Plastic Pipe-PE Gas Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

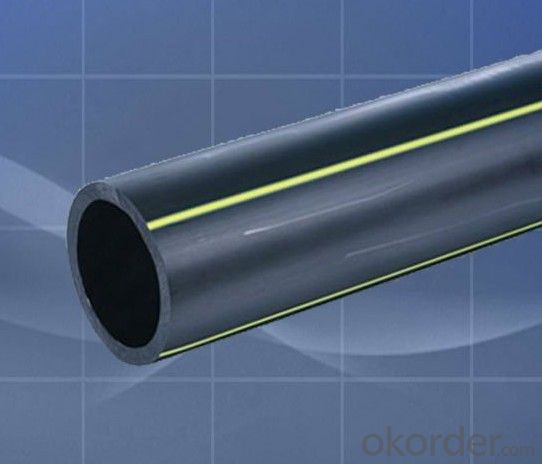

General Information of PE Gas Pipe :

Place of Origin | China (Mainland) |

Material | HDPE |

Specification | dn20~dn630 |

Length | 4m,5.8m,11.8m |

Thickness | Standard |

Standard | ISO4427, ISO4437 |

Raw Material | PE80, PE100 |

Color | Black, Blue |

Temperature | -40℃~60℃ |

| | |

Product Description of PE Gas Pipe:

Material: PE80/ PE100 (mainly PE 100 now).

Sizes: 20mm--630mm

SDR: SDR11, SDR13.6, SDR17, SDR21, SDR26, SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

Advantage of PE Gas Pipe:

1. Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2. Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums, or electron chemical corrosion. except for few strong oxidants

3. High strength, good performance to resist the environmental stress cracking, good creep resistance.

4. Good flexibility: small diameters, PE pipe for water supply can be coiled and supplied for longer length, which saves a large number of fittings, PE pipe can be easily shifted according to requirement of the projects.

5. Light weight, simple safe and reliable welding technique, convenient construction and lower cost of the whole engineering,

6. Smooth interior wall, small water resistance, high flow capacity,

7. Long service life, up to 50 years under normal conditions.

8. Recyclable, benefit to the environment

- Q: How are plastic tubes cleaned?

- Plastic tubes are typically cleaned by using a combination of water, mild detergent, and a brush or pipe cleaner to scrub the inside and outside surfaces. The tubes are rinsed thoroughly to remove any soap residue, and then left to air dry before reuse or storage.

- Q: How do you prevent plastic tubes from becoming brittle in cold weather?

- One effective way to prevent plastic tubes from becoming brittle in cold weather is to use materials with high resistance to low temperatures, such as polyvinyl chloride (PVC) or high-density polyethylene (HDPE). Additionally, insulating the tubes or using protective coverings can help maintain a stable temperature and prevent extreme cold from affecting the plastic's properties. It is also essential to ensure proper installation and maintenance to avoid any potential damage or stress on the tubes that could lead to brittleness.

- Q: Can plastic tubes be used for storing paints or coatings?

- Yes, plastic tubes can be used for storing paints or coatings. Plastic tubes provide a convenient and practical option for storing small quantities of paints or coatings, offering protection from air, light, and moisture, which can affect the quality and shelf life of the product. They are generally lightweight, portable, and easy to use, making them suitable for various applications such as arts and crafts, touch-ups, or small-scale projects.

- Q: Can plastic tubes be used for medical applications?

- Yes, plastic tubes can be used for medical applications.

- Q: Are plastic tubes safe for food and beverage applications?

- Yes, plastic tubes are generally safe for food and beverage applications. However, it is important to note that the safety depends on the type of plastic used and its compliance with food-grade standards. Food-grade plastics, such as polyethylene and polypropylene, are commonly used for manufacturing tubes that come into contact with food and beverages. These plastics are non-toxic, resistant to chemicals, and can withstand the necessary temperatures for food and beverage applications. Additionally, it is vital to ensure that the plastic tubes are properly cleaned and maintained to prevent any contamination.

- Q: Can plastic tubes be used for storing camping or outdoor supplies?

- Yes, plastic tubes can be used for storing camping or outdoor supplies. They are lightweight, durable, and can protect items from moisture and damage. They are particularly useful for storing smaller items like matches, toiletries, or fishing gear, keeping them organized and easily accessible during outdoor activities.

- Q: The difference of PVC plastic pipe and PE pipe?

- HDPE pipe must bear a certain pressure, usually choose a large molecular weight and good mechanical properties of PE resin, such as HDPE resin. LDPE resin has low tensile strength, poor pressure resistance, poor rigidity, poor dimensional stability during forming and difficult connection. It is not suitable to be used as material for feed water pressure pipe. But because of its high hygienic index, LDPE, especially LLDPE resin, has become a common material for producing drinking water pipes. The viscosity of LDPE and LLDPE resin is small, the flowability is good and the processing is easy, so the range of their melt index is wide, and the MI is usually between 0.3-3g/10min.PVC pipe is a kind of plastic pipe with PVC (PVC) resin as raw material and without plasticizer. With the development of chemical industry technology, we can produce non-toxic materials, so it has the general properties of PVC, added some excellent properties, specifically it has corrosion resistance and good flexibility advantages, which is especially suitable for water supply network. Because it does not conduct electricity, it is not easy to react with acid. Alkali. Salt undergoes an electrochemical reaction, so acid. Alkali. It is difficult for salt to corrode it, so there is no need for an anticorrosive coating and lining. And good flexibility, which overcomes the brittleness of plastic pipes in the past, can produce yield under load without rupture

- Q: Hey, my dad asked me to look this up and I can't seem to find it. I am looking for the name of the plastic tubing that has electrical wiring in it. It is used under the concrete in construction. I would also like to know if you know the name of the machine that makes these tubes. Thank you

- Alekat is correct: Schedule 40 PVC conduit is used under or in conduit. This is just an extruded grey plastic tubing, usually 3/4 for a single circuit and larger for multiple or higher amp circuits. After installing the conduit, you have to pull wiring into it (it does not come with wiring inside.)

- Q: Can plastic tubes be used for geothermal heating systems?

- Yes, plastic tubes can be used for geothermal heating systems. High-density polyethylene (HDPE) and cross-linked polyethylene (PEX) are commonly used materials for geothermal piping due to their durability, flexibility, and resistance to corrosion. These plastic tubes effectively transport the geothermal fluid between the ground heat exchanger and the heat pump, making them a popular choice for geothermal heating systems.

- Q: I'm building a science project with my little sister, and we quite frankly need some help. The plan is to make a little rollercoaster out of plastic tubing as the track. It's kind of thick, so it doesn't bend very well. We've been straightening it out for a couple days, but it's still slightly wavy. We need to get it into a solid position. The plan is to support it on some boxes, and maybe tape it down so it holds it's form.But, there is a part in the rollercoaster where it needs to be extremely straight. Any ideas??

- Classic Plastic

Send your message to us

Plastic Pipe-PE Gas Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords