Rv Solar Percussive Drilling Pile Mounting System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10watts watt

- Supply Capability:

- 1-1000000watts/month watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of the Percussive Drilling Pile Mounting System

Packaging Detail: wood case, wood pallet ,carton

Delivery Detail: 10- 15 working days

Specifications of the Percussive Drilling Pile Mounting System

Solar ground mounting system:

1.Easy installation

2.High durability

3.Standup to extreme weather

4.long Warrenty

Product description of the Percussive Drilling Pile Mounting System

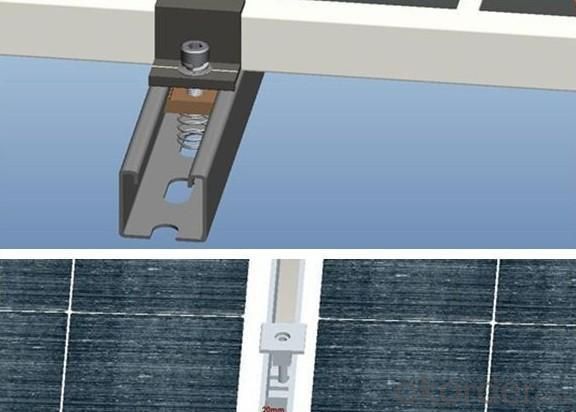

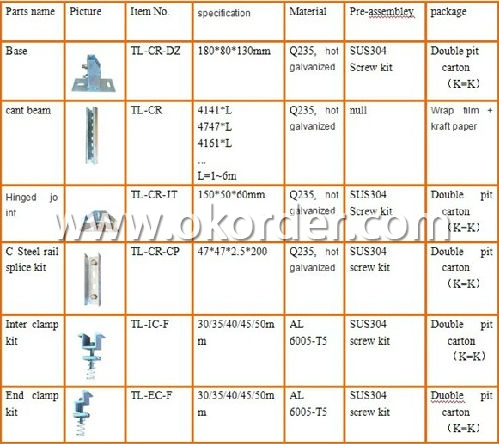

Ground mounting structure which is applicable to construct photovoltaic power mounting with high anticorrosive performance. The mounting system Using the edge stress C steel as main body and integrates with spare parts, such as C steel splice kit and spring module etc…For the convenience of customers, we are ready for all kinds of specifications C steel, such as 41*41*2.0mm, 47*47*2.5mm, 41*61*2.5mm etc…Of course, we can also be customized according to All mounting accessories is pre-installed SUS 304 screws before shipment to minimize the time and cost of installation.

The details of the Percussive Drilling Pile Mounting System

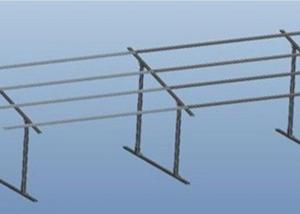

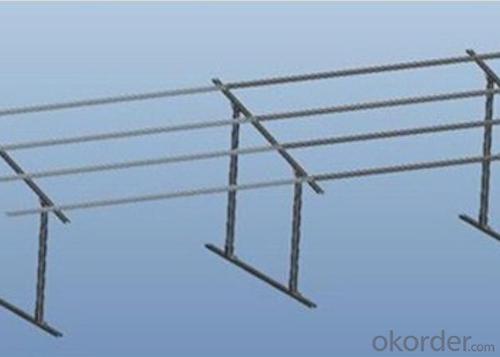

The show of the Percussive Drilling Pile Mounting System

The package of the Percussive Drilling Pile Mounting System

- Q: What is the difference between a roof-mounted and ground-mounted solar system?

- A roof-mounted solar system refers to solar panels that are installed on the roof of a building, while a ground-mounted solar system refers to panels that are installed on the ground. The main difference lies in the placement and orientation of the panels. Roof-mounted systems are commonly used when space is limited or to utilize the available roof area for solar energy production. On the other hand, ground-mounted systems are installed on the ground and can be placed at an optimal angle and direction to maximize sunlight exposure, making them more flexible in terms of positioning and potential energy output.

- Q: Can a solar mounting system be used with solar-powered RVs?

- Yes, a solar mounting system can be used with solar-powered RVs. A solar mounting system provides a secure and efficient way to install solar panels on the roof of an RV, allowing for the harnessing of solar energy to power various appliances and systems within the vehicle.

- Q: Can a solar mounting system be used with solar air heating systems?

- Yes, a solar mounting system can be used with solar air heating systems. A solar mounting system provides the necessary structure and support to install solar panels, which can be used for both photovoltaic (electricity generation) and solar air heating systems. By using a solar mounting system, solar air heating collectors can be securely mounted on rooftops or ground-mounted structures to harness solar energy for heating purposes.

- Q: Can a solar mounting system be used with solar-powered planes?

- No, a solar mounting system cannot be used with solar-powered planes. Solar mounting systems are designed to support and position solar panels on the ground or on rooftops, whereas solar-powered planes have their own custom-built structures to house and integrate solar panels for generating power.

- Q: How does a solar mounting system protect against wind damage?

- A solar mounting system protects against wind damage by securely anchoring the solar panels to the roof or ground. It uses strong and durable materials, such as aluminum or steel, along with advanced engineering techniques to withstand strong winds. The system is designed to distribute the wind load evenly across the structure, reducing the risk of damage or displacement. Additionally, the tilt angle and positioning of the panels are optimized to minimize wind resistance.

- Q: What is a finished stent?

- Finished stents are directly from the factory to produce stereotypes of the channel and a variety of connectors, and then by the construction staff on-site assembly of the stent system.

- Q: Can a solar mounting system be used with solar balcony railings?

- Yes, a solar mounting system can be used with solar balcony railings. The mounting system allows solar panels to be securely attached to the railings, enabling them to harness the sun's energy and generate electricity. This provides an efficient way to utilize solar power even in limited space such as balconies.

- Q: Can a solar mounting system be used in areas with solar incentives for hotels?

- Yes, a solar mounting system can definitely be used in areas with solar incentives for hotels. These incentives are typically designed to promote the adoption of renewable energy sources, such as solar power, and encourage businesses like hotels to install solar panels. By utilizing a solar mounting system, hotels can easily install and maximize the efficiency of their solar panels, enabling them to take full advantage of the available incentives and reduce their electricity costs while promoting sustainability.

- Q: Can a solar mounting system be installed on a concrete roof?

- Yes, a solar mounting system can be installed on a concrete roof. Concrete roofs provide a stable and durable surface for mounting solar panels. However, it is important to ensure that the concrete roof is structurally sound and can support the weight of the solar panels and the mounting system. Additionally, proper waterproofing and sealing measures should be taken to prevent any water leakage or damage to the roof.

- Q: Can a solar mounting system be used with solar-powered educational programs?

- Yes, a solar mounting system can be used with solar-powered educational programs. The mounting system helps secure and position the solar panels, enabling them to efficiently capture sunlight and generate electricity. This electricity can then be used to power educational programs, providing a sustainable and eco-friendly energy source for various educational activities.

Send your message to us

Rv Solar Percussive Drilling Pile Mounting System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10watts watt

- Supply Capability:

- 1-1000000watts/month watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords