Extra Thick Aluminum Foil PE Film for Diverse Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyethylene(PE) Composite with Aluminium Foil and Paper

1) Structure of PE Composite with Aluminium Foil and Paper Description:

Since PEG is a flexible, water-soluble polymer, it can be used to create very high osmotic pressures (on the order of tens of atmospheres). It also is unlikely to have specific interactions with biological chemicals. These properties make PEG one of the most useful molecules for applying osmotic pressure in biochemistry and biomembranes experiments, in particular when using the osmotic stress technique.

PE has the characteristics of high mechanical strength, good rigidity, strong toughness, excellent electrical insulation properties, transparent, high gloss, non-toxic, odorless, tasteless, resistance to abrasion, folding, pinhole resistant and anti tearing etc.

2)Main features of the PE Composite with Aluminium Foil and Paper:

. Flexible and durable

. Light and easy to transport

. Fast delivery

. Item shipped from Dubai warehouse

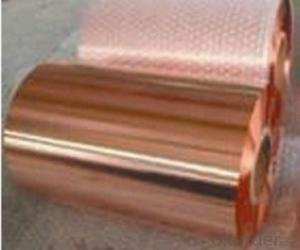

3)PE Composite with Aluminium Foil and Paper Images:

4)PE Composite with Aluminium Foil and Paper Specification:

Model | HSCG-450X2 | |

T-shirt bag | Width | 200-400mm |

Length | 300-600mm | |

Thickness of film | 0.01-0.05mm | |

Speed | 250-300pcs/min | |

Machine | Weight | 2600kg |

Power | 12.5kw | |

Air compression | 10hp | |

Dimensions | 7000x1600x1800mm | |

5)FAQ of PE Composite with Aluminium Foil and Paper:

1. 30% T/T advance , then balance before shipment or against BL copy. Or 30% L/C payment, balanced duaring 30-60 days.

2. The other specific issues can be negociated.

3. Any problem, feel free to contact us. We will reply as soon as possible.

- Q: what can i cook on the grill that is healthy? I have chicken and beef, i also need a side that is healthy, no salad i had it for lunch and dinner for the last 3 daysbut hey i lost a few pounds!

- No clue here.brother.but did ya know.the fine dust looking stuff in with each stick of gum is granite dust?.really.who would have thunk?

- Q: I've got some samples made of aluminium alloy (HE30 BS1476)They've been solution treated at 520°C for 90 minutesWhat difference in hardness (from just after the treating) can I expect to get in one week, leaving the sample at room temperature and WHY?

- Your best bet is to take a sample and send it to a labSend an original piece before solution treating then another after treating and another after one weekThe values of hardness have a range depending on the treatment process and the age of the materialSomeone might be able to ballpark a value but you won't really know what it is until you've had it tested.

- Q: what is the effective nuclear charge on the 1s electron of a neutral Al atom?

- If you haven't taken it out of the oven yet, leave it in for 5 minutes or so, checking to see if it's done by sticking a clean toothpick in the centerIf it comes out clean, it's doneIf still wet batter on it, leave it a few more minutes can check againIf you have taken it out and it;s cool-you can scoop out the raw part and fill it with pudding, or other filling, or cake crumbs mixed with enough frosting to bind it and use it as a Mystery filling!

- Q: This is on a Science test so please be specific, but i dont want a story long paragraphahahaa, unless it's important.To make a gladiator, Which one would you rather use: Steel OR Steel and Aluminum.Thank youu.!

- Or you can just toss it in a crock pot for about 6 to 8 hours with some peeled potatoes.

- Q: it's for a recipe here:Set oven at 300 degreesBaste ribs with the Barbecue sauceWrap ribs tightly in plastic wrapPlace wrapped ribs on large sheet of aluminum foil, seam side upWrap the plastic-wrapped ribs in the aluminum foil, making an envelopePlace envelope of ribs on a cookie sheet or in shallow pan, seam side upPlace in heated oven and bake for 3 hoursUnwrap and serveBe very careful as there will be steam build-up inside the packageServe with coleslaw, baked beans and hush puppies or corn bread.I don't; i thought it might melt.

- Traditionally the answer is to strap the wallsThis means putting battens (studs) on the wall and fixing insulation board to them leaving a gap which can be left empty or filled with insulation materialTo save money, try going round all the local building sites and demolition sites and ask for scrap battens and board - they will be in small bits, but you can manageTry looking in skips, especially industrial estatesGo to insulation firms and ask for left over material - it's amazing how much these firms throw away because the bits are too small for them to botherDo the coldest wall firstGo skip hunting for all your needs - I do!!

- Q: I know certain plastics can produce harmful gas when burned, but what about if it is covered in aluminum foil, then oven bake clay? The doll has no hair, and will be completely covered in clay with no parts of the plastic doll directly exposed to the heatI am mainly using the barbie as a inner mold because I have cubital tunnel syndrome and cannot sculpt with my hands for a long period of time, and I need this done within the next few weeksI also have a ceramic kiln, but never tried Primo clay in it before as it is such a low temp clayI thought maybe if I just lowered the temp to maybe 200 and baked for a longer period of time, it would be okSomeone suggested coating the barbie in a plastic high temp spray for like outdoor grills, but I don't know anything about that kind of thingAnyone have any experience doing this? Thanks!

- Here are a couple of very simple recipes for you to make after a long days' workI need to preface this with your grocery shoppingBuy some chicken parts (whatever you like - thighs, breasts, etc.) and pork chops when you go grocery shoppingWrap them in saran and place in zip lock bags in individual portions you will want for dinnerFreeze themThen, when you get home from work, take out two (since you said both), take a can of cream of whatever soup (mushroom, chicken, celery, etc.) and place the soup and about 3/4 can of water in a potStir the soup until the water is mixed inThen add your frozen meat and turn on the burnerWhen it comes to a boil, turn it down to a simmer, cover it, and cook for 30 minutesIt will be done perfectly in that timeframeIf you use thawed meat, it may dry out but frozen works perfectlyServe with some instant rice (if you have it - that takes apx 5 minutes to make after your water boils)Make earlier in the week a mixture of chopped lettuce, radishes, celery, and carrots and put in a zip lock bag - don't press the air out - you want the air in the bag to keep it freshThen you can dole out however much salad you want for each mealIt will last about 3-4 days before starting to turn brownDon't put cucumber or tomatoes in it in the bagAdd them just before servingHope that helpsYou can also take that salad base, top it with some cooked shredded chicken, diced apple, cranraisins, toasted pecans, sunflower seed, and pine nuts, then add a little Feta cheese and serve it with Raspberry Vinaigrette (Knotts Berry Farm makes a good one).

- Q: i made some (FIMO) polymer clay miniatures that are about the size of a marbleis it okay to bake them in a Ziplock bag? (so the oven wont get messy, and the ziplock bag will collect the residue)and how long should i bake them for? they're really small, so i think 260F/130C is too hot for them??Thanks:)

- Don't use the plastic bag, line an old cookie sheet with aluminum foil and bake them on thatI usually bake at a few degrees lower and a few minutes shorter than the package suggests, especially for tiny piecesIf you cook it too long or too hot, there will be crackingIf you don't cook it long enough, it will stay pliable when cooled To be sure, bake a piece of scrap clay roughly the same size as the pieces you are going to bakeIf it looks good after it's cooled, you have the green light to bake your mini works of artIf not, test again at another time or tempHope this helps;)

- Q: I am having a holiday get together for about 8-10 people and I want to smoke something on my grillI have 418 sqinches of grill spaceWhat do you recommend?

- For a very strict jew everything that touches the food must be kosher not just the food itself that is why that is found on food related items as well as food items themselves.

- Q: I'm purchasing an AR-15 that just has an aluminum free-float tube handguard, and I want to replace it with the YHM free-float quad-railDo I need a special YHM barrel nut, or can I use the free float nut it already has? I'm trying to avoid removing the gas system and flash hider.

- Yankee Hill Free Float Handguard

- Q: I have had a few rusty nails, and I tried to scrape them off to make IRon oxide, for a projectBut I tried to scrape with a knife and crumpeled aluminum foil, nothingJust little very tiny bits, which disapear into the surface of the bagWhat am I doing wrong? Or, if you don't know what is another way to make Iron Oxide (rust)? Please Help?! PLEASE PLEASE PLEASE PLEASE HELP ME PLEASE

- By collecting them as trash and use them for creating paper again and other itemsYou can find recycling procedures in other sitesBut paper also can be recycled as food for germs and other fungus and bacteria in order to produce and enrich soil for plantsThe only problem is that you can't use this method for edible plantations since paper contains chemicals that are not always healthyBut some sort of papers can be used for that reasonAlso paper can be used as fuel and this can be considered as low cost recycling.

Send your message to us

Extra Thick Aluminum Foil PE Film for Diverse Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords