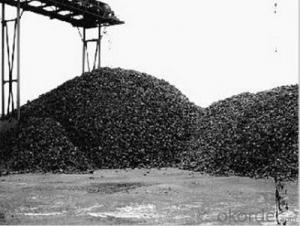

NUT COKE of 20 - 50 mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our company began to export coke whenChina cancelled 40% of coke export tariffs and quotas on January 1, 2013.

ITEM GUARANTEED REJECTION

MOISTURE (as received) 8%MAX DEDUCTION FROM B/L WEIGHT.

ASH (dry basis) 13.5%MAX ABOVE14%

VOLATILEMATTER (dry basis) 1.5%MAX ABOVE1.9%

FIXED CARBON (dry basis) 85%MIN BELOW 83%

SULPHUR (dry basis) 1.0%MAX ABOVE1.3%

SIZE: 20-50MM 90%MIN

(-) 20MM 5%MAX ABOVE10%

(+) 50MM 5%MAX ABOVE10%

Atpresent, the main customers are NOBLE GROUP, IMR and so on. Our main overseasmarkets are Japan, India, Brazil, Iran, Vietnam, and so on.

Let me know your demands then I can check availability.

- Q: Coke is how to produce, what is its purpose?

- Under the condition of air isolation, the bituminous coal is heated to 950-1050 DEG C, which is finally made into coke by drying, pyrolysis, melting, bonding, solidification and shrinkage. Coke oven gas produced in the process of coking and recovery is not only a high calorific value of fuel, but also an important industrial raw material for organic synthesis.

- Q: What is cokeWhat applications are, what is the fire of Malachite copper

- Malachite is a kind of copper, copper smelting with coke burning malachite is under high temperature.

- Q: What is the phosphorus content in coke

- Generally, the phosphorus content of coke is low, about 0.02%.The bituminous coal is heated to 950-1050 DEG C under the condition of air isolation

- Q: What is the difference between coke and carbon residue? Coke is a high-temperature refining, carbon residue can be used for civilian fuel it?

- Coke concept:Bituminous coal in the absence of air is heated to 950-1050 DEG C, after drying, pyrolysis, melting, bonding, curing and contraction of the final stage of this process is made of coke, coking high temperature (high temperature carbonization). By high temperature coking coke for blast furnace smelting, casting and gas generated in the process of coking. After the recovery and after the purification of coke oven gas is not only a high calorific value of fuel, and is an important raw material for organic synthesis industry. Metallurgical coke is coke, coke, iron alloy coke and non-ferrous metal smelting coke for metallurgical coke collectively. More than 90% were used for blast furnace ironmaking blast furnace coke, so often referred to as metallurgical coke is coke. The special cupola molten iron and coke. Coke is the main fuel cupola molten iron. It is melting charge and molten steel overheating, the support column to maintain its good permeability. Therefore, coke should Have large blocks, low reactivity, porosity is small, with impact crushing strength, low ash and sulfur enough.

- Q: What are the requirements for coke and other accounts?

- 4, I personally set the password and password.5, the customer I own the bank transfer agreement, my ID card, bank debit card to the corresponding bank outlets for bank transfer procedures.6, the day of the day to accept the phone call Futures Company visit, after the successful return of T+1 days of commodity futures trading.7, the customer into the gold (silver period transfer; non bank transfer).8, customer online transactions (start trading).

- Q: What's the connection between coking coal and coke

- Coking coal is divided into two categories, the first category of coking coal dry ash free volatile Vdaf>10% ~ 28%, G>65 bond index, thickness, y = 25mm. This part of the coking coal is particularly good, can separate the qualified blast furnace coke. Another kind of coking coal dry ash based volatile Vdaf>20% ~ 28%, caking index G>50 ~ 65, coking than the former difference. Coking coal is a kind of typical coking coal, which has a good thermal stability

- Q: Coke and coal is one thing

- How coal is formedCoal has been hailed as the black gold, the food industry, it is one of the main sources of energy used in the human world since eighteenth Century. Although its important position has been replaced by oil, but in the future for a long period of time, due to the exhaustion of petroleum, inevitable decline, but because of the huge reserves of coal, coupled with the rapid development of science and technology, the new technology of coal gasification is becoming more mature and widely used, coal will become one of the human production life cannot substitute energy.

- Q: What is the difference between the industrial analysis of coke and the industrial analysis of coal samples

- There are also ISO and ASTM, I do not know what you want the standard?

- Q: What is the difference between coke and semi coke in ferrosilicon smelting process? In the process of energy statistics in the end should be 0.9714 of the conversion coefficient should be used with the conversion coefficient of 0.75 x 0.9714, please expert advice? emergencyUrgent!

- Coke is used for smelting iron alloy coke, and the coke is used in blast furnace and used for copper, lead, zinc, titanium, antimony, mercury and other non-ferrous metal smelting of blast furnace, reducing agent, heating agent and columnar skeleton.

- Q: What does the M40% and M25% mean in the analysis of coke?

- M40% and M25% represent the breaking strength rate, 40%>25%, which means that the M40% coke is more resistant than M25%

Send your message to us

NUT COKE of 20 - 50 mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords