PPGI,Pre-Painted Steel Coil/Sheet with Prime Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

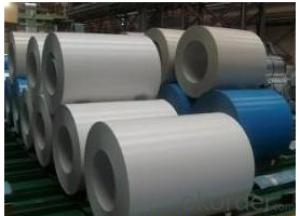

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils inspected for uniformity using statistical analysis?

- Steel coils are inspected for uniformity using statistical analysis by randomly selecting a sample of coils and measuring specific characteristics such as thickness, width, and weight. These measurements are then analyzed using statistical methods, such as mean, standard deviation, and control charts, to determine if the coils meet the desired uniformity criteria. This approach allows for efficient and reliable assessment of the overall quality and consistency of steel coils.

- Q: How are steel coils used in the manufacturing of agricultural implements?

- Steel coils are used in the manufacturing of agricultural implements as they provide strength and durability to the final product. These coils are typically cut, shaped, and welded to create various components such as plows, cultivators, and harrows. The steel coils are an essential material in the construction of these implements, ensuring they can withstand the demanding conditions of agricultural use and effectively perform their intended tasks.

- Q: What are the common methods of forming steel coils?

- The common methods of forming steel coils include hot rolling, cold rolling, and strip casting.

- Q: im buying a sword and i dont know if i should buy a cold steel sword or a normal sword and that i can some how make that cold steel

- This Site Might Help You. RE: how are cold steel swords made? im buying a sword and i dont know if i should buy a cold steel sword or a normal sword and that i can some how make that cold steel

- Q: My musical saw has, despite my best efforts, got little patches of rust on it. How Do I go about removing the rust without spending too much on rust-removal products and without affecting the properties of the steel?

- Steel wool and a bit of WD 40. Steel wool will remove the rust and the WD 40 will protect it in the future.

- Q: What are the different types of steel coil cutting machines?

- In the market, there is a wide range of steel coil cutting machines available, each tailored to meet specific needs and requirements. Some commonly used types include: 1. Slitting Machines: These machines are utilized to cut steel coils into narrower strips. Equipped with multiple circular blades, they are capable of making precise cuts along the length of the coil, enabling the production of narrower coils or strips. 2. Cut-to-Length Machines: Designed to cut steel coils into specific lengths, these machines possess the ability to accurately measure and cut the coil to the desired length, ensuring uniformity and precision. 3. Rotary Shears: Rotary shears are robust cutting machines that can handle thicker and larger steel coils. Utilizing a rotating blade, they are suitable for cutting thicker gauge materials. 4. Multi-Blanking Machines: Intended for cutting steel coils into multiple smaller blanks simultaneously, these machines have the capability to cut the coil into various shapes and sizes. This makes them ideal for producing multiple parts from a single coil. 5. Slit and Cut-to-Length Combination Machines: These machines integrate the functionalities of both slitting and cut-to-length machines, enabling the cutting of narrow strips and lengths in a single process. They offer versatility and efficiency, saving time and increasing productivity. Each type of steel coil cutting machine possesses distinct advantages and is suitable for specific applications. The choice of machine depends on factors such as coil thickness, desired strip width, required length accuracy, and production volume.

- Q: What are the different methods of coil leveling?

- Various industries commonly utilize several methods for coil leveling. These methods encompass: 1. Roller leveling: By passing the coil through a sequence of rollers, pressure is applied gradually, resulting in the gradual flattening of the coil. The rollers can be adjusted to exert varying levels of pressure, allowing for precise control over the leveling process. 2. Stretch leveling: This technique subjects the coil to tension forces, elongating the material and eliminating internal stresses. As the coil is stretched while passing through rollers, a more uniform and flat surface is achieved. 3. Temper leveling: Involving the heating of the coil to a specific temperature followed by rapid cooling, this method helps equalize stresses within the coil and enhance its flatness. Temper leveling is often employed for high-strength steels. 4. Roller leveling with leveling rolls: This approach utilizes additional leveling rolls placed above and below the main leveling rollers. These rolls apply pressure to specific areas of the coil, rectifying any unevenness or distortions. 5. Tension leveling: This method involves applying tension to the coil during processing. The tension aids in straightening and flattening the material, resulting in a more even and flat surface. 6. Precision leveling: Employed for high-precision applications necessitating extremely flat and uniform coils, precision leveling combines roller leveling, stretch leveling, and other corrective measures to attain the desired flatness. Each of these methods possesses unique advantages and limitations. The selection of a particular method depends on factors such as the type of material being leveled, the required flatness tolerance, and the intended application of the coil.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Rust is the process of steel oxidizing when in contact with oxygen, this reaction can be much fast if certain components are present, such as wet air or water. However, if the paint completely isolates the steel from the environment, the encompassed steel will never rust as long as paint shields it. Aluminum corrodes but it does not rust. Rust refers only to iron and steel corrosion. Aluminum is actually very prone to corrosion. However, aluminum corrosion is aluminum oxide, a very hard material that actually protects the aluminum from further corrosion. Aluminum oxide corrosion also looks a lot more like aluminum, so it isn't as easy to notice as rusted iron.

- Q: What are the common problems encountered with steel coils during production?

- Some common problems encountered with steel coils during production include surface defects such as scratches, rust, and scale formation, dimensional deviations, coil breaks or tears, edge defects, and coil slippage. Other issues may include coil handling and storage problems, coil winding or coiling defects, and quality control problems such as inconsistent chemical composition or mechanical properties.

- Q: I just started playing guitar last year. I never changed the chords. When my sister started taking guitar lessons her teacher said that she needed to change the chords. When i bought the guitar it came with steel strings but i bought nylon strings because they are easier on the fingers. The problem is i already tuned up the guitar but it sounds really bad like if it was not tuned. What can i do about this?

- Steel and nylon strings are not interchangeable. Guitars are designed and built for either steel or nylon. Using steel strings on a guitar made for nylon will just destroy the guitar. Nylon strings won't break a steel string guitar, but they probably won't sound that great (different woods sound better with different types of strings)

Send your message to us

PPGI,Pre-Painted Steel Coil/Sheet with Prime Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords