Olive Harvest Tools 100% Virgin HDPE Tools

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

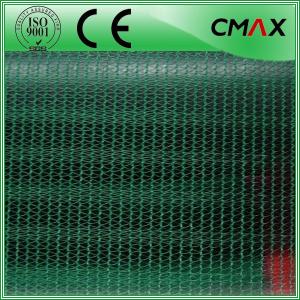

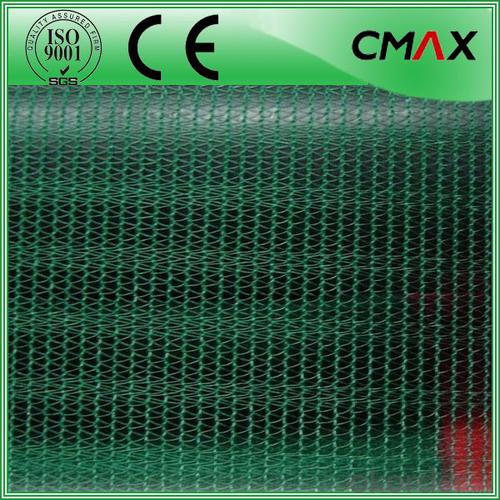

Olive Harvest Tools 100% Virgin HDPE Tools

Production Description:

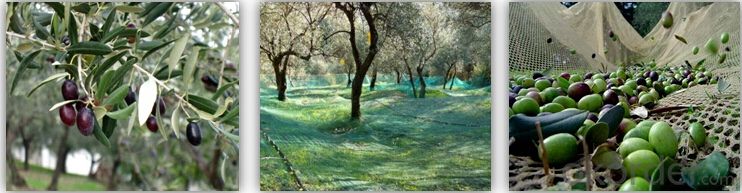

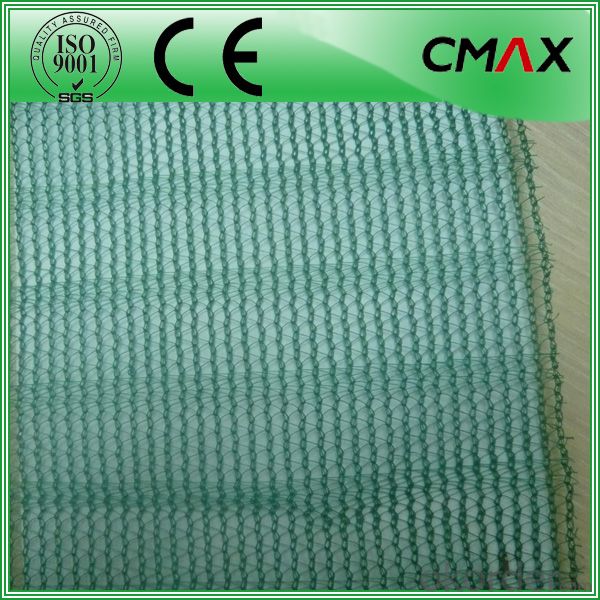

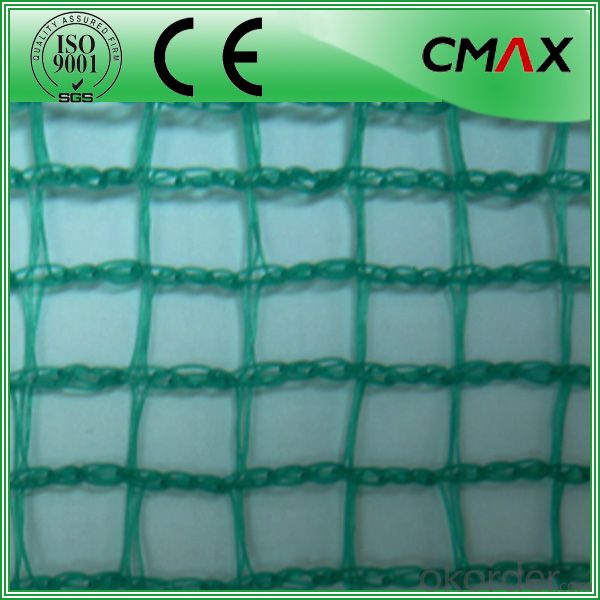

Olive collection net are used not only for the olive harvest, but also to gather chestnuts, nuts and deciduous fruits in general.

Produced with HDPE virgin material

UV stabilized - Long life

For Food : non-toxic, responsive to current European legislation on packaging for food.

Guarantee 5 years

Green&Black 50g/m2

Farmer used the net to gain olive from tree.

Specification:

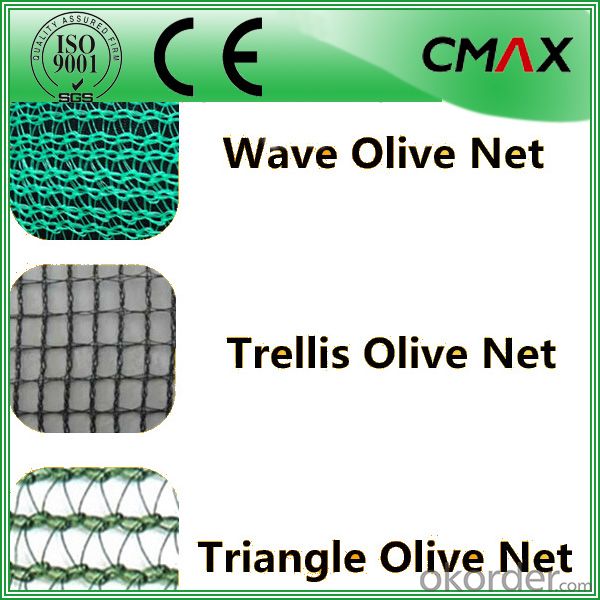

| Type | CMAX-Olive Net |

| Weight | 33-200 gsm |

| Color | Black, Green, Dark Green, etc |

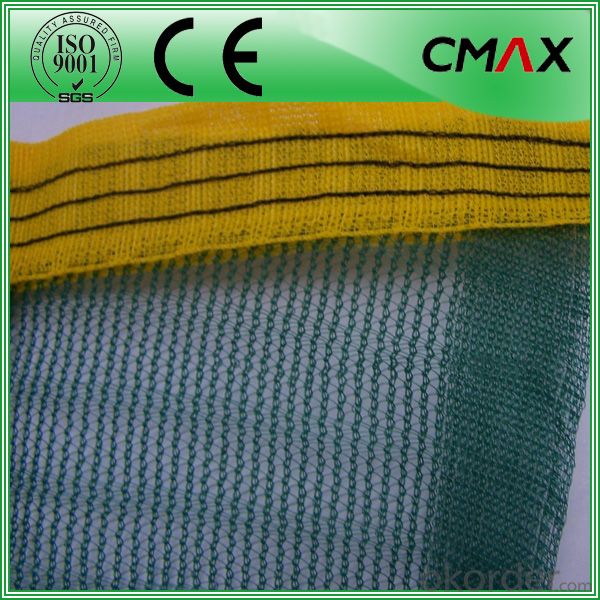

| Width,Length | 1-6m, 50m,100m as your requirements |

| Raw material | 100% Virgin HDPE with U.V Stabilized and irganox |

| Using life | At least 4 years |

| Delivery time | 30 days after deposit |

| Specification | construction(/inch) Warp=3, Weft=4.5, Br.Str.(kg) ,Warp=10, Weft=2 ,Screening factor(%) :10% |

| Packing | rolls with PVC suare tube(5×5cm)/double folded/PE Stretch film/label |

| OEM | If you have your own packing design,we can quickly meet your requirments. |

Application:

Process:

Shipping&Packing:

FAQ:

1.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shanghai, China. You can take flight to Shanghai Hongqiao airport, and 25 mins reach to our factory.

2.Q:What is the material of your products?

A: We use the raw material of High Density Polyethylene (HDPE) with UV Stabilized & Igranox to make our netting

3.Q:How does your factory do regarding quality control?

A: we are very proud to let you know that , We use the best raw material , have at least 5years experienced workers,

the advanced machine and specialized team to assure the quality

We perform Quality Control inspections on 100% of our products.

Our inspection standards are strictly in accordance with the ISO9001 certification system.

- Q: How can plastic films be recycled?

- If you want to recycle the packaging film, packaging film materials including glass paper (cellophane), PE, PVC, PP, EVA, PVDC, PA, PET and all kinds of composite films. A packing film of a single material, which can be directly made into plastic products or made into various products after being sorted and cleaned. Composite films include composite films made of different plastics, and films made of plastic and paper, aluminum foil and other materials. The recycling process after recovery is more complicated.

- Q: What are some ground cover options for high traffic areas?

- Some ground cover options for high traffic areas include turfgrass varieties such as Bermuda grass or Kentucky bluegrass, as they are highly resistant to foot traffic. Other options include creeping thyme, clover, or a mixture of low-growing plants like sedum or creeping Jenny.

- Q: Are there nursery trays with built-in drainage trays?

- Yes, there are nursery trays available in the market that come with built-in drainage trays. These trays are designed to provide proper drainage for plants, preventing over-watering and promoting healthy root growth.

- Q: This question asks about methods employed in agriculture to combat soil erosion using plastic products.

- <p>Several techniques are used to prevent soil erosion with agricultural plastic products: 1. Mulching: Applying a layer of plastic mulch on the soil surface reduces water evaporation and controls weed growth, which in turn minimizes soil disturbance and erosion. 2. Plastic film cover: This technique helps in maintaining soil moisture and temperature, reducing the need for tillage, and thus, soil disturbance. 3. Agroforestry with plastic barriers: Plastic barriers can be used to protect young tree saplings, reducing soil erosion around the plants. 4. Plastic nets: These can be used to cover the soil, protecting it from wind and water erosion. 5. Drainage systems with plastic pipes: Proper drainage helps in preventing soil erosion by reducing water runoff and soil saturation. These techniques, when used effectively, can significantly reduce soil erosion and maintain soil health.</p>

- Q: what if a person used an undertank heater for a plastic box like rubbermaid or sterilite that is home to a snake. would the plastic box release poisonous fumes or would the heater not affect the plastic? also, what are some recommendations for not putting the heater directly onto the box. i've heard that some people put the heater on a ceramic tile, and put the tile under the plastic box. thanks

- Make okorder /

- Q: What factors influence a farmer's decision between biodegradable and traditional agricultural plastics?

- <p>Farmers consider several factors when choosing between biodegradable and traditional agricultural plastics. Cost is a significant factor, with traditional plastics often being cheaper. However, the long-term environmental impact and sustainability play a crucial role, as biodegradable plastics reduce soil and water pollution. The effectiveness of the plastic in terms of durability and crop protection is also considered. Additionally, government regulations and incentives for environmentally friendly practices can sway the decision. The availability of recycling programs and the farmer's personal values regarding environmental stewardship further influence the choice.</p>

- Q: i have a plastic table outside and wanted to dress it up a bit. would it be possible to do a mosaic on the plastic table top? and what kind of adhesive would i use?

- Mosaic Plastic

- Q: Can ground cover plants be used to create a natural-looking border along water features?

- Yes, ground cover plants can be used to create a natural-looking border along water features. Ground cover plants provide a low-growing, dense coverage that helps to soften the edges of water features and blend them seamlessly into the surrounding landscape. They also help to prevent erosion, retain moisture, and provide habitat for beneficial insects and wildlife. Overall, ground cover plants are an excellent choice for creating a natural and visually appealing border along water features.

- Q: What are some environmentally friendly ways that are currently being investigated to reduce plastic waste?

- Plastic okorder / It can also be used to create new containers for non-consumable goods (non-food products, such as laundry detergent bottles).

- Q: How are plastic hay feeders beneficial for livestock nutrition?

- Plastic hay feeders are beneficial for livestock nutrition as they help reduce hay wastage by minimizing trampling, soiling, and spoilage. By keeping the hay off the ground and providing a controlled feeding environment, these feeders ensure that animals have constant access to clean and fresh hay, promoting better digestion and nutrient absorption. Additionally, plastic hay feeders help prevent the ingestion of dirt, debris, and parasites, reducing the risk of digestive issues and improving overall animal health.

Send your message to us

Olive Harvest Tools 100% Virgin HDPE Tools

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords