pp leno mesh bags for potato cabbage lemon etc

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of our factory :

We have complete working procedure:

Now have 500 employees.

Warp-making machines---3 sets

Weft-making machines---4 sets

Tubular leno mesh bags-making machines---210 sets

Plain leno mesh Bags-making machines---45 sets

pp fabric roll-hot cutting machines---4 sets

sewing machines---300 sets

bale packing machines--- 4 sets

Mesh bag for package :

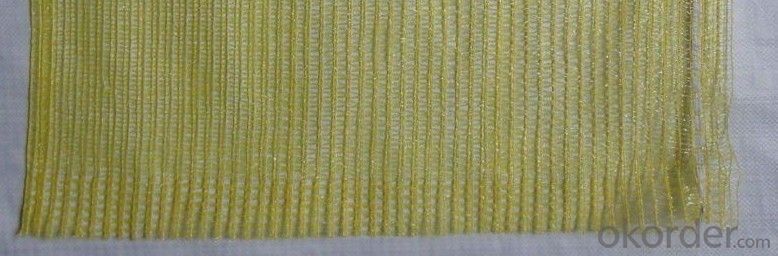

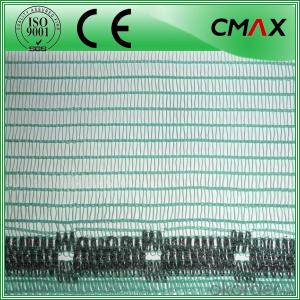

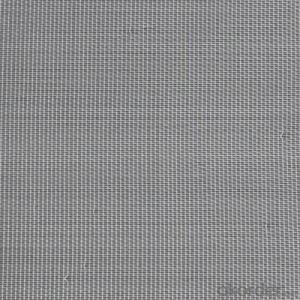

It is weaved by High-density polyethylene (HDPE/PP), used as packing vegetable and fruit, such as onion, carrot, garlic, cabbage, lemon, pecans, etc.

Based on order, other weaves are also available.

Specifications:

Material : PE/PP

Weight: 17g/bag,18g/bag,22g/bag, any weight as demands.

Size: 50×80CM, 40×60CM,42X60CM,45×75CM, any size as demands.

Feature:

1) Top: hemmed /with drawstring or without handle is available

2) Bottom: sealed., single /double folded ,single.double

3) Capacity:bags with or without drawstring for packed weight from 1kg to 55kg

Packing: 2000pcs/bale,3000pcs/bale,6000pcs/bale,Or according your requests. Container capacity: 12tons/20GP, 23tons/40GP, 25tons/40HQ.

Application:used as packing vegetable and fruit, such as onion, carrot, garlic, cabbage, lemon, pecans, etc.

About factory.

Now have 500 employees.

Warp-making machines---3 sets

Weft-making machines---4 sets

Tubular leno mesh bags-making machines---210 sets

Plain leno mesh Bags-making machines---45 sets

pp fabric roll-hot cutting machines---4 sets

sewing machines---300 sets

bale packing machines--- 4 sets

- Q: This question asks about the possible risks or negative effects associated with the use of biodegradable plastics in agriculture.

- <p>Biodegradable agricultural plastic products, while reducing plastic pollution, may have potential hazards. These include the release of methane during decomposition, which contributes to greenhouse gas emissions. Additionally, the breakdown process can release chemicals that may contaminate soil and water, affecting soil health and aquatic ecosystems. The rate of degradation can also be unpredictable, potentially leaving fragments that persist in the environment longer than intended. Moreover, the production of biodegradable plastics often requires more energy and resources, which can lead to higher carbon footprints. Lastly, improper disposal can still lead to environmental issues if these plastics end up in landfills or natural habitats.</p>

- Q: What precautions should be taken when dealing with plastic products used in agriculture?

- <p>When handling agricultural plastic products, safety measures include wearing protective gloves and clothing to prevent skin contact and irritation. Ensure proper ventilation to avoid inhaling fumes from heated plastics. Store plastics away from direct sunlight and heat sources to prevent degradation. Dispose of used plastics responsibly to minimize environmental impact. Regularly inspect equipment for wear and tear to prevent accidents. Educate workers on the correct handling and disposal of agricultural plastics to maintain safety and environmental standards.</p>

- Q: I'm very aware whats happening in our environment, I'm wondering what if the world is filled with plastic. How many years this will last?

- Plastic is non biodegradable. It is a polymer which can't be broken down by natural processes. If humans keep on producing plastic and don't bother to dispose it properly, plastic will remain as it is till the day the planet ceases to exist. However there are certain chemical reactions in labs to convert plastic into certain other stuff. These reactions require adverse conditions and don't occur naturally.

- Q: Are nursery trays suitable for starting herbs from seed?

- Yes, nursery trays are suitable for starting herbs from seed. They provide a convenient and organized way to germinate and establish herb seedlings. The trays allow for proper drainage and moisture retention, creating optimal growing conditions for herbs. Additionally, the individual compartments in nursery trays prevent root entanglement and make transplanting to larger pots or the garden easier.

- Q: How do you choose ground cover that tolerates hot, dry climates?

- When choosing ground cover for hot, dry climates, it is important to select plants that are drought-tolerant and can withstand high temperatures. Look for plants that have thick, waxy leaves or small, needle-like foliage, as these are often adapted to conserve water. Additionally, opt for plants with deep root systems that can access moisture deep below the surface. Some suitable options include succulents, such as sedums and ice plants, as well as Mediterranean herbs like thyme and rosemary. Consider consulting with local nurseries or horticulture experts who are knowledgeable about plants that thrive in your specific climate.

- Q: How do agricultural plastic products help with pollination?

- Agricultural plastic products, such as bee hives or tunnels, can help with pollination by providing a controlled environment for pollinators, like bees, to thrive. These products can attract and house pollinators, ensuring their presence during the flowering season and increasing the chances of successful pollination.

- Q: What are the different types of plastic buckets used in aquaculture?

- There are several different types of plastic buckets commonly used in aquaculture, including polyethylene (PE) buckets, polypropylene (PP) buckets, and polycarbonate (PC) buckets. These buckets are chosen for their durability, resistance to chemicals and UV radiation, and suitability for various aquaculture applications such as feeding, water storage, and transport of fish or other aquatic organisms.

- Q: How do you prevent leggy growth in a nursery tray?

- To prevent leggy growth in a nursery tray, it is important to provide adequate light for the plants. This can be achieved by placing the tray in a well-lit area or using artificial grow lights. Additionally, maintaining the proper temperature and avoiding overwatering can also help in preventing leggy growth. Lastly, regularly rotating the tray to ensure even light exposure on all sides of the plants can promote healthy and compact growth.

- Q: Are there any ground cover plants that are suitable for alkaline clay soils?

- Yes, there are several ground cover plants that are suitable for alkaline clay soils. Some examples include creeping thyme, creeping phlox, sedum, and ornamental grasses such as blue fescue. These plants are well-adapted to thrive in alkaline clay soils and can provide effective ground cover in such conditions.

- Q: Can ground cover plants prevent soil erosion?

- Yes, ground cover plants can help prevent soil erosion. These plants have dense root systems that hold the soil in place, preventing it from being washed away by rain or wind. Additionally, their foliage helps to break the impact of raindrops, reducing the force that can dislodge soil particles.

Send your message to us

pp leno mesh bags for potato cabbage lemon etc

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords