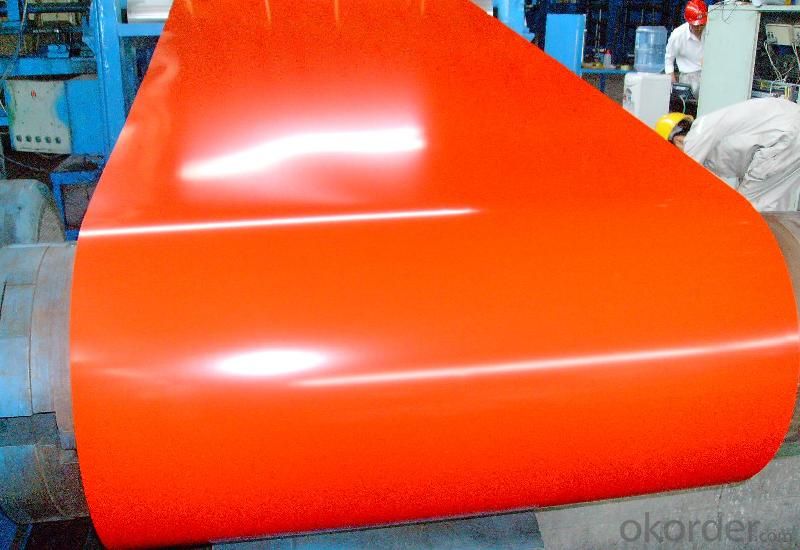

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price in Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• High strength

• Good capable of decoration

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

6.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

- Q: All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- Stainless Steel Appliance Cleaning Stainless steel kitchen appliances look best when they're clean and shiny. To clean tough stains and cooking grease, and give them a dazzling shine, try the same detergent you would use when washing the dishes. One formulated to cut grease works especially well.This also works well for general kitchen cleaning.Waterless hand soap also works great as a polish, simply rub on, and polish - no rinsing.=)

- Q: How are steel coils used in various industries?

- Steel coils are used in various industries for a wide range of applications. In the automotive industry, they are used to manufacture car bodies, chassis, and parts. In construction, steel coils are used in the production of beams, columns, and roofing materials. They are also utilized in the manufacturing of appliances, electrical equipment, and machinery. Additionally, steel coils are essential in the production of pipes, tubes, and other structural components. Overall, steel coils play a crucial role in providing strength, durability, and versatility to multiple industries.

- Q: I'm writing a story, and trying to find out how hot it needs to be for steel to turn into a gas.

- Steel is to broad. There are many types of steel with different melting/boiling points. Iron* has a boiling point of 5182 °F and a Heat of vaporization of 340 kJ·mol?1. iron is the main ingredient of steel, along with carbon and other various elements.

- Q: What are the different types of steel coil handling systems?

- There are several types of steel coil handling systems, including cradle systems, C-hook systems, coil grab systems, and coil transfer cars. These systems are designed to safely and efficiently handle steel coils of various sizes and weights in manufacturing and storage facilities.

- Q: What are the dimensions of a steel coil?

- The dimensions of a steel coil can vary depending on several factors such as the intended use, manufacturer specifications, and industry standards. However, common dimensions for steel coils typically include variations in width, thickness, and weight.

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- Pedal steel guitars are a challenge to learn but they're a great instrument. More, even a starter pedal steel is going to run you $800 or so. Elderly Instruments in Lansing, Michigan sells a Carter brand starter pedal steel for $795 which is about as low as I've seen new ones. It has 3 foot pedals and 4 knee levers so it's nicely equipped. From northern Indiana it's not that far I would think. Good luck.

- Q: What are the common methods of slitting steel coils?

- There are several common methods of slitting steel coils, each with its own advantages and applications. 1. Rotary Shear Slitting: This method involves using rotary cutting knives to slit the steel coil. The coil is fed through the rotary shear machine, and the knives make simultaneous cuts along the length of the coil. Rotary shear slitting is known for its high-speed operation and ability to handle thicker gauge materials. 2. Loop Slitting: Loop slitting is a method where the steel coil is fed into a looping pit, creating a loop of material. The loop is then pulled through a set of knives that make the slits. This method is commonly used for thin gauge materials and provides precise cuts with minimal burr. 3. Drag Slitting: In drag slitting, the steel coil is fed through a set of driven rolls or drag pads, which help to maintain tension on the material. The coil is then guided through circular knives that make the slits. Drag slitting is suitable for various gauges of steel and offers good accuracy and edge quality. 4. Crush Slitting: Crush slitting involves passing the steel coil through a set of rolls, where one roll is rubber-covered and the other is hard. The rubber roll compresses the material against the hard roll, creating the slits. This method is commonly used for thin gauge or delicate materials as it minimizes the risk of edge damage. 5. Laser Slitting: Laser slitting utilizes a high-powered laser beam to make precise cuts on the steel coil. This method is highly accurate and allows for complex slitting patterns and narrow width cuts. Laser slitting is often used for high-end applications that require superior edge quality. Each of these methods has its own advantages and is chosen based on factors such as material thickness, desired edge quality, production speed, and cost considerations. It is important to carefully select the appropriate slitting method to ensure the desired outcome and efficiency in steel coil processing.

- Q: i am looking for an exact process of how to forge damascus steel.any tips or pointers and web sites or tutoreals will be helpfull.

- hand made folding knife English tip, blade of Damascus metallic sort Rose, 2,5mm thickness, no liners, teja spring embellished by using metallic report and billet surrounded of chrome metallic. A Damascus blade knife is characterised by using a wavy, mottled visual allure on the blade that’s led to by using the approach used to shape the metallic. the technique of transforming into Damascus metallic is derived from a centuries-previous forging technique used to create blades that grew to become very just about mythical of their attractiveness for power and sharpness it exchange into reported a Damascus knife ought to shrink with the aid of a rifle barrel to boot as with the aid of a hair falling on the blade.

- Q: What are the common methods of recoiling steel coils?

- Manufacturers and customers have various options when it comes to recoiling steel coils. One frequently used method is slitting, which employs rotating circular blades to cut a wide steel coil into narrower strips. This results in multiple smaller coils with desired widths. Slitting is commonly employed to create coils of different sizes for diverse applications. Another technique is known as cut-to-length (CTL) recoiling, where the steel coil is cut into specific lengths according to the customer's requirements. This involves passing the coil through a straightening and leveling machine, followed by a flying shear that cuts the steel into the desired lengths. CTL recoiling is particularly useful in industries that demand precise and uniform steel lengths, such as construction or automotive. Furthermore, there is a method called coil-to-coil recoiling. This process involves rewinding the steel coil onto a new coil with the desired dimensions and properties. Coil-to-coil recoiling is typically utilized when the original coil needs resizing, reconditioning, or rerolling for further processing or transportation purposes. Specialized recoiling machines ensure proper tension, alignment, and winding of the steel coil onto the new coil. In conclusion, the recoiling of steel coils can be accomplished through various methods, including slitting, cut-to-length recoiling, and coil-to-coil recoiling. Each method offers its own advantages and is chosen based on factors such as required coil dimensions, precision, efficiency, and the specific needs of the industry or customer.

- Q: How are steel coils used in the manufacturing of tools?

- Steel coils are used in the manufacturing of tools as they provide a strong and durable material that can be shaped and formed into various tool components. These coils are typically cut, bent, and shaped to create the desired tool design, and then further processed and treated to enhance their strength and performance. Additionally, steel coils are often used for tool handles, as they provide a sturdy grip and long-lasting durability.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price in Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords