Plastic Film Coated Aluminum Sheet Hot-sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Plastic Film Coated Aluminum Sheet Hot-sale

l Product Information

Aluminum sheet series 1xxx, 5xxx with good corrosion resistance and free from defects and no scratches, often used as raw material of billboard, building exterior decoration,kitchen sink,pieces of electronic, lighting components, giftware, reflectors and sheet metal processing, etc.

| ALLOY | TEMPER | THICKNESS (mm) | WIDTH (mm) | LENGTH (mm) |

| 1050, 1060, 1070, 1100 | O, H12, H14, H16, H18, H22, H24, H26, etc | 0.2-6.0 | 20-2000 | as required |

| 5052, 5754, 5083 | O, H18, H24, H32, H34, H111, H112, etc | 0.2-6.0 | 20-2000 | as required |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

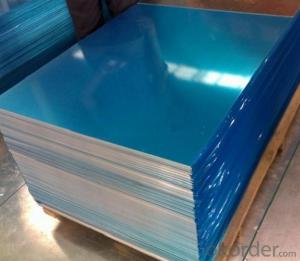

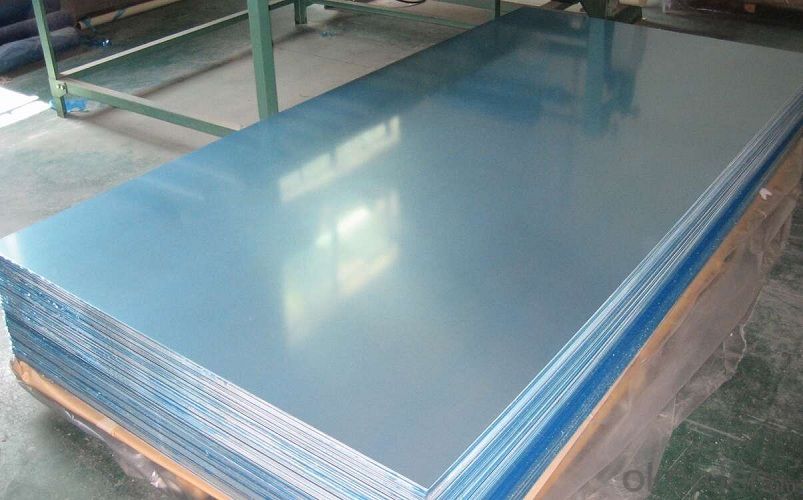

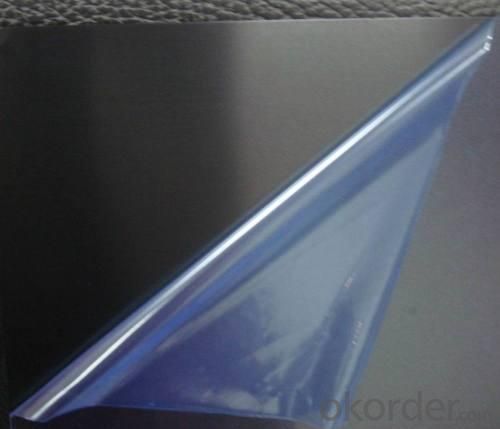

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: This question asks for guidelines on how to properly store aluminum coils to ensure their safety and longevity.

- <p>To store aluminum coils, follow these steps: Ensure the storage area is clean, dry, and free from dust and moisture. Keep the coils on wooden pallets or racks to avoid direct contact with the ground. Stack the coils with the same size and type to prevent damage. Use protective wrapping or covers to prevent scratches and dirt accumulation. Maintain proper ventilation to prevent condensation. Store coils away from corrosive materials and chemicals. Regularly inspect the coils for any signs of damage or corrosion. By following these guidelines, you can maintain the quality and integrity of aluminum coils during storage.</p>

- Q: I was wondering if you could mold clay into a sphere then fill it with aluminum. Then put it over a fire and wait until the aluminum melts then put it in a freezer and it would come out as a sturdy, aluminum sphere. Thanks!

- Do not try this at home! Seriously, this is exactly the kind of process that is used for casting metals. However, you need to have very strong molds with no cracks in them. Also, aluminum presents special problems. Solid aluminum does not corrode the way iron does, because it very quickly forms a protective tough layer of aluminum oxide. But molten aluminum can catch fire, with devastating consequences.

- Q: Is it possible to utilize aluminum coils in the construction of solar panels or wind turbines?

- <p>Aluminum coils can be used in the construction of both solar panels and wind turbines, but not as the primary material for energy conversion. In solar panels, aluminum is often used for framing and mounting structures due to its lightweight and corrosion-resistant properties. For wind turbines, aluminum is utilized in the manufacturing of certain components such as nacelle shells and towers, but the main rotor blades are typically made from composite materials for their strength and aerodynamic properties. Thus, while aluminum plays a supportive role in these renewable energy technologies, it is not the core material for capturing solar or wind energy.</p>

- Q: How do aluminum coils compare to fiberglass coils in terms of weight?

- Aluminum coils are generally lighter in weight compared to fiberglass coils. Aluminum is known for its lightweight properties, making it an ideal choice for various applications, including coil manufacturing. Fiberglass, on the other hand, tends to be denser and heavier than aluminum. This weight difference can have several advantages when it comes to installation and transportation. Lighter aluminum coils are easier to handle, require less effort to install, and can be more cost-effective in terms of shipping and logistics. Additionally, the reduced weight of aluminum coils can contribute to overall energy efficiency in HVAC systems, as it requires less power to move and circulate air through the coils. However, it's worth noting that the weight comparison between aluminum and fiberglass coils may vary depending on the specific design and thickness of the materials used.

- Q: What is the minimum width of aluminum coils?

- The minimum width of aluminum coils can vary depending on the specific requirements and manufacturing capabilities. However, in general, the minimum width of aluminum coils typically ranges from around 0.25 inches to 0.5 inches. It is important to note that specialized manufacturing processes may allow for even narrower widths, but these are less common and may come with additional costs or limitations. Additionally, the specific application and industry requirements will also play a role in determining the minimum width needed for aluminum coils.

- Q: Are aluminum coils fire-resistant?

- Aluminum coils possess fire-resistant qualities due to their high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and their inability to burn, rendering them non-combustible. This specific characteristic allows for the utilization of aluminum coils in various applications, particularly in sectors where fire resistance is of utmost importance, such as building construction, electrical wiring, and HVAC systems. Moreover, the remarkable heat conductivity of aluminum facilitates rapid heat dissipation, thereby minimizing the risk of fire incidents. Nevertheless, it is crucial to acknowledge that although aluminum coils themselves exhibit fire-resistant properties, they may be incorporated into systems alongside other components that might not share the same level of fire resistance. Consequently, it is essential to consider the entirety of the system and adhere to proper fire safety regulations and guidelines to ensure comprehensive fire safety precautions.

- Q: I was wandering, if your spear's shaft is made of aluminum, does that have any strength to it, i mean, say you had to block with the shaft, would a weapon break through like your basic sword or basic axe, i don't mean big heavy swords and axes, but like average ones, could it break through an aluminum shaft of a spear?

- nice question dear.. but strength is depend upon the hardness of material.. if that spear's shaft is hollow it can withstand up to certain level only for slow strikes.. but shaft is a rod hopefully i can say block using that even with a basic katana and Axe.. and one more thing your should strike as sparring and for fighting..

- Q: Some manufactures (Kia, Hundai) use Iron blockswhileOther manufactures (Nissan, Chevy, ect.) use Aluminum blocks*****Is the point of using Iron blocks to increase long-term durability or temperature endurance??ORIs the use of Iron blocks simply an older, simpler technology (as compared to using Aluminum), the manufacture of which costs less money??And you would think that Aluminum weight savings would transer to better MPG, but the Kia gets very comparable mileage anyway.Thank you

- Aluminum's main advantages are weight and increased mpg for CAFE regulations. If you are going to keep your car to 150,000 miles eitheir block material will do. But if you are going to keep it 300,000 to the bitter, bitter end, you are better off with iron.

- Q: Can aluminum coils be used in packaging industries?

- Indeed, the packaging industry can utilize aluminum coils. Aluminum emerges as a favored option for packaging materials owing to its abundant advantageous properties. It possesses a lightweight nature, durability, resistance to corrosion, and exceptional thermal conductivity. Such attributes render aluminum coils appropriate for a variety of packaging applications encompassing food and beverage packaging, pharmaceutical packaging, and cosmetic packaging. Moreover, aluminum stands out as highly recyclable, thereby constituting an environmentally conscious choice for the packaging industry. All in all, aluminum coils deliver remarkable performance and versatility, rendering them a fitting choice for packaging industries.

- Q: Are aluminum coils recyclable?

- Indeed, recyclability applies to aluminum coils. As one of the most easily recyclable substances, aluminum can be recycled ceaselessly without compromising its integrity. The process of recycling aluminum coils entails melting them down to create fresh coils or alternative aluminum goods. This practice not only diminishes landfill waste but also conserves energy and resources necessary for manufacturing new aluminum from primary materials. Opting for the recycling of aluminum coils is an environmentally conscious decision that aids in the preservation of natural resources and the mitigation of greenhouse gas emissions.

Send your message to us

Plastic Film Coated Aluminum Sheet Hot-sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords