SEMI-AUTO L BAR SEALER and SHRINK TUNNEL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

This machine is made of shrink tunnel and sealing machine. Adopt L bar manually sealing, then automatically transit to the shrink chamber and finish the shrinking

Anti-stick high-temperature alloys L type sealing knife which can seal neatly, without cracking, coking and smoking; The sealing blade with Teflon non-stick coating layer makeshift non-sticking.

It is easy to adjust the conveyor height by the hand wheel;

Control the sealing time by time relay;

Sliding bracket can be placed all kinds of shrink film, while the punching device is smooth;

The whole sealing function of SF-20LG/B is automatically completed by cylinder which decreases labor intensity and increases working efficiency;

Sealing knife with automatic anti mistakenly cutting and anti-overheating protection device effectively protect the operator away from accidental cutting;

With emergency stop device in case of emergency situations can immediately stop the machine running;

Imported electrical components assure stable performance;

Imported heat – resistant insulation curtain greatly reduces heat loss;

Stainless steel heating elements makes warming-up fast. Large power fan motor assures big wind volume and air transported uniform. According to products’ sizes and output, you can adjust conveyor speed and chamber temperature to achieve optimal contraction effect;

Using solid roller conveyor, external anti-high temperature silicone tube can endure heavier objects and rollers will become deformed;

The machine is widely used in biscuits, printing products, pharmaceuticals, floors, pottery, boxes and other packaging fields which only need one operator and conveniently working. The packing speed is fast and improves the working efficiency greatly which specially suits for bulk products packing;

Suitable for PVC, POF, PP, OPS, PET film sealing wrapping

Parameters

Model | SF-20LG | SF-4525 |

Power | 1kw | 9kw |

Power Supply | AC220V 1/3PH 50/60Hz | AC220V/380 3PH 50/60Hz |

Max. Packing Size L×W×H | L+H≤530mm W+H≤430mmH≤200mm | 1000×300×200mm |

Tunnel Size L×W×H | / | 1000×450×250mm |

Table Height | 750±50mm | 850±50mm |

Packing Speed | 0-15m/min. | 0-10m/min |

Max. Loading Weight | 25kgs | 25kgs |

Shrink Film | POF,PVC | POF,PVC |

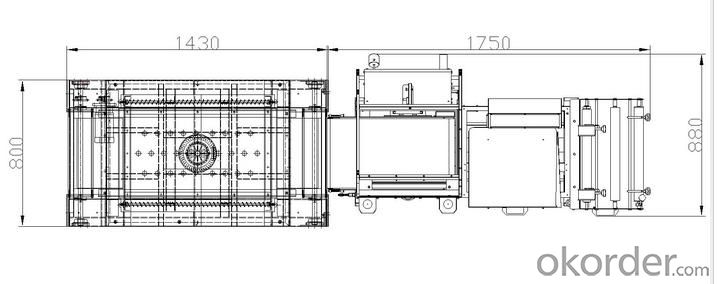

Machine Size L×W×H | 1730×790×980mm | 1300×800×1520mm |

Package Size L×W×H | 1780×840×1130mm | 1350×850×1670mm |

G./N. Weight | 155/125kgs | 320/280kgs |

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: What's the best place to use the pillow type packing machine?

- This device is now relatively mature technology, but each manufacturer's design is still a little different

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- (1) urea formaldehyde moulding powder;The resin powder of urea formaldehyde resin, commonly known as electric jade powder, is produced by wet process, such as tree ester, curing agent, filler, colorant, lubricant, stabilizer, plasticizer and so on1 Components(1) resin used for urea formaldehyde resin molding powder by condensation reaction degree is relatively shallow, the resin with low viscosity, easy dipping filler, and can ensure the long production cycle and drying after proper fluidity, condensate in the industrial use of urea and formaldehyde at low temperature (a mixture of dimethylol urea, urea and formaldehyde) are usually used. The ratio of 1:1.5 (molar ratio), the PH=8 (and temperature) 30 - 35 of all dissolved, adding urea oxalate was 0.3% - 0.33% and 0.88% - 0.54% of the oxalic acid, then the occurrence of exothermic reaction, temperature rise, temperature in 55 - 60 degrees, and strictly control the PH=5.5 - 6.5, 60 - 75min by urea formaldehyde resin is required. Because the condensation degree is low, in fact just over addition reaction, condensation reaction is mainly in the curing process.(2) the curing agent used in curing agent and pressing powder requires latent, usually oxalic acid, phthalic acid, two formic acid, benzoic acid, chloroacetic acid, etc.(3) packing material is the most commonly used pulp, followed by wood powder or inorganic fillers (glass fiber, asbestos, mica etc.). The pulp is wood as raw material, with sodium bisulfite, non soluble cellulose impurities to the wood, and then byThat is the pure cellulose bleaching. The amount of filler material for the total amount of 25%-32%, the amount is too small, the pressure of plastic powder fluidity big, product strength is low; on the contrary, the amount of excessive pressure, plastic powder fluidity decreases, the product surface is not smooth, water

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

SEMI-AUTO L BAR SEALER and SHRINK TUNNEL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords