Operate Flexibly Complete Pet Bottling Line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

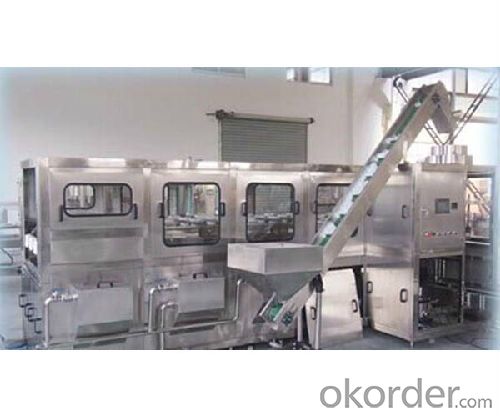

Operate Flexibly Complete Pet Bottling Line

1.Structure of Description

Water filling line/liquid filling line includes: Washing-filling-capping 3 in 1 machine, lamp inspection, label shrinking machine, inkjet printer, hot shrink film packer and conveyors. It is a full automatic production line.

The water filling line is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machinery of the same specifications.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

3. Images

4. Specifications

Type:Filling Machine

Application:Beverage

Packaging Type:Bottles

Packaging Material:Plastic

Rated Output:300 bottle/hour

Compressed Air Consumption:0.4Nm3/min

Water Consumption:7.4m3/h

Power:11.3KW

Model Number:QGF-300

Dimension(L*W*H):4080×1880×2200mm

Weight:2000KG

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (1) calculate the average of two samples;(2) the variance of two samples was calculated;(3) which packaging machine is more stable in packing quality?(1) according to the average, the number divided by the sum of each group;

- Q: What machine does the packing carton machine have?

- Packaging equipment including: automatic strapping machine, automatic sealing machine, winding (wrapping) machine, sealing and cutting / shrink machine, vacuum packing machine, automatic strapping machine band and hand tools. Transport equipment mainly include: conveyor belt, roller conveyor, conveyor chain plate, plug-in production line, chain conveyor, conveyor belt etc..

- Q: The role of packaging equipment in packaging equipment

- Some products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.(8) it can promote the development of related industriesPackaging machinery is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, any discipline problems will affect the overall performance of packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.

- Q: What's the best place to use the pillow type packing machine?

- This device is now relatively mature technology, but each manufacturer's design is still a little different

- Q: What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packing machine? Should the packing of the tableware be contracted? Tak Cheung packing machinery, automatic heat shrinkable tableware packing machine can be considered

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: What are the structures of the packaging machinery?

- Is a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on.

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Molding: mainly used for thermosetting resins. There is a special molding machine. Molding pressure is much greater than the above. The mold structure is also more complex.

Send your message to us

Operate Flexibly Complete Pet Bottling Line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords