Office Furniture Commerical Desk/Table Solid Wood CMAX-BG204

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: | Office Furniture | Specific Use: | Office desk | Style: | Commerical Desk |

Material: | MDF/MFC,Melamine | Folded: | No | Color | All color are available |

Volume: | 0.19 m3 | customization: | Yes | Model | CMAX-BG204 |

MOQ | 20 sets | Warranty | 2 years | General Use: | Commercial Furniture,office desk,office furniture,for executives/directors/presidents |

We specialized in office desk and office seating .

Our factory has been engaged in office furnitur e for more than 10 years.

Our factory is wellknown in the high quality and competitive price of our products.

Therefore, we completed in specifications and win warm praise from customers.

In addition, the design of our products is deft, modern and beautiful.

There are many types and colors for your selection.

Our goods are easy and simple to handle and durable in use.

Whether you need 1 office chair or big modular furniture, we offer the service, experience and attention you deserve -no matter how big or small the job is.

Your satisfaction is our goal, that's why we only supply furniture from top brands!

From workstations to cubicles, we have them all.

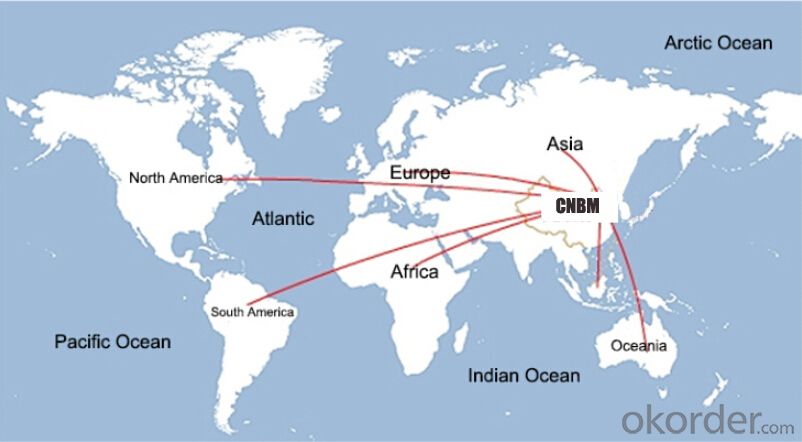

CNBM have a team of friendly and knowledgeable office Furniture and industrial furniture specialists with a specialists division who cater to our clientele who are looking for complete Office fitouts. At ROF we supply you more then just the chair or desks for your new working space, we create engaging and fresh office fitouts using our extensive range of Australia's best designs and qualities of office Furniture and industrial furniture.

Welcome any questions!

1. Features

1) Material: PU, PVC and fabric available

2) Height is adjustable

3) Rotary max. to 360

4) Slide freely with wheels

5) Designs and Patterns available upon requests

6) Different colors are available

7) Elegant design, excellent workmanship

8) Height of the seat and backrest are suitable

9) The pad thickness of the seat and backrest are suitable

2. Quality Control

1) Every product quality will be checked & cleaned before packing

2) We will try our best to help clients when problems occurred

3) Every step of production is carefully inspected by our professional QC clerk to ensure the quality of our products

CMAX-BG642

2800*1225*1060

CMAX-BG141

2825*675*1125

CMAX-BG204

1450*2825*1125

CMAX-BG821

1500*2825*1050

FAQ

Why choose us?

1, Advantage: Directly manufacturing factory with competitive price and quality control, we check all material when we start to bulk productions.

2, Professional advice to help you purchase the products you wanted/

3, Professional export service team servers in the deal.

4, Customization service is available, OEM business is appreciated.

5, We will inspect and test all products material carefully to ensure no damage and lost.

6, The success of our cooperation can be guaranteed for our company is a credible and honest partner.

How about the quality ?

1.Our normal material of MDF and MFC is with E1 standard. All oil paint we use is enviropaints. All kinds of Certification is available.Besides all the material could be customized.

How about the payment term?

1.Usually 30%T/T in Advace, the balance before shippment. L/C at sight could also be accept.

Other payment term could be discussed with specific orders.

Can you give warranty of your products?

Yes, we can supply 2 years warranty for our normal items. For the overseas orders, please provided emails with details including pictures, we will send replacements (Such as castors, screws, plastic pad of base) at our cost to repair the chairs in some coming orders.

- Q: What is the difference between laminated lumber (LVL) and plywood (plywood)?

- LVL is also called "forward" plywood. Generally, the wood fibers of each floor are in the opposite direction. In this case, the consequent forces are relatively large. For structural problems, there are a few layers that will be horizontal, such as the two floor.

- Q: What is a high pressure rubber sheet?

- Manufacture of non-polar rubber with excellent insulating properties, such as NR, SBR and IIR. A mesa or flooring insulating material used in power distribution and other work situations.

- Q: Plywood with natural red oak bark at the end of what is the reason?

- That is to say, the veneer may be too empty in the middle. White latex comes out through the hole in the middle. Pure hand. Hope to help you. I hope you can give me some points. thanks in advance

- Q: What's the difference between a plywood press and a panel press?

- Plywood hot press is one of the main equipment for plywood production process, is used for hot pressing of glue combined slab equipment, properties of different varieties of plywood press have different requirements: general aviation manufacturing plywood, plywood, veneer, wood plastic laminated plastic board, plywood vessel pressure required in turn increase. Plywood hot press according to the operation mode, divided into two types of cycles and continuous, the domestic regular is a cyclical multi-layer hot press. It consists of three parts: press machine body, control drive part (hydraulic system and electric control system), heating system.

- Q: What's the difference between plywood and plywood?

- The plywood is logs into veneer or by wood sliced veneer, with adhesive glued into three or more layers of sheet material, usually with odd veneer, and the fiber direction of adjacent plates perpendicular to each other and gluing.

- Q: What are the methods of fixing plywood?

- The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three common types of plywood plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood. The usual length and width specifications are: 1220 * 2440mm, and thickness specifications are generally: 3, 5, 9, 12, 15, 18mm and so on. The main tree species are: camphor trees, willow trees, poplar trees, eucalyptus trees and so on.

- Q: The ABS rubber plate is thicker. What tool can you use to cut it?

- There are also a few metal handle, the blade is more inclined, with a blunt can bend the body of the line broken, there is a new blade, easy to use. There are many sizes of art knives.

- Q: What is copper paper or rubber paper?

- The old saying "offset paper paper", mainly for offset (offset) using a printing press or other printing machine higher-level color printing, suitable for printing monochrome or multicolor covers of books, text and pictorial, inserts, maps, posters, color trademarks and a variety of packaging products. The offset paper is divided into special number, No. 1 and No. 2 and No. 3 according to the proportion of paper size, and has higher strength and printability. There are single and double points, as well as super pressure and ordinary light pressure two grades. Offset printing is more advanced books and periodicals, printing paper, contrast, flexibility and surface strength of higher requirements, pH should be close to neutral or weak alkaline, so as not to affect the printing of paper,

- Q: How much is the wall of punched plywood one square metre?

- The second is not economic, poor plywood, batch of putty will soon be degumming, peeling, high quality plywood prices more expensive than gypsum board, but not as good as gypsum board partition effect. Third, plywood is generally good, there are formaldehyde, not green. I hope my answer will be of some help to you.

- Q: Is the plywood good?

- Symmetry principle: single center plane plate on both sides of the water regardless of species veneer thickness, layer, manufacturing method, fiber direction and single board rate should correspond with each other, which is symmetrical on both sides of the center plane of the corresponding layer plywood the principle of equivalent stress in different directions. Therefore, when the change of veneer moisture content, its stable structure, no deformation, cracking and other defects; on the contrary, if the symmetry center plane of corresponding layer there are some differences, will make the center plane on both sides of single board stress is not equal, the deformation and cracking of plywood.Principle of odd number layer: because the structure of plywood is adjacent layer, the fiber direction of single board is perpendicular to each other, and must accord with symmetry principle, so its total number of layers must be odd number. Such as: three laminates, five laminates, seven laminates and so on. When the odd ply plywood is bent, the maximum horizontal shear stress acts on the central veneer to make it have greater strength. Even when the plywood is bent, the maximum horizontal shear stress acts on the adhesive layer, not on the veneer. It can destroy the adhesive layer and reduce the strength of plywood.

Send your message to us

Office Furniture Commerical Desk/Table Solid Wood CMAX-BG204

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords