FULLY-AUTO L BAR SEALER and SHRINK TUNNEL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

SF-400LA is a fully automatic unmanned operation “L” type sealing machine which is widely used in mass production packaging line with high efficiency. Automatic film feeding punching device, manually adjustable film-guide system and feeding conveyor platform make the machine suitable for different width and height items. SF-400LAC has closely connecting function which specially designed for small items

Sealing knife uses the aluminum knife with DuPont Teflon which is anti-stick coating & anti-high temperature. So the sealing will not have cracking, coking and smoking with zero pollution;

Equipped with imported photoelectric of horizontal and vertical detection for choice to easily finish the sealing of thin and small items;

Automatically-feeding: the length can be auto adjusted by the sensor and time relay. Matched the reduction motor makes the waste film automatically rolling;

When the packaging size changes, the adjustment is very simple by rotating the hand wheel without changing molds and bag makers;

Different size products can also be packaged combinations to achieve the promotional effect;

Using original Autonics digital temperature controller which built-in PID function. Sealing blade temperature is extremely sensitive and accurate and we can be arbitrarily set. Do not worry about hurting the product for imprecise temperature. The sealing blade itself is also equipped with automatic protection function which effectively prevent from accidental cutting;

The machine is equipped with organic glass shield with automatic alarm function which greatly improves safety;

The entire machine realizes unmanned operation with the production line connecting;

l Film up-down synchronization mechanism specially designed to correct the deviation film;

l I can be added easily tear functions according to customer requirements;

l Applies to software, food, cosmetics, printing, pharmaceutical, flooring, ceramic, beverages, hardware and other industries’ large quantities of shrink wrap

Parameters

Model | SF-400LA | SF-400LAC | SF-4525 |

Power | 2.2kw | 2.3kw | 9kw |

Power Supply | AC 220V 1/3PH 50/60Hz | AC 220V 1/3PH 50/60Hz | AC 380/220V 50/60Hz 1/3PH |

Max. Packing Size L×W×H | L+H≤530mm W+H≤430mm H≤135mm | L+H≤530mm W+H≤430mm H≤135mm | 1000×300×200mm |

Max. Sealing Size L×W×H | L550×W450mm | L550×W450mm | / |

Packing Speed | 15m/min. | 15m/min. | 0~20m/min. |

External Air Source | 6-8kg/cm2 | 6-8kg/cm2 | / |

Shrink Film | POF | POF | POF |

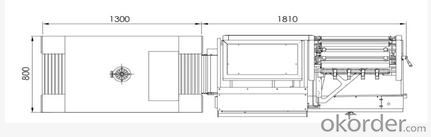

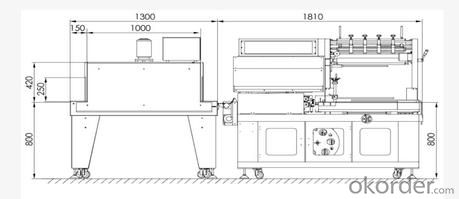

Machine Size L×W×H | 1810×880×1600mm | 1810×880×1600mm | 1300×800×1520mm |

Packaging Size L×W×H | 1860×930×1750mm | 1860×930×1750mm | 1350×850×1670mm |

G./N. Weight | 330/280kgs | 380/300kgs | 320/280kgs |

- Q: Where is secondhand corrugated paper packaging machinery available?

- Carton factory and general production enterprise is different,General business is to face direct consumers, the need for their own sales network, sales staff, sales means......And carton factory as long as accurate manufacturers, show their means, get business.Maybe you walked into a food factory, an electrical factory, a furniture factory, a toy factory...... Can be your client.With business, but also to choose their own plant.Cartons are flammable and afraid of water. This is the disadvantage of cartons. If handled properly, there will be no problem.Site is best to avoid low-lying and rainy lots of water, the cardboard should not be piled directly on the ground, the bracket is a good choice.No smoking in the factory area, no open fire, and good fire fighting equipment, so as to ensure the safety of production.The size of the initial plant is best to be 500 square meters, or larger, smaller.

- Q: What is the general packing cost of beer beverage packaging?

- A privately owned enterprise production and processing, wholesale distribution, production of various types of complete packing machine, sealing machine, packing machine, vacuum machine, sealing machine, electromagnetic machine, packing machine, mushrooms should be material, full automatic filling machine, cuff type packing machine, sending spot

- Q: Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q: What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q: What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

Send your message to us

FULLY-AUTO L BAR SEALER and SHRINK TUNNEL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords