Resistance welding steel machines

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

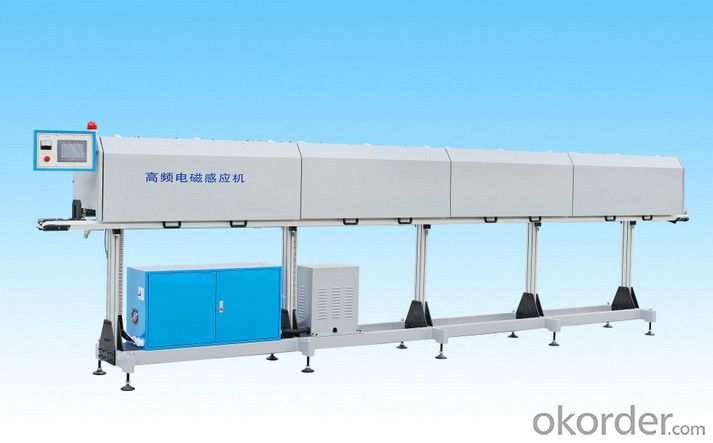

high-frequency mesh welding machine

wire mesh machine

wire diameter:4-8mm

width of mesh:1600mm

welding opening:50-300mm

fully automatic high frequency resistive welding steel reinforcing mesh machine

fully automatic wire mesh fence machine mesh welding machine welding wire machine wire mesh machine

Production of Hebei jiaoyang wire mesh machine Co.,Ltd

fully automatic high frequency resistive welding steel reinforcing mesh machine

The main parameter of high-frequency mesh welding machine

| wire diameter | 4-8mm | rated voltage | 380v |

| line wire distance | 50-200mm | rated electrical power | 8*125KVA |

| cross wire distance | 50-200mm | line wire form | coil |

| number of electrodes | 32 | cross wire form | coil |

| welding speed | 80 times/min | dimension | 3100*40000*3000mm |

| wire mesh width | 1600mm | wire mesh length | 6000mm |

The main function of high-frequency mesh welding machine

1. This high-frequency mesh welding machine adopts synchronous control technique, both welding times and seperate by digital PLC system with touch screen.

2. so that the operation is much more intelligent, reasonable and has a compression, sub-welding characteristics.

3. The aircraft welding power is from servo motor , welding speed is much faster and more stable.

4. welding pressure is provided by Nitrogen gas spring, wich is easy to adjust quikly, and the pressure is more evenly.

5. Line wire and cross wire are fed from coils. CNC sets mesh length, automatic cutting, dropping, arresting and output, which maximized saves labor and greatly increased production.

Machine application of high-frequency mesh welding machine: Mine timbering wire mesh, construction mes, reinforced mesh.

Packaging of Hebei jiaoyang wire mesh machine Co.,Ltd

fully automatic high frequency resistive welding steel reinforcing mesh machine

1. The main high-frequency mesh welding machine is apcked by plastic

2. the spare parts is packed by wooden box.

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: Working principle of packing machine

- In the first step, the wrapping paper is pulled down by a bag pulling motor, and then the paper part is supplied with paper according to the signal of the paper feeding sensor, and the wrapping paper is formed through the forming part of the shaper

- Q: What is the working principle of the pillow packing machine?

- In fact, the special machine is often better than the packaging of the compatible machine. A packing machine should be packed in no more than 3-5 varieties. What's more, the products with the larger size and the difference in size should be packed separately as much as possible.

- Q: What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Molding: mainly used for thermosetting resins. There is a special molding machine. Molding pressure is much greater than the above. The mold structure is also more complex.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

Resistance welding steel machines

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords