Aluminum Gold Foil Popular Insulated Sandwich Panels Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

insulated sandwich panels price

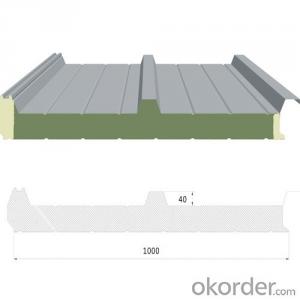

Sandwich panel is mainly composed of color steel sheet and insulation material. The steel sheet mainly include: Powder Coated Galvanized Sheet. The core material mainly include: PU, EPS, rock wool, mineral wool, glass wool, etc

Our panel is fireproof ,waterproof ,heat preservation ,heat insulation ,environment-friendly ,durable in use, color lasting & coated layer keeping

Thickness: | 50mm, 75mm, 100mm, 120mm,150mm |

Material of the panels | composed of colorful steel sheets and Rockwool |

Unit Weight of Core Material | 80kg/cbm,120kg/cbm |

Width of the panels | 1000mm |

Length | As customer' s require |

Panels type | Wall panel and Roof panel |

Surface Texture and Appearance | Small wave, Flat, Embossment, Big rib |

Heat Insulating Material | Rockwool |

Thickness of steel plate | 0.4-0.8mm |

Color of the coating | White grey, Sliver, Sea Blue, Red, etc |

Type of sheet Coating | PVDF, HDP, SMP, PE |

Type of Base steel sheet | Hot-dip galvanized, Al-Zn coated |

Life span | 20 years |

- Q: 3.3 lb aluminum frame / 1.3 lb carbon forkAny good?

- Wow, you're into dropping serious coin on bikes! Cinelli is one of the best frame manufacturers out there - if not the best (there are probably better, but they'd be hard pressed to beat cinelli hands down)Good bike - $1000 for the frame and fork? man, that's steep Think about it - now you have to buy: Wheels tires drive train (a grand again if you want the new Shimano 7800 or the new Campy Chorus 11 speed) brakes bars seat seat post etcYou'll almost pay $3K for this bike - but it will be worth it - just, get ready! Good luck!

- Q: It is an alloy of aluminum foil?

- Or thickness after rolling to form a sheet of aluminum in aluminum foil is 0.2mm or less. Aluminum is added to the aluminum other metals or non-metallic material, so that the metal strength.

- Q: he howls if left on his own too if i got him castrated would that help i cannot take much more please help i cant leave the house

- either or, think its 6 of one and half dozen of the other.insulation kit sounds easier to mess with.vermiculite is ok if your adding it as you build the chimney.

- Q: Hes 10 weeks old and we didnt realise he could jump onto the table, but he did and ate my daughters leftover weetabix with milk

- You will have an historical automobileHistorical cars want extra love than new carsIn case your vehicle wants a head gasket, higher to man up and do it than notIt can be a V-6 so it's more complicated than it's roughThe one actual elaborate phase is resetting the manifoldYou must sneak up on the bolts and do all of all of them whilst grade by gradeFor those who bolt down the manifold on one head first, the opposite part may have a vacuum leak no matter how tight you torque it downButIf you're truly broke (and that i fully realise), you could take out the internal rubber gasket for your radiator cap so you're now not strolling any pressure, cast off the thermostat so you are walking as cool as possible, put black pepper within the radiator water and hope it plugs the position the place water is entering the cylinder(s)Via walking a no-stress cooling method, you are going to overheat at a cut back temperature, so be real cautious to monitor the temp guageIf all you may have is an idiot mild, you may also in finding yourself in a global of harm in an actual rapid hurryFinally you'll ought to change that gasket, with a bit of luck this may get you by using until you set the money together to do it proper.

- Q: I'm making a polymer clay sculpture and the armature contains plaster bandages (the powdery Plaster of Paris kind)I need the clay to harden on the armature as it will lose its shape if I take it offI'm baking it at 130°C (266°F) for 15-20 minutesMy main concern here is if it will burn or fall apart or something, and if so, could aluminium foil be a better alternative? The main issue I have with the foil is it isn't as smooth as the plasterThanks.

- Best No-Bake Cheesecake - .INGREDIENTS 1 1/2 cups graham cracker crumbs 1/3 cup packed brown sugar 1/2 teaspoon ground cinnamon 1/3 cup butter, melted 2 (8 ounce) packages cream cheese 2 teaspoons lemon juice 1 pint heavy whipping cream 1/3 cup white sugar 1 (21 ounce) can cherry pie filling .DIRECTIONS 1.In a small bowl, stir together the graham cracker crumbs, brown sugar and cinnamonAdd melted butter and mix wellPress into the bottom of an 8 or 10 inch springform panChill until firm 2.In a medium bowl, beat together the cream cheese and lemon juice until softAdd whipping cream and beat with an electric mixer until batter becomes thickAdd the sugar and continue to beat until stiffPour into chilled crust, and top with pie fillingChill several hours or overnightJust before serving, remove the sides of the springform pan.

- Q: My mom siad it was what package it had like how much accesories it has inside but I want to know what the XLT has.

- Coming from an ex smoker of 6 years, a bowl is waaaay better than a plastic bottleThat's called the ghetto pipeYour inhaling all sorts of extra, harmful chemicalsPlastic, aluminium foil, yuck! Bowls are way cleanerAs for your question, I don't really know how to answer it lolPipes are made for smoking, you don't have to see the smoke, as long as your doing it right.it will be thereTrust meUse it just like any other pipeLight your lighter, and with your thumb over the carb inhale and within a couple seconds you'll taste the smokeStop inhaling for a second, release your thumb from the carb, and inhale again, which will clear the pipeAs long as it's cherried (embers in the weed) you won't need your lighter againIt's really hard to describe ha haOh and obviously never exhale when your mouth is on the pipe, you'll blow your weed everywhere.

- Q: A piece of aluminum foil is placed over the opening of a 125mL flask and fastened with a rubber bandIt is then placed on a balance and found to have a mass of 75.713 gThe foil is temporarily removed and 10.0 mL of a volatile liquid is added to itThe foil is refastened to the flask and a small hole is made in the aluminum foilThe flask is placed into a 100°C water bathAfter 15 minutes the flask is removed from the bath and allowed to coolAfter drying the flask, it is reweighed and found to have a mass of 76.023 gThe foil is removed and condensed liquid in the flask is disposed of in the waste containerThe flask is then filled completely with water and found to have a total volume of 132 mLIf the atmospheric pressure in the lab is 1.00 atm, what is the molar mass of the compound?

- This is a delicious way to cook fish, especially for those who don't really like fish, like my husbandGet a thick piece or chunk of any type of fish, fresh or frozen, (white fish works best) put in baking dishSpread a generous amount of low fat mayo on topSprinkle lemon juice on thisThen sprinkle with about a half inch of fine bread crumbsBake for about 30 minat 350, until the bread crumbs brown nicelyThe fish is moist and delicious!!

- Q: I am used to Tilapia and Canadian White, catfish etc.I am trying to get used to Salmon for the health benefits, because it is an oily fishAny preparation tips and easy ways to add flavor are really appreciated!

- Try this have a glass of wine while you cook - Yum-Oh Grilled Salmon Steaks with an Oregano Salsa Ingredients aluminum foil 1 tsp butter, unsalted 5 g 1 salmon steak(s) 170 g 1 tbsp white wine 15 mL 1 tsp dried oregano 1 g ground pepper to taste 1 tomato(es), diced 120 g 1/2 green onion(s)/scallion(s), finely chopped 1/2 tbsp extra virgin olive oil 8 mL salt to taste Method Prepare one square of heavy-duty aluminum foil per each steakSpread the butter on the foil, then lay one steak on topAdd the wine, then season with half of the oregano followed by ground pepper to tasteWrap the salmon steaks loosely in foil, sealing the edges securelyCook on a medium-hot grill for about 10 min, until just tenderAlternatively, the fish may be broiled in the ovenCheck with a fork to see if the fish is cooked throughWhile the fish is cooking, finely dice the tomatoes and chop the scallions, then put them in a bowlAdd the olive oil, the remaining oregano, and salt to tasteToss wellServe the salmon hot or cold, covered with the salsa Recommended side dishes Barley Pilaf New Potatoes with Chives

- Q: I'm doing a science project, experimenting on whether or not a matte surface or a shimmer surface will absorb more heat, relating it to matte makeup and shimmer makeupI'm considering on using white printer paper to represent matte, and aluminum foil to represent shimmer, but i figured the aluminum foil was too dramatic to represent shimmerWhat should i use instead of the foil?

- Weed can come in anythingLil baggies,foil,paperIf it was doubly smelly it was weedAlso maybe yes on something else picture would help

- Q: I used to hit some pretty nice shots with my bat, then i went to the batting cages, and then i got dimple ball marks all over, so i went home, and tried to get rid of them, by using car polish ( or something like that) the next day i went to go hit against some live pitching, i kept on grounding everything right into the ground, Do you think the polish made everything slip right off the bat? or was it just me,? and if it was the bat, how do I make it less slipery

- Metamucil is goodand yeah, age doesn't matter reallyBut the absolute best way to get fiber, and make it COUNT, is to get it from real vegetables and whole grainsThere are also a lot of cereals that are full of fiber (FiberOne for example) Good luck!

Send your message to us

Aluminum Gold Foil Popular Insulated Sandwich Panels Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords