Pre-Painted Galvanized/Aluzinc Steel Coil Workability Durability

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

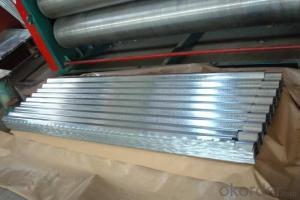

1. Pre-Painted Galvanized/Aluzinc Steel Coil Workability Durability

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Excellent heat resistance performance

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- if a magnet sticks to it that means it's a cheaper metal coated with stainless steel. if it's an appliance you're buying, look on the reciept. real stainless steel will actually say it. the coated stuff will just say stainless leaving out the steel.

- Q: What are the different types of steel alloys used in coil manufacturing?

- There are several types of steel alloys commonly used in coil manufacturing, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. Carbon steel is the most common and affordable option, offering good strength and durability. Stainless steel is corrosion resistant and often used in applications where hygiene or aesthetics are important. HSLA steel provides high strength and improved formability, making it suitable for demanding applications such as automotive parts.

- Q: What are the common methods of slitting steel coils?

- The common methods of slitting steel coils include rotary slitting, multiblade slitting, and shearing.

- Q: Steel Strings on your guitar or nylons? Why?

- There is no OR about it. You CANNOT use steel strings on a nylon string guitar because the increased tension will actually warp the top of the guitar and eventually pull the bridge right off! (I have seen it happen several times!) Although it is possible to put nylon strings on a steel string guitar it is not recommended. Nylon strings do not have as much tension as a steel string guitar is designed for. Steel string guitar necks are actually designed with a bit of back bow to compensate for the high tension of steel strings. Nylon strings have a much lower tension which could cause the neck of a steel string to settle slightly, which could actually cause the strings to fret out. It is not common, but it does happen. So keep your guitars happy and only string them with the proper strings.

- Q: Alright...Please tell me what I can and can't buy for Steel Legion in detail(Much Detail please)Ogryns.Las canons.The problem I'm having is that they don't have steel Legion Uniform..does it matter?1.I also heard that you can't use Commisar Yarrick.(So what could I use?)2.What are my Hq choices,Fast attack,Heavy Support,Elite etc.3.Steel Legion has a Commisar....(Do I buy one for each squad of Steel Legion or one?)Please in detail what should I buy...I don't have the codex yet but will soon!!4.I also heard that if I get Steel Legion I need a transport for everything?(Is this true?)5.Please be detail on what i can't and can buy!!(Please like HQ Squad leader,Sargent)

- here are a couple of things about the steel legion. you should have a lot of mechanized units, have chimaras for rvery squad if posible, artillery fire helps a hell of a lot. also sentinals and leman russes and hell hounds also help. if in apocolypse, use banblades and titans. storm trooper squads should be your base squadrons. put them in chimeras and get near the action, drop 'em off and rapid fire like CRAZY!!! the steel legion loves heavy weapons so remember to get some heavy weapons platforms. there favourite weapons are grenade and missle launchers. there is also an officer you can buy with a power sword with the steel legion look. steel legion are big xeno hunters. because commisar is a ork killer you should be allowed to field him. ratling/ sniper squads also help and if you can get a vindicare assassin that is very useful.

- Q: What are the different methods of joining steel coils?

- There are several methods used for joining steel coils, including welding, brazing, soldering, and mechanical fastening. Welding is the most common method, which involves melting the edges of the coils and fusing them together. Brazing and soldering involve using a filler metal with a lower melting point to join the coils. Mechanical fastening methods include using bolts, screws, or clips to connect the coils together. Each method has its own advantages and is chosen based on the specific requirements and constraints of the application.

- Q: What are the different methods of surface cleaning for steel coils?

- Some of the different methods of surface cleaning for steel coils include mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials, such as brushes or sandpaper, to physically remove dirt, rust, or other contaminants from the surface of the steel coils. Chemical cleaning involves the use of specific cleaning agents or solvents to dissolve or loosen dirt and contaminants from the surface. High-pressure water cleaning utilizes a powerful jet of water to remove dirt and debris from the steel coils. These methods can be used individually or in combination depending on the specific cleaning requirements and condition of the steel coils.

- Q: What are the challenges in storing and handling steel coils?

- Storing and handling steel coils present several challenges, including their sheer weight and size, which can make transportation and storage difficult. The coils need to be stored in a way that prevents damage and deformation, as steel coils are susceptible to rust, corrosion, and scratching. Additionally, ensuring proper ventilation and moisture control is crucial to prevent the growth of mold or moisture-related damage. Safety precautions must also be taken during handling and transportation to avoid accidents or injuries.

- Q: How are steel coils used in the manufacturing of automotive fuel tanks?

- Steel coils are used in the manufacturing of automotive fuel tanks as they provide strength, durability, and resistance to corrosion. These coils are formed and welded into shape to create the fuel tank, ensuring it can withstand the pressure and vibrations associated with storing and transporting fuel safely.

- Q: How are steel coils tested for dimensional accuracy?

- Steel coils are tested for dimensional accuracy through various methods such as measuring their width, length, thickness, and diameter using specialized tools like calipers, micrometers, or laser measurement systems. These measurements are compared against the specified tolerances provided by the manufacturer to ensure that the steel coils meet the required dimensional standards.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil Workability Durability

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords