Packing film PVC Stretch Film made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

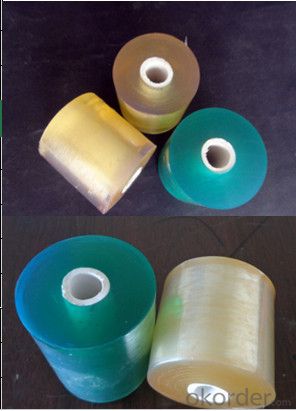

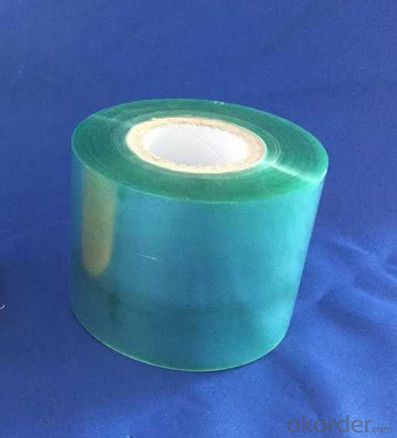

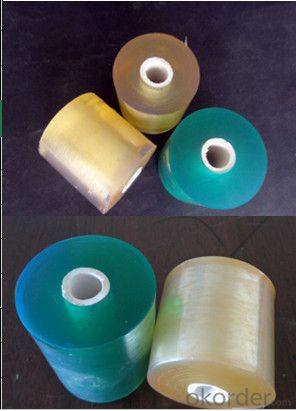

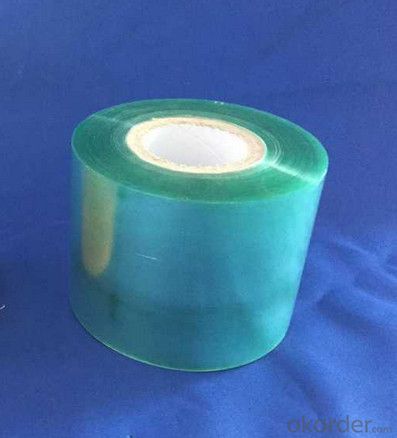

PVC Stretch Film

Material: PVC

Thickness: 18-100 micron

Width: 10-150 mm

Color: transparent, green, yellow, and so on ( The film looks colorful, but when you pull it out you will find no color, totally transparent)

Application: widely used in electrical wires, cables,various steel, precision roller, hardware accessories, furniture, building decoration materials, tourism sneakers, etc.

Feature:

1. Excellent soft

2. Good tensile resistance

3. Without secondary pollution during usage

Item No, | Thickness micron | Total roll weight | Adhesion (N/cm) | Tensile strength (Kg/cm) | Elongation |

APF-20 | 20 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-40 | 40 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-60 | 60 | 250gram/ 70mm | 1.7 | ≥350

| ≥80%

|

APF-80 | 80 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

APF-100 | 100 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

- Q: Is plastic film made of turning? Is the machine expensive?

- The unit adopts special structure of screw extruder, screw die advanced, adjust the cooling wind ring flexible, reasonable aperture type foam structure, so that the mixed plastic three polyethylene and different proportions of uniformity, good product quality, convenient operation, stable and reliable production.

- Q: What is the difference between a thin film keyboard and a mechanical keyboard?

- The general mechanical keyboard is playing a game, there is no key conflict. The film feels free of mechanical keyboards, and the film keyboard is a plastic leather cushion. Mechanical keyboard which is a separate switch which is spring. Mechanical keyboard touch each axis of different axes are not the same playing games. Black tea black shaft shaft shaft shaft to trigger a little faster than tea tea axis has the sense of paragraph no office green black shaft shaft.

- Q: The material, characteristics and uses of various plastic films

- This product of EVA film blowing out the most used plastic film, greenhouse film, bags and other uses in bacteria.These products are the most common and most commonly used in our life. Both the production and sales volume are very large, and they are in use both at home and abroad.Hope to help you; if you don't understand, you can continue to ask.

- Q: What's the difference between PE plastic film and PVC plastic film?

- PE is polyethylene, that is, plastic wrap, that is, PE sprinkle. PVC is PVC, that's about plastic pipes. Which ones need to be used?.

- Q: How often will the plastic film in the greenhouse be replaced?

- There is no fixed deadline, mainly to see the integrity and transparency of the greenhouse films, if maintain proper, by cleaning and repairing can meet the use requirements, can be reused for years, saving the cost; if improper maintenance, natural or man-made damage is serious, a year could be replaced several times.

- Q: Will iron make any pollution when it is melted again?

- Like the plastic film made of polyethylene, polypropylene, EVA and other plastic is generally non-toxic, widely used in food packaging industry. And PVC plastic plastic film due to the addition of stabilizers containing lead and cadmium, it is harmful to humans, but if the use of PVC non-toxic formula (using non-toxic stabilizer and plasticizer, etc.) made of plastic film can be used for food packaging.

- Q: What's the packing material for yogurt? Plastic bags, then what plastic film, and can not use carton packaging?

- Yogurt packaging mostly for blister and blow molding, material PE, PP based, plastic film mostly BOPP film, carton packaging higher cost, carton packaging basically three layer printing layer, carton and inside a layer of film

- Q: PVC plastic film, ultrasonic welding machine welding, welding can.

- When the lines are increased, the effect of welding is completely different from that of the high frequency machines. The specific performance is pale, the fastness is not enough, the lines are not good, and the holes will appear.

- Q: What's the plastic film on the disposable paper cup?

- The wax coated cup is coated with a layer of wax used to separate the water.The polyethylene film cup is the film covered with polyethylene in the cup wall.The wall of the double wall cup has two layers of paper. There is air between the paper and the paper, and the insulation is very good.

- Q: Plastic film surface corona treatment, the bigger the better?

- With our experience and Shun packaging, plastic film on the surface of the corona treatment is not better, if the surface treatment of plastic film spark is too large, will make the surface film breakdown, aging, luster faded, heat sealing performance of adhesion, strength reduction or inner film variation, is not easy to seal.

Send your message to us

Packing film PVC Stretch Film made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches