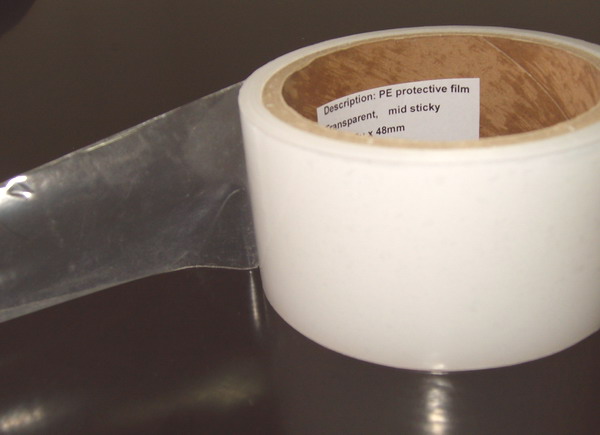

PE protective flim HN-60B

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Total Thickness (adhesives + carrier):60+10%micron

Colour: Black & White

Density 0.95g /cm3

Tensile Strength (Long): >18N/25mm

Tensile Strength (Trasv): >13N/25mm

Adhesion (to stainless steel):150g/25mm

Elongation at break-MD: >200%

Elogation at break-CD: > 350%

Static Shear 23 DC: >48 hours

Storage: 35 DC

Humidity: 80%

Shelf: 6 months

- Q: How to remove the protective film on stainless steel door after using for a long time?

- Use electric hair dryer.

- Q: How many kinds of materials can be used to produce the protective film for flooring finish?

- Commonly, the materials used in the protective film for flooring finish can be classified into: PE (polyethylene), PET (polyester), CPP (polypropylene), PVC (polyvinyl chloride), OPP, etc. 1.PE films have many colors. The most common colors are transparent, blue, black and white, as well as milky. Apart from these, there are black, grey, green, yellow, orange, gold, red and so on. PET films are usually transparent, grey and golden. 2. Usually, CCP film is matte. It's a kind of film with foggy effect. 3. PVC film is often transparent. Apart from that, there's a kind of blue static film. 4. OPP film is generally transparent and adhesive. Among all, the types of PE film are the most including PE adhesive film, PE static film, PE textured film, PE stretch film and PE packaging film. The adhesion of such film can be classified into degrees from 5g to 270g; and the thickness, from 1.5C to 15C. The adhesion of the most widely used film is 5C. PET films can be divided into PET film with silica gel, matte PET film, three-layered PET film, Single-layered PET film, two-layered PET film and PET release film. PET protective films are usually used on the protection of a variety of screens. PET release films are often used in the punching of PET protective films in die cutting factories. The adhesion of most commonly used punching is 5C or 7.5C. And the adhesion of the most commonly used release film is 2.5C, 3.8C, 5C or 7.5C. PET color is generally transparent, gray, gold.

- Q: Can laptop TouchPad be covered with protective film?

- I used protective film to coat the wrist rest··and the touchpad too. But I found the touchpad got slow to respond·

- Q: What's the difference between radiation and static? How can I know the protective film is anti-static or not? What harm can static do?

- Radiation is a kind of wave with penetrability. Any heat source generates radiation to some extent, strong or weak. Radiation is harmful to human body. Display, keyboard and mouse generate radiation, though very little. There's no problem if you don't use them for too long. But if it's nuclear radiation, it will damage human body very badly, even cause death. Static is a kind of phenomenon that occur because of electrostatic force generated by the interaction of point charges. Static can be generaed by friction. It may happen when screen is used for a long time. Static itselt does no harm to human body. But if your hands is static, when you touch precise instruments, the instruments may be damaged. That's because static can produce little sparks that may cause fire if there's something inflammable. The static on screen can be eliminated by wiping with damp towel. Protecive film separates the screen and electrons. Thus it's anti-static.

- Q: Why must the protective film on plastic steel window be torn off?

- It will be difficult to remove after the window is installed for too long.

- Q: What to do if there are some white dots on the protective film coated on high-light product?

- Please use protecive film of better quality. The foggy white dots may be generated because the glue reacts with the air.

- Q: What is a self-adhesive protective film?

- No residual glue, mobile phone protection film belongs to self-adhesive protective film

- Q: Why does PE film curl when rolling it after coating?

- It may happen if the temperature of equipment is too or glue of high adhesion is applied to fairly thin flim. (The solution is to increase the speed or decrease the temperature.) The adhesion of glue is too high because it's too thick, or the base material is not good, or the stress is too strong when drying the film.(Solution: using the inlet air to press the film from the right side to make it flat and ensure the glue won't fall off.) And if the film you use is composite membrane, when the composite membrane is not composited compeletly, the same problem may occur too. I don't know your coating process, thus all above are the possible reasons that I suppose.

- Q: What to do if the sandblasted protective film on marble stele is not adhesive any more?

- The reasons may be: 1. If there is oil or water on the surface of the processed stele, the film can't be sticked firmly. 2. Maybe the adhesion of the protective film is not enough. I suggest you try a new film that is more adhesive. We have recieved many similar complaints from our customers. Generally, we will provide them with a variety of protective films for testing.

- Q: Is it necessary to tear off the protective film on surveillance camera?

- If the lens, infrared light or photoresistance of the surveillance camera is covered with protective film, I suggest you to tear the film off after the installation. Otherwise it will affect the image definition, the light or the sensitivity of opening infrared light. And it may affect the heat dissipation of relative parts, causing high temperature and unstable operation of the equipments.

Send your message to us

PE protective flim HN-60B

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords